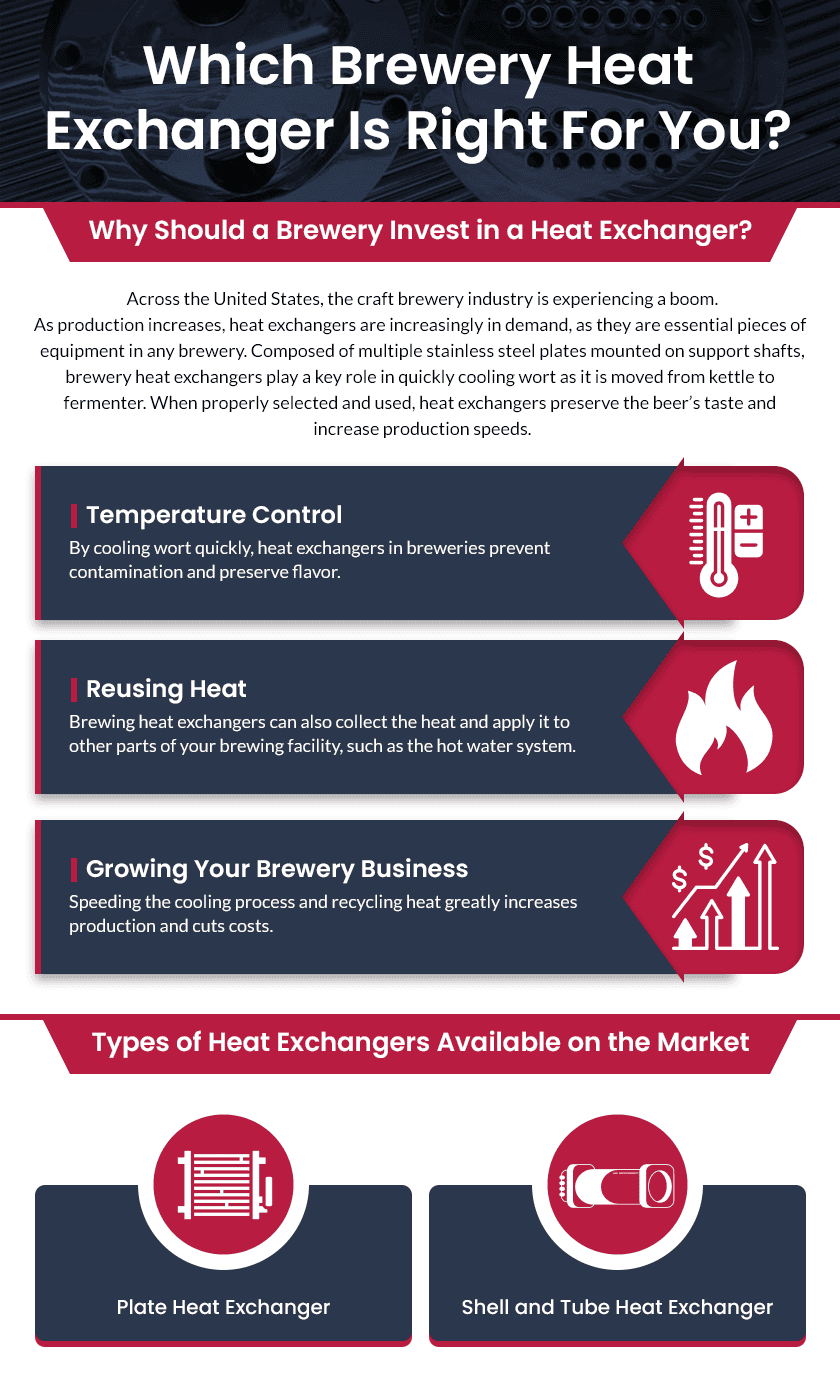

Across the United States, the craft brewing industry is experiencing a boom. As production increases, heat exchangers are increasingly in demand, as they are essential pieces of equipment in any brewery.

Brewery heat exchangers play a key role in quickly cooling wort as it is moved from kettle to fermenter. When properly selected and used, heat exchangers preserve the beer’s taste and increase production speeds.

Why Invest in a Heat Exchanger?

Wort must be cooled quickly to prevent bacteria and dimethyl sulfide (DMS) from tainting the initial brew. Brewery heat exchangers accomplish this goal by reducing cooling time to as little as 45 minutes. Proper control of heat is essential to any brewing process for the following reasons:

Temperature control. By cooling wort quickly, heat exchangers in breweries prevent contamination and preserve flavor.

Reusing heat. Brewing heat exchangers can also collect the heat and apply it to other parts of your brewing facility, such as the hot water system.

Growing your brewery business. Speeding the cooling process and recycling heat greatly increases production and cuts costs.

Types of Heat Exchangers for Brewing

Selecting the right brewery heat exchanger requires knowledge of the different types available.

Plate & Frame Heat Exchangers: Several metal plates are placed in direct contact with the brewing tank, transferring heat from one fluid to another. The cooling medium and beer flow through the plates in opposite directions on separate flow paths.

