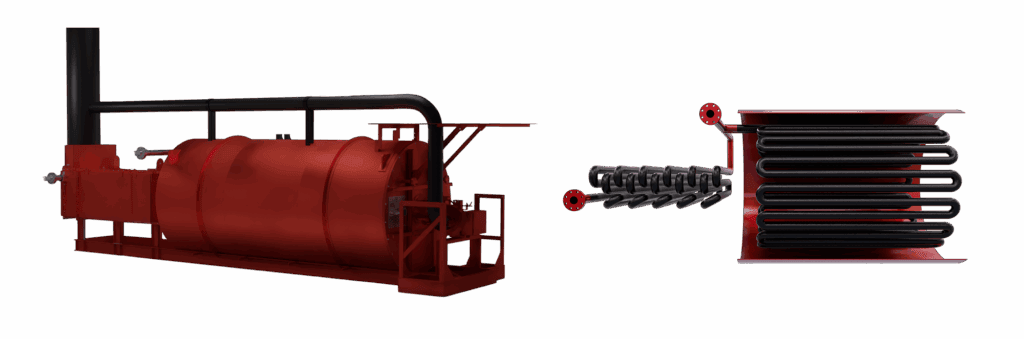

Low NOx Thermal Fluid Heaters

Enerquip designs low-NOx thermal fluid heaters to help facilities meet emissions limits without giving up efficiency, reliability, or performance. Whether you’re navigating air permits, tightening internal sustainability goals, or planning a new installation, our low-NOx designs make compliance simpler.

Standard Low NOx Design

Enerquip’s low NOx thermal fluid heaters come standard with the following features:

- Radiant heating coil: Serpentine

- Sizes: 1.3 to 40 MM BTU/Hr. Need something larger? Let’s talk.

- Emission options: Low NOx (<30 ppm with an upgraded burner and flue gas recirculation) or Ultra Low NOx (<9ppm with an ultra-low NOx mesh head burner)

- Burner: High-efficiency gas-fired burner with burner management system (BMS)

- Finned convection section: Built-in economizer recovers waste heat to improve efficiency by up to 10%

- Recirculation pump(s)

- Control panel: NEMA 4 panel with integrated safety features and alarms

- Fuel train: Pre-piped and pre-wired for natural gas and/or alternate fuels

- Expansion tank: 1,000-gallon

Optional add-ons or upgrades:

- Tank stand: Available upon request in various custom sizes

- Control panel: NEMA 4X, app connectivity for remote diagnostics

- Expansion tank: 250 to 3,000 gallons with optional nitrogen blanketing

Optional start-up support includes:

- Review of installed work and piping

- Supervision of system fill and oil circulation

- Burner tuning

- Testing of circuits and safety devices

- Operator training for monitoring and safe operation

- Troubleshooting as required

Why Serpentine Coils Support Low NOx Performance

Enerquip’s serpentine coil design plays a key role in reducing NOx while improving overall heater efficiency.

Large Combustion Volume – The spacing and layout of serpentine coils create a large radiant firebox. This lowers volumetric heat release and reduces overall firebox temperature — both of which help limit NOx formation.

Low Stack Temperature with an Integrated Economizer – Our built-in economizer cools flue gases to roughly 100°F above the incoming hot oil temperature. Lower flue gas temperatures entering the flue gas recovery system reduce flame temperature and further limit NOx during combustion.

Large Flue Gas Recirculation Duct – By placing the stack opposite the burner, Enerquip creates a longer flue gas recovery duct run. These ducts are often oversized to increase surface area, allowing recirculated gases to shed heat before returning to the burner. Cooler recirculated gas means lower flame temperatures and lower NOx output.

Pairing Low NOx Heaters with Steam Generators

Pairing a low NOx thermal fluid heater with an industrial steam generator enhances both efficiency and environmental sustainability. Instead of relying on a separate boiler, steam generators use heat from the thermal fluid system to produce steam, reducing fuel consumption and emissions with a single emissions source. This setup offers key benefits:

- Improved energy efficiency with reduced fuel consumption

- Lower overall emissions from indirect steam generation

- Reduced water usage and chemical treatment needs

- Longer equipment life with less scaling and corrosion

Curious how quickly a high-efficiency thermal fluid heater could pay for itself? Use our Serpentine Coil Thermal Fluid Heater ROI Calculator to estimate fuel savings and payback time.

Talk to an Emissions-Smart Heating Expert

Whether you’re budgeting, designing, or preparing for permitting, Enerquip is here to help. Contact us or request a quote to discuss low-NOx heater options for your application.