Thermal Fluid Heater Operation

Thermal fluid heaters, also known as hot oil heaters, are used to heat fluids in a closed loop system. They work by using a heat transfer fluid, typically a mineral oil or synthetic oil, that is heated by a burner. The heated fluid then circulates through a closed loop system, transferring heat to the target material or process.

Thermal fluid heaters are essential to the day-to-day operations of facilities in the asphalt industry, refinery industry, tank terminal industry, wastewater treatment industry, food and beverage, and beyond. Organizations in these, and other, industries rely heavily on thermal fluid heaters and hot oil heating systems to get the job done.

Unfortunately, many facilities are operating heating equipment that’s not as efficient or functional as it could be. As a result, they struggle with heating equipment breakdown and inefficiency, experiencing problems like process fluid degradation, tube failures, high stack temperatures (800° F or higher), high fuel costs, high maintenance costs, and limited operation at fluid temperatures over 400° F. Without systems operating at peak efficiency, they’re also experiencing significant decreases in profitability.

If any of the problems mentioned above are currently impacting your organization, it’s time to consider a high efficiency thermal fluid heater or heating system from Enerquip.

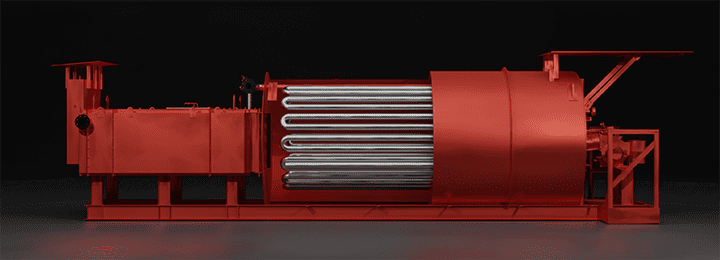

12M Btu/Hr. Hot Oil Heater

Reliable, Efficient Industrial Thermal Fluid Heaters Made in the USA

Specializing in the design of high-quality thermal fluid heaters and heating systems, Enerquip has the products to meet your industrial heating needs. With decades of experience, our finely engineered heating systems can eliminate problems and deliver the highest fuel efficiency attainable today.

Enerquip’s Thermal Fluid Heating Systems come standard with:

- High-efficiency serpentine coil radiant section

- Finned convection (economizer) section – fins add 10% efficiency!

- 1,000-gallon expansion tank

- Recirculation pump

- NEMA 4 control panel

- Fuel train

- Sizes ranging from 1.3 MM BTU/Hr. to 40 MM BTU/Hr. Need something larger? Let’s talk.

Serpentine Coil Technology

Enerquip’s serpentine coil heaters are synonymous with fuel efficiency. With a standard finned tube economizer section, efficiencies of up to 90% L.H.V. can be achieved without the use of air preheat.

Our customer-preferred serpentine coil thermal fluid heaters provide many enhancements over the more traditional helical coil heater, including:

- Even heat distribution

- Less oil degradation

- Longer tube life

- Higher operating oil temperature

- Easy maintenance

- Long-lasting

With today’s uncertain and often skyrocketing fuel costs, one of our units can pay for itself in a little more than one year when replacing an older, inefficient unit. Many of our customers have Enerquip thermal fluid heaters working hard for nearly 30 years! Learn more about the benefits of our innovative serpentine coil technology here.

Thermal Fluid Heater Applications

Industrial thermal fluid heaters from Enerquip can be utilized in a wide variety of applications and industries, some of which include:

- Alkyd paints and resin kettle heating

- Asphalt preheating

- Biofuels blending

- Chemical process heating

- Hot oil steam generation

- Lube oil and fuel oil heating

- Petroleum refining

- Rubbers, plastics and paper processing heat

- Tanker and barge heating

- Tank Terminal heating

- Synthetic fiber production surface coatings curing

Some organizations in these industries still rely on steam boilers to meet their industrial heating needs. If you are one of these organizations and you’re thinking of switching to thermal fluid heat, we highly recommend you make the switch. Find out why hot oil is better than steam for industrial heating.

Low NOx Heater Design

Whether it’s due to regulatory requirements, permitting restrictions, or green initiatives, Enerquip can help you meet your low NOx goals.

Our heaters can achieve less than 30 PPM with an upgraded burner and flue gas recirculation, or less than 9 PPM with an ultra-low NOx mesh head burner.

Learn more about our efficient Low NOx heaters and heating systems.

Start-up Support

When it’s time to install your new industrial heater, rest assured you’re not in it alone. At Enerquip, we provide startup support for our thermal fluid heaters and asphalt heaters. This includes a review of installed work and lines, supervision of the filling system, circulation of the oil, testing of circuits and safeties, bringing lines online, troubleshooting, and training on monitoring and operation of the system.

For the Best in Industrial Heaters, Choose Enerquip

If you’re considering replacing or upgrading some of your industrial heating equipment, Enerquip can help! Our team of skilled engineers can work with you to assess your industrial heating needs and design a customized thermal fluid heater that will increase your plant’s efficiency. We would be pleased to have one of our engineers review the operation of your existing heater and calculate your potential fuel savings when replacing the heater with a high-efficiency Enerquip unit.