Spring is when contractors are ready to pave and roof, so your asphalt plant needs to be ready to work! If you want your facility to be in top shape when the busy paving and production season rolls around again, now’s the time to take action.

Winter is typically a slower time for most asphalt facilities, but it’s also the ideal time to focus on ensuring that your plant is well prepared to keep pace with your clients and customers during the busy season ahead.

Want to stay ahead of the game and avoid unexpected downtime when asphalt contractors are relying on you most? Here are some recommendations to help you make sure your asphalt plant heating equipment is ready to go when the paving season begins.

How to Prepare Your Asphalt Plant for Success During the Off-Season

If your asphalt plant relies on industrial thermal fluid heating equipment, there are a number of steps you can take during the off-season to minimize downtime during your busier times of the year.

Here are a few of the ways you can prepare your asphalt heating systems for a busy and productive spring.

1. Stay On Top of Maintenance

Your equipment may not be operating at 100% capacity during the off-season, but that doesn’t mean you should be lax about regular maintenance. In fact, the winter is a great time to ramp up your industrial asphalt heating system maintenance routine.

With less time spent on meeting client and contractor needs you can spend more time on general upkeep. This can help to get your equipment ready for another busy season, and can help establish a thorough maintenance routine that will keep your facility firing on all cylinders when it really counts.

Find helpful thermal fluid heater maintenance tips, for the off season and year-round, here.

2. Handle Repairs

The off-season is a great time to handle repairs because facility downtime won’t cost you as much. If you know a repair is impending, or you’ve been putting off replacing a certain element of your industrial heating system, winter is the time to do so.

We recommend doing a thorough analysis of your system as your busy season is winding down, making note of any parts that may need repair and components that may need maintenance. Make tackling these items a priority during the off-season.

3. Take Steps to Increase Plant Efficiency

There are many ways you can increase your asphalt plant’s efficiency. If you’re hesitant to move forward with these initiatives and efforts during the busy season because you need all hands on deck to keep production flowing smoothly, the off-season is a great time to do so.

Take your asphalt plant to the next level with these 9 tips for increasing asphalt plant efficiency.

4. Tackle Heating Equipment Replacement

There comes a time when replacing an industrial asphalt heating system is better than continuously repairing it. If you suspect that your facility is in this position and that a system or system component replacement may be necessary, the off-season is the time to tackle it.

Replacing industrial heating equipment seems like a gargantuan task, but trust us – it’s much better for your facility, your clients, and your business if you handle it during the off-season. By avoiding long term outages during the spring, you’ll sacrifice fewer profits and inconvenience fewer customers.

5. Shop Your Asphalt Heating Equipment Options

If you do need new asphalt heating equipment, the off-season is the time to shop for it. It can be a time-consuming project to research systems, collect quotes and estimates, and ultimately choose the right equipment for your plant. Spend this time while you have it during the winter, rather than during the busy months of the year when many other things are demanding your attention.

In the market for new heating equipment for your asphalt plant? You may find the following resources helpful as you shop your options:

Important Questions to Ask When Shopping For Industrial Thermal Fluid Heating Equipment: This list of questions is a good starting point as you’re exploring your options when it comes to industrial heaters and equipment providers.

Factors to Consider When Shopping For an Industrial Heating System: Determining exactly what you need can be a challenge. We break down the key factors to consider as you’re weighing your options.

What To Look For When Choosing an Industrial Heating Equipment Provider: Who you buy from is often just as important as the heater you choose to buy. Find out what traits to look for when it comes to trustworthy, reliable heating equipment manufacturers.

6. Implement a Spare Parts Management Program

Stocking spare parts can save your facility thousands of dollars if you do happen to experience equipment failure during your busy season. Having replacement parts on hand can make repairs faster and less expensive. Though you may not be prepared for every repair, you can be ready for some, keeping you ahead of the game.

The off-season is a great time to implement a spare parts management program if you don’t already have one, and to bolster your facility’s existing program if you do.

Position Your Asphalt Plant for A Successful Production Season

If you want your asphalt plant to be firing on all cylinders when the busy spring season comes around, it’s in your best interest to put the work in during the off-season. The key? Focusing on prevention and preparation – preventing issues that could cause significant downtime and preparing for issues that may arise when you’re operating at full capacity.

As spring approaches, try to work out the kinks. Launch systems extra early so machinery is ready to go and running smoothly when business picks up and contractors are relying on you. Be prepared to get the job done – and done well.

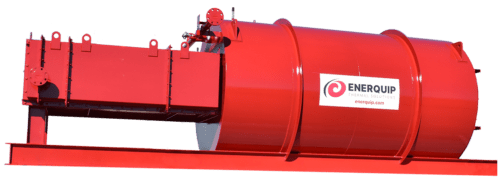

In need of new heating equipment for your asphalt facility? We can help! Learn more about our asphalt process heating solutions here.

Looking for an asphalt heating equipment quote specific to your facility’s needs? Contact us online to request an estimate, or give us a call at (715) 748-5888 to discuss what your asphalt plant needs when it comes to an industrial heating system.