At Enerquip, we have a wealth of experience working with highly viscous products like asphalt, spanning decades of dedicated work. If you’re seeking an effective solution to heat your asphalt, you may be wondering whether a shell and tube heat exchanger or an asphalt heater is the better choice. We’re here to guide you through the benefits and options of both.

Shell and Tube Heat Exchangers for Asphalt Heating

When it comes to heating asphalt, shell and tube heat exchangers can certainly be a viable option. However, to handle the extreme temperatures and corrosive nature of asphalt, the heat exchanger must be expertly designed and constructed with the highest quality materials.

Using a shell and tube heat exchanger to heat asphalt allows for flexibility in design, as you can choose to place the asphalt on the tube side using larger diameter tubes, or on the shell side using baffles to carefully direct the fluid flow. In either case, the opposite side would utilize hot oil or steam to generate the necessary heat to maintain fluidity.

It’s important to note that due to the harsh conditions involved, both the tubes and shell of the heat exchanger must be constructed with materials that are up to the task. Common choices for tube materials include stainless steel, carbon steel, and alloy steel, while carbon steel or stainless steel are often utilized for the shell.

Advantages of Shell and Tube Heat Exchangers

Versatility. Shell and tube heat exchangers offer unmatched adaptability, as they can be tailored to fit virtually any application and space requirements.

Corrosion Resistance. At Enerquip, we craft our shell and tube heat exchangers using durable materials such as carbon steel, stainless steel, and high-grade alloys, ensuring exceptional resistance to corrosion and wear.

Code Stamped. Our shell and tube heat exchangers are engineered in accordance with the most rigorous industry standards, including TEMA C, B, or R and ASME code, ensuring safety, reliability, and compliance.

Customization. With Enerquip, customization is only limited by your imagination. From heavy-duty davit arms and hinge assemblies to insulation jackets, saddle supports, vacuum breakers, and beyond, we can customize your shell and tube heat exchanger to your unique specifications.

Designing a Shell and Tube Heat Exchanger for Asphalt Applications

The design of an efficient heat exchanger for asphalt requires careful consideration of the fluid’s viscosity, which can impact flow rate and pressure drop. To maximize heat transfer efficiency and minimize pressure drop, it is important to optimize the tube size, layout, and velocity of the heat transfer fluid.

To achieve these goals, the following design features are commonly implemented for highly viscous products:

- Baffles are used to direct the flow of the product.

- Increased spacing between tubes minimizes fouling and simplifies cleaning.

- Square tube patterns are utilized on removeable bundles, reducing the risk of fouling and allowing full cleanability of the shell-side via hydro-blasting.

- Increased tube diameter decreases fluid velocity, leading to lower pressure drop when the pump hydraulics may be a limitation.

- Increasing the number of tubes increases the surface area for heat transfer.

- Counter-current flow design provides the highest temperature difference at the point of exit.

- Increasing turbulence in the flow enhances heat transfer efficiency.

In addition to proper design, regular maintenance and cleaning are essential for the longevity and efficient operation of the heat exchanger. Regular inspections and cleaning prevent buildup of asphalt or other debris that can reduce heat transfer efficiency and damage equipment.

Asphalt Heaters for Asphalt Heating

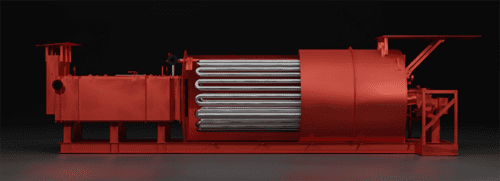

Asphalt heaters are used for heating asphalt, tar, A/C 20, blown asphalt used in roofing and shingle production, and other viscous liquids. They operate by directly heating the asphalt flowing through the serpentine coil pipe, and the flue gas from a burner flows over the pipe and helical fins.

Advantages of Industrial Asphalt Heaters

Single heat source. While many upgrades can be made at our customers’ request, often asphalt heaters are a stand-alone piece of equipment. Because it has its own direct-fired heat source, there is no need for a hot oil system, steam generator, expansion tank or heating media valves, saving your overall footprint and investment.

Fast heating times: Asphalt heaters are designed to heat asphalt quickly and efficiently, which can help reduce downtime and increase productivity.

Lower Operating Costs. Enerquip’s asphalt heaters typically operate at efficiencies higher than 86%. To enhance the heat transfer coefficient, we also size for minimum velocities of eight feet per second. This setup ensures the film temperature is kept below the coking temperature of the asphalt, while the larger pipe sizes also alleviate the risk of plugging.

Serpentine Coil. In the radiant section of the heater, heat is transferred to the front, sides and back of the serpentine coil. This allows for more even heat distribution, less coil degradation, longer tube life, and higher operating oil temperatures.

Helically Finned Pipes. The finned pipes in the convection section (economizer) significantly enhance the surface area, allowing the flue gas to flow around the pipes and for the asphalt heater to utilize a minimal number of pipe rows.

Economizer Built-In. To further enhance efficiency, our asphalt heaters come with a specially engineered economizer built in. This addition can increase the overall heater efficiency by up to 10%.

Asphalt Heating Solutions from Enerquip

Elevate your asphalt heating solutions with Enerquip. Our top-of-the-line asphalt heaters and shell and tube heat exchangers are expertly designed for maximum quality and durability. By minimizing downtime and operational costs, our products are the ideal choice for any asphalt heating application.

Let us customize a solution tailored to your specific needs. Contact us today or request a quote to experience the Enerquip difference.