Industrial heating systems provide the heat required for many industrial processes. These systems include thermal fluid heaters, asphalt heaters, low NOx heaters, waste heat economizers, and shell and tube heat exchangers. Each heater offers an ideal solution for specific applications.

Enerquip designs and manufactures 100% American-made industrial cooling, heating, and sanitary equipment, including thermal fluid heaters for various applications. Learn more about the features and benefits of each type of industrial heating solution we offer.

Enerquip Industrial Heaters

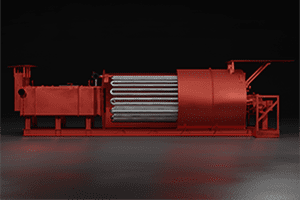

Serpentine Coil Thermal Fluid Heaters

Serpentine coil thermal fluid heaters are some of the most efficient and durable industrial heaters on the market. Some of the distinct properties of serpentine coil thermal fluid heaters include:

- Design: In the radiant section of the heater, heat is transferred to the front, sides and back of the serpentine coil. This allows for more even heat distribution, less fluid degradation, longer tube life, and higher operating oil temperatures.

- Efficiency: Serpentine coil heaters offer 10 to 15% more efficiency than helical coil heaters. A facility switching to a serpentine coil heater from a helical coil with a 2 MM Btu/hr max load can save up to $270,000 annually on fuel costs.

- Durability: Serpentine coil thermal fluid heaters enable longer thermal fluid life spans compared to other fluid heaters.

Helical Coil Heaters

Thermal fluid heaters with helically wound coils are constructed using a coil wound in a spiral shape. This design is frequently used in industrial heaters that are fueled by fire. For clients seeking a smaller size and reduced heat requirements, our helical coil systems provide a more affordable alternative, delivering approximately 85-90% of the efficiency of our serpentine coil technology.

Although their main purpose is to heat thermal oil, these heaters can also be employed to directly warm various fluids, including oil, asphalt, water, and mixed fuels.

Low NOx Heaters

Low NOx heaters are industrial heaters that can considerably reduce harmful gas emissions, such as nitrogen oxide (NOx). Their state-of-the-art combustion technology includes flue gas recirculation and premix burners to minimize harmful gas emissions.

Asphalt Heaters

Asphalt heaters use infrared heat to soften the asphalt without burning the tar oils, an integral component of the product’s flexibility. These specialized heaters can heat asphalt to original mixing temperatures in just 5 to 10 minutes. They are an efficient and economical method of heating asphalt for road and roofing applications.

Waste Heat Recovery Units

Waste heat economizers or waste heat recovery units capture heat energy to reuse it within the industrial heating system. They can capture heat from processes such as incineration or turbine operation, allowing the facility to cost-effectively reuse the heat in other heating applications. Economizers come affixed to our serpentine coil thermal fluid heaters, or can be stand alone equipment.

Shell and Tube Heat Exchangers

Shell and tube heat exchangers are a type of heat exchanger with an outer shell or pressure vessel with bundles of tubes inside. They are extremely versatile, and are commonly employed in high-pressure and high heat applications, large chemical processes, oil refineries, food and beverage, pharmaceutical applications, and more. As one fluid flows through the tubes, another process fluid flows through the shell around the tubes, transferring heat between the two media.

Industrial Heaters From Enerquip

With so many types of industrial heaters to choose from, it’s critical to select the right type for your specific application. Since 1985, Enerquip has been a trusted designer and manufacturer of industrial heating, cooling, and sanitary equipment. All of our solutions are designed and built in-house in our U.S. fab shops and offices. Contact us or request a quote to speak with a specialist about your industrial heating solution.