Bayonet Immersion Heaters Designed for Maximum Efficiency

Unlike our shell and tube exchangers and suction heaters, which are designed to heat liquids as they are pumped through the exchanger, bayonet immersion heaters are designed to efficiently heat entire tanks of fluid. With our bayonet immersion heaters, the tube bundle is completely immersed in the tank, and the heating coil is directly exposed to the fluid for maximum heating efficiency.

Enerquip’s bayonet heaters are easy to install and take up no extra space. As immersion heaters, they’re inserted directly into the liquid through a tank flange, resulting in space and energy efficiency. Plus, with only a utility hookup needed for installation, you’ll save time and money on installation costs.

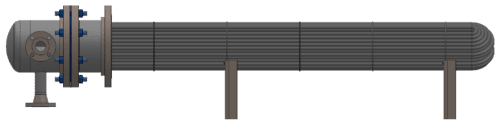

Our bayonet style tank heaters come equipped with a tubesheet, tube bundle, and a bonnet with utility connections. They’re easy to remove for cleaning and inspection, making maintenance a breeze. And, with pre-existing flanges and manways on your tank, installation is a snap.

Enerquip’s bayonet heaters are designed to withstand harsh operating conditions, including high temperatures, corrosive materials, and heavy-duty use. Our bayonet heaters are constructed from high-quality materials and are built to last, ensuring reliable and efficient heating.

Bare or Finned Tubes

Enerquip’s bayonet immersion heaters can be built with traditional bare tubes or with helically wound fins. When viscosity is not a concern, the fins create significantly more surface area resulting in greater heat transfer and efficiency.

Finned pipe bayonet heaters are commonly used in tank terminals, chemical processing, and oil and gas production. They are typically designed to operate at high temperatures and pressures, and can be customized to meet the specific needs of a particular application, including common ones below.

Bare Tube Bayonet Heater

Bayonet Heater Applications

Enerquip’s bayonet heaters are versatile and can be used in a wide range of applications that require efficient heating of tanks or vessels. Here are some examples of industries and processes where our bayonet heaters are commonly used:

Chemical Processing: Our bayonet heaters are widely used in chemical processing applications to heat liquids, such as acids, solvents, and other corrosive materials.

Oil & Gas: In the oil and gas industry, our bayonet heaters are used to heat storage tanks, pipeline transfer stations, and refineries.

Asphalt: Bayonet heaters are widely used in the asphalt industry for the heating of bitumen, which is a highly viscous, semi-solid form of petroleum.

Food & Beverage: Bayonet heaters are also used in the food and beverage industry to heat liquid products, such as dairy products, sauces, and beverages.

Pharmaceutical: In the pharmaceutical industry, our bayonet heaters are used to heat tanks containing various chemicals, including active ingredients, solvents, and other raw materials.

Water Treatment: Our bayonet heaters are used in water treatment applications to heat water or chemicals used in the treatment process.

Power Generation: Bayonet heaters are also used in power generation applications to heat water or steam used in power plants.

Whether you need to heat liquids in a small laboratory tank or in a large industrial vessel, Enerquip’s bayonet heaters provide efficient and reliable heating solutions for a wide range of applications. And because customization matters, our bayonet heaters can be built with carbon steel or 316L stainless steel.

Quality Solutions

Enerquip prides itself on providing quality and cost-effective solutions to its customers. Our bayonet heaters reflect these points as they are a practical way to heat nearly all types of liquid. All of our bayonet heaters are fabricated with carbon or stainless steel. For more corrosive applications, we work with a variety of stainless steels and higher alloys, ensuring long life for our equipment and your process.

In addition to our standard models, we can provide equipment customized to your specifications. Regardless of which option you choose, your equipment will arrive quickly and safely to your site.

All of our equipment is built according to industry standards. We will work with customers to make sure that the products they purchase meet the material and finish requirements needed by their particular industry.

Let’s talk about a solution for you. Request a quote, today.