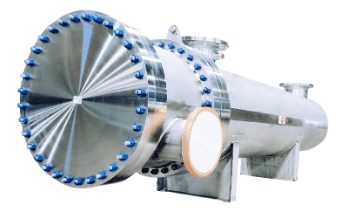

Industrial Shell & Tube Heat Exchangers

Whether you need shell and tube heat exchangers for multi-stage evaporation in an ethanol plant, condensing organics in a chemical plant, vaporizing LNG in a refinery, heating asphalt to ensure pliability, gas cooling in a landfill, or recycling plastic, Enerquip is the right source for dependable, high-quality shell and tube exchangers you can trust. Get started. Request a quote today.

Heating & Cooling Duties of Industrial Heat Exchangers

Enerquip’s full line of shell and tube heat exchangers perform the following heating and cooling duties:

- Vapor: to Vapor or Liquid

- Liquid: to Vapor or Liquid

- Hot Oil: to Asphalt, No. 6 Oil, No. 2 Oil, or Steam

- Steam: to Asphalt, No. 6 Oil, or No. 2 Oil

And come in a variety of standard and custom design configurations, including:

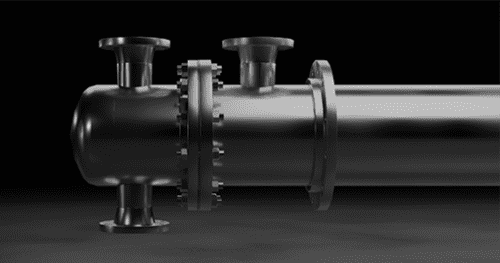

- Standard shell and tube

- Hairpin

- Tube-in-Tube

- Finned Tube

Corrosion Resistance

It’s important to determine your application’s most critical criteria when choosing the material for your heat exchanger. To allow for all types of applications and process fluid, Enerquip fabricates shell and tube heat exchangers from a wide variety of materials, including:

- Carbon steel

- 304L & 316L stainless steel

- Duplex stainless steel 2205 & 2507

- Hastelloy

- Alloy 20

- Monel 600

- AL-6XN

- Titanium Gr2

Features & Options

Enerquip listens to our customers and anticipates their special needs for operating and maintaining their shell and tube heat exchangers. We strive to minimize maintenance downtime, while providing safe features that help your maintenance team quickly and efficiently inspect, clean and service your exchangers.

We may suggest optional features such as:

- Davit arm or hinge assemblies for removing heavy bonnets

- Channel covers

- Insulation (non-asbestos and chloride free)

- Horizontal saddles or vertical mounting supports

- Vacuum breakers, sight glasses

- ANSI flanged, lapjoint, NPT threaded, or sanitary tri-clamp connections

- Jaygo clamps for frequent head removal

- Twisted tape turbulators for flow enhancement and improved heat transfer

- Floating tube sheets for thermal expansion protection

- Enhanced surface finishes, up to 15Ra Electropolished

Ensuring High-Purity Standards

To ensure the integrity of our sanitary and pharma-grade exchangers, and to help prevent any kind of cross contamination, our carbon and stainless products are manufactured in two different facilities. Our shop in Medford, WI, is a stainless-steel shop only. All carbon steel manufacturing takes in our Beggs, OK, shop.

Our experienced engineers can help you evaluate cost saving suggestions on higher alloy heat exchangers, like using explosion-bonded clad tube sheets and channel covers instead of solid plates, and using lap joint flanges where appropriate, instead of solid high alloy flanges.

Safety Code Compliance

You can be assured that Enerquip has your safety and the security of your facility in mind. All of our shell and tube heat exchangers are designed to TEMA C, B or R, following best practices for thermal design and construction.

We also evaluate every design using Compress codeware to ensure that your new exchanger will meet all of the safety requirements of ASME Code, and when requested, any nozzle loadings, seismic considerations and other site conditions that can affect the stability of your equipment. Every exchanger design is reviewed and approved by a 3rd party inspector, who also provides oversight during fabrication, and witnesses the ASME hydro-test of every exchanger.

Industrial Applications for Shell & Tube Heat Exchangers

As one of the most vital and widely used pieces of process equipment, every industrial process will likely involve some type of temperature regulation requiring a heat exchanger.

Industrial heat exchangers are used as components of air conditioning and cooling systems, heating systems, and are used for safe temperature regulation of machinery, chemicals, oil, water, gas, asphalt, and other substances in industrial plants.

Enerquip’s exchangers are also often used to capture and transfer steam or heat exhaust that is released as a byproduct of a process so that the steam or heat can be reused elsewhere. This process improves production efficiency, saving the industrial plant time, resources, and money.

Learn how to choose the best industrial heat exchanger for your facility.

Need a quote on a future project? Let’s talk! Give us a call today at (833) 516-6888 or contact us online to learn more about our efficient, American-made industrial heating systems.