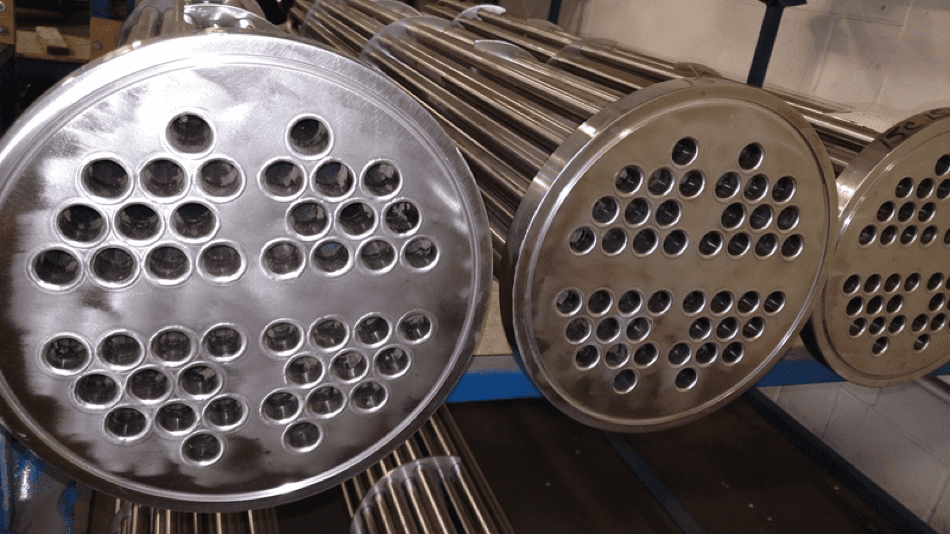

5 Smart Maintenance Tips to Keep Your Shell & Tube Heat Exchanger Performing at Its Best

Leave a CommentWhether you’re in the middle of a busy production season or just wrapping up a cleaning cycle, one thing’s for sure: keeping your heat exchanger in top shape should always be on your radar. A well-maintained unit runs more efficiently, lasts longer, and helps you avoid costly downtime or product contamination.

So, what does smart maintenance actually look like for a shell and tube heat exchanger? Let’s break it down with five practical tips you can apply year-round.

1. Schedule Routine Maintenance (and Stick to It)

Heat exchanger maintenance usually means taking the equipment offline—so yes, it can feel like a disruption. But planning ahead makes a huge difference.

- Pick a date during lower production periods.

- Order gaskets or replacement tube bundles well in advance.

- Coordinate with contractors early—don’t wait until their calendars are full.

Skipping scheduled maintenance often leads to bigger problems later. Either you plan the downtime, or the downtime picks you. Spoiler alert: the latter is never convenient.

2. Keep an Eye on Fouling and Corrosion

A fouled exchanger is a slow exchanger. Material buildup reduces heat transfer, invites corrosion, and in worst-case scenarios, becomes a fire risk. Inspect regularly—both the tube side and the shell side—for signs of scaling, sediment, or corrosion.

If you catch fouling early, cleaning is quicker, easier, and less disruptive.

3. Monitor Your Heat Transfer Fluid (HTF)

Chemical-based HTFs don’t last forever. Over time, they degrade, lose efficiency, and can even become hazardous.

To stay ahead of issues:

- Test the fluid while the system is running (hot fluid tells a truer story than cooled samples).

- Take samples from different points in the system.

- Consider quarterly testing for consistent insight into fluid health.

Healthy fluid means better performance and a lower risk of costly issues.

Test the fluid periodically; Processing Magazine noted that quarterly testing typically provides the best results.

4. Bring the Right People to the Table

Maintenance is a team effort. Involve your safety team, maintenance crew, and contractors from the beginning.

- Use checklists to stay organized.

- Share documentation in advance—like safety policies, maintenance logs, and OEM manuals.

- Require credentials and training records from any outside vendors.

Clear communication ensures your maintenance day goes smoothly, safely, and efficiently.

5. Don’t Skip the Post-Cleaning Details

Once you’re done cleaning, finish strong:

- Rinse out leftover chemicals or debris—especially after chemical cleaning.

- Inspect gaskets and gasket covers. Replacements are inexpensive, but failures aren’t.

- Document what was done and note any issues to watch going forward.

This final step is easy to overlook but critical for protecting product quality and keeping the exchanger sealed tight.

Keep Your Equipment (and Your Business) Running Smoothly

Routine maintenance might not be glamorous, but it’s one of the smartest investments you can make in your operation. Want help planning your next maintenance cycle, ordering spare parts, or upgrading your equipment?

The heat exchanger pros at Enerquip are here to help—contact us anytime.