Shell and Tube Heat Exchangers: A series of parallel tubes send the wort and the cooling medium past each other in opposite directions. Heat exchange takes place between the tube walls.

Why Shell and Tube is the Better Option

In the brewing industry, both shell and tube heat exchangers and plate and frame heat exchangers can be used for heat transfer, but there are several reasons why shell and tube heat exchangers are often a better option.

- Better for viscous fluids: The brewing process often involves fluids with high viscosity such as wort, which can cause fouling or blockages in plate and frame heat exchangers. Shell and tube heat exchangers, on the other hand, can handle such fluids more efficiently, making them a better choice for the brewing industry.

- Tolerates high and low temperatures: Shell and tube heat exchangers are designed to operate in a wide range of temperatures, making them suitable for a variety of applications. They can handle both high and low temperatures without compromising the performance of the heat exchanger.

- Resistant to thermal shock: Shell and tube heat exchangers are made of durable materials that can withstand thermal shock. This is important because sudden changes in temperature can cause damage to the heat exchanger, leading to leaks or other issues.

- Better for higher flow rates: In the brewing industry, there is often a need for high flow rates. Shell and tube heat exchangers are better suited for these higher flow rates, as they can handle more fluid than plate and frame heat exchangers.

- Customizable size: Shell and tube heat exchangers are available in a range of sizes and configurations, making them customizable to fit the specific needs of different applications. This allows for greater flexibility in designing a heat exchanger system that can meet the specific requirements of a particular application.

- Easy assembly and disassembly: Shell and tube heat exchangers are relatively easy to assemble and disassemble, making them easy to install or remove when necessary. This is particularly important in applications where the heat exchanger may need to be taken apart for cleaning or maintenance.

- Easier to clean: Cleaning is an important part of the brewing process, and shell and tube heat exchangers are generally easier to clean than plate and frame heat exchangers. Plate and frame heat exchangers have many small channels that can be difficult to clean thoroughly, while shell and tube heat exchangers have larger tubes that are easier to access for cleaning.

- More durable: Shell and tube heat exchangers are generally more durable and have a longer lifespan than plate and frame heat exchangers. This is because plate and frame heat exchangers are made up of many small parts that can wear out or break over time, while shell and tube heat exchangers have fewer components that are less likely to fail.

- More cost-effective: Due to their simple, flexible design, shell and tube heat exchangers are the more cost-effective option for most breweries.

Heat Exchanger Design Characteristics

When designing your brewery’s heat exchanger, you’ll want to consider these design characteristics.

Flow Configuration

Flow configuration will influence the efficiency of your overall system:

Concurrent flow brewery heat exchangers move fluids parallel to each other and in the same direction, which provides the highest level of thermal uniformity but less efficiency than a countercurrent system.

Countercurrent flow systems move fluids antiparallel to each other (opposite directions through parallel tubes), resulting in greater heat transfer efficiency between the two liquids.

Crossflow heat exchanger tubes are routed perpendicular to each other and are less efficient than countercurrent systems but more efficient than concurrent systems.

Hybrid flow heat exchangers use any combination of the above three flow configurations.

Construction Method

The types of materials used to construct heat exchangers range from various metals to ceramic, graphite, or composite materials, each with its own advantages and disadvantages. There are also different build methods, such as:

Recuperative vs. regenerative: Recuperative heat exchangers house each liquid in its own tube, while regenerative heat exchangers use one tube to transfer cool and warm fluids at alternating times.

Direct vs. indirect: Recuperative heat exchangers can transfer heat either directly or indirectly. Direct contact heat exchangers do not separate fluids within the device, so heat transfers through direct contact. Indirect contact heat exchangers separate and transfer heat between fluids using thermally conductive materials, such as tubes or plates.

Static vs. dynamic: Regenerative heat exchangers can either be static or dynamic. Static regenerators feature materials and components that stay in place while fluids flow through them. Dynamic regenerators have components and materials that move during heat transfer.

Heat Transfer Mechanism

Heat exchangers use either a single-phase or two-phase heat transfer mechanism. Single-phase heat exchangers process fluids that remain the same state of matter throughout the heat transfer process. Two-phase heat exchangers change either one or both liquids to a gas, or vice versa.

Design Considerations

Before investing in a heat exchanger for your operation, consider these factors as you plan your design:

- Cost

- Energy consumption

- Space consumption

- Maintenance needs and costs

- Scalability

Sanitary Heat Exchangers from Enerquip

Since 1985, Enerquip has been an industry leader in fabricating industrial heating and cooling equipment. Our engineers are standing by to help you design the optimal shell and tube heat exchanger for your brewery needs. Contact us with questions or request a quote today.

More from the Enerquip Blog

- Enerquip Testimonial: New Glarus Brewing Company

- Why careful wastewater treatment for breweries matters

- 2 Ways Shell and Tube Heat Exchangers can Reduce Energy in Breweries

- Shell and tube heat exchangers are used to cool wort in craft brewing

- Microbreweries gaining ground in the beer making industry