Process Cooling: The Salsa Cooling Challenge

Leave a CommentA custom heat exchanger design allows a salsa manufacturer to effectively complete process cooling of the product and expeditiously clean-in-place between batches and shifts.

California-based Southwest Thermal Technology was approached by one of its OEM customers to provide a shell-and-tube cooler to chill a client’s salsa prior to bottling. The request was more challenging than it sounds.

The Challenge

Because of the viscosity of the salsa — around 2,000 cP while warm and much thicker at 9,165 cP when cooled — turbulent flow was extremely difficult to achieve in the tubes of a shell-and-tube heat exchanger. The viscous salsa hindered efficient heat transfer. Typically, this situation is addressed by using a heat exchanger with more surface area while using a high volume of cooling water on the shell side of the heat exchanger. Such a design could achieve process cooling from 200 to 120°F (93 to 49°C).

Southwest Thermal Technology wondered whether a more compact solution was possible. That’s when they reached out to Enerquip.

After reviewing the problem, the engineers at Enerquip first considered a single, large heat exchanger that would perform well thermally. But the single large exchanger would be difficult to clean with the salsa maker’s clean-in-place (CIP) system. Typically, CIP works best when the cleaning solution can be circulated at 5 ft/sec or more. In a single, large exchanger, this would not be achievable.

Of course, in food production environments, it is crucial to keep process equipment like shell-and-tube heat exchangers clean and sanitary. Regular CIP cleaning takes place between batches or shifts. This prevents cross-contamination of different products between batches and prevents unwanted bacterial growth that could contaminate food products.

A New Approach

The design team at Enerquip then developed a new approach. Process cooling of the salsa would occur by flowing through three smaller heat exchangers stacked in series. The salsa would pass from one heat exchanger to the next traveling through a sanitary jumper, which connected the outlet of the first exchanger to the inlet of the second exchanger, and likewise for the second-to-third exchanger connection. Meanwhile, the cooling water would flow counter-current from shell to shell, starting in the third exchanger, flowing through the second exchanger, and finally through the shell of the first unit.

To realize this process cooling solution, three unique shell designs were created. They allowed the connecting flanges between each shell to be bolted together for the chilled water flow. Tube-side connections included an additional CIP connection on the first bonnet for the inlet and on the last bonnet for the outlet. CIP flow through the other bonnets used the jumper connections for the salsa to further reduce the piping costs and complexity.

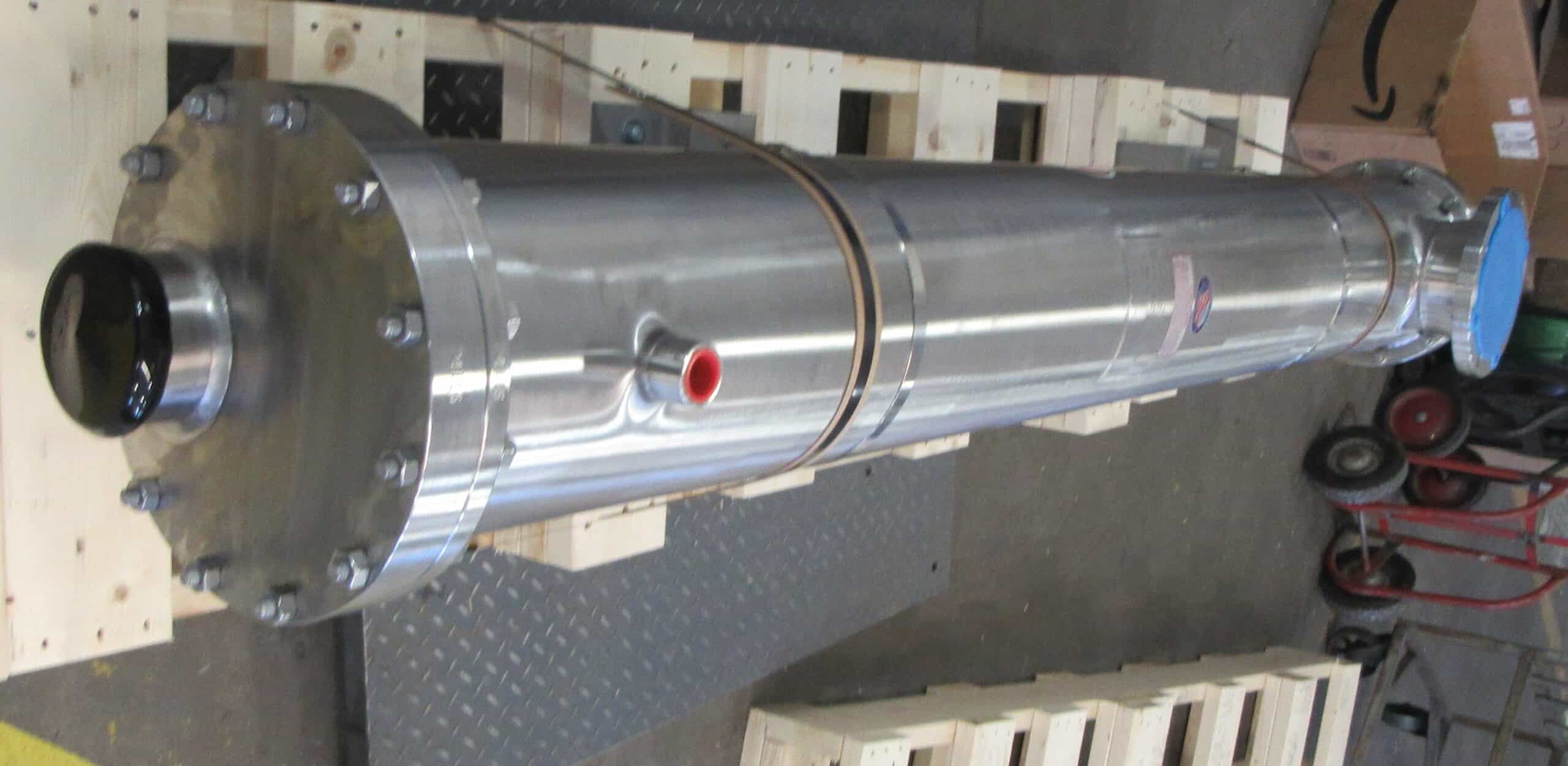

Enerquip Salsa Coolers – Stacked Set

This design allowed for more efficient process cooling. In addition, the reduced exchanger size allowed the units to be cleaned effectively using the customer’s CIP system at 5 ft/sec flow through the tubes.

Because of the acidity of the salsa, the salsa maker opted to use a higher stainless alloy for the tubes and other product-contact surfaces of the exchangers. While more expensive, super-austenitic stainless steel is more resistant to corrosion from acids and cleaning solutions.

Another benefit of the three smaller, stacked exchangers over one larger exchanger was risk avoidance. If there was ever a tube failure in the single large exchanger, the customer would potentially be shut down completely during a repair, and the entire tube chest would need to be replaced. This would take months to achieve due to the lead-time on super-austenitic tubing. By using three smaller shell-and-tube heat exchangers in series, the salsa maker has equipment redundancy. Any of the units can be temporarily bypassed if there were a tube failure. Replacement of a smaller tube chest would be less than the cost of a single, larger one.

Through this approach, the salsa maker was able to get more consistent process cooling and meet all the sanitary requirements for cleaning their equipment. As an added benefit, the company gained flexibility and redundancy while minimizing the risk of costly downtime.

Article published in Process Cooling magazine: July 2019.

Article Author: Jim Peterson, Enerquip Sales Engineer