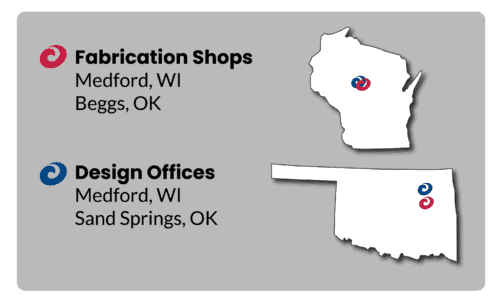

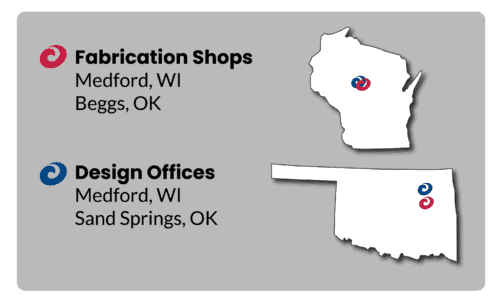

Enerquip has been a trusted provider of American-made sanitary and industrial heating and cooling solutions since 1985. Our equipment is proudly designed and built in the USA in our carbon-neutral fabrication shops in Medford, WI, and Beggs, OK, and design offices in Medford, WI, and Sand Springs, OK.

Enerquip’s Mission & Vision for the Future

OUR MISSION is to serve our partners and customers by providing high-impact thermal solutions that enable them to achieve their highest levels of efficiency, productivity, and success. We accomplish this by continuously innovating and delivering premium products and exceptional service that exceeds expectations.

OUR VISION is to lead the way in pioneering innovative thermal solutions, while building lifelong relationships, all anchored by our unwavering commitment to precision, integrity, and social responsibility.

Enerquip’s innovative line of products

While our thermal equipment is made right here in the United States, the impact of our equipment is far-reaching. We are proud to partner with manufacturers and facilities worldwide to provide efficient, state of the art thermal solutions, including shell & tube heat exchangers, vapor condensers, thermal fluid heaters with serpentine coil technology, helical coil heaters, tank heating coils, steam generators, economizers, suction heaters, bayonet heaters, and more.

Standard & customized solutions

Along with spare parts, we stock a variety of sanitary off-the-shelf heat exchangers that can fulfill many of our customer’s needs. When you have unique requirements, our expert designers deliver highly customized solutions based on your specific needs and requirements. Because our design and sales engineers have many years of combined heat transfer experience, Enerquip can offer the very latest in heating and cooling technology.

Enerquip’s approach to project management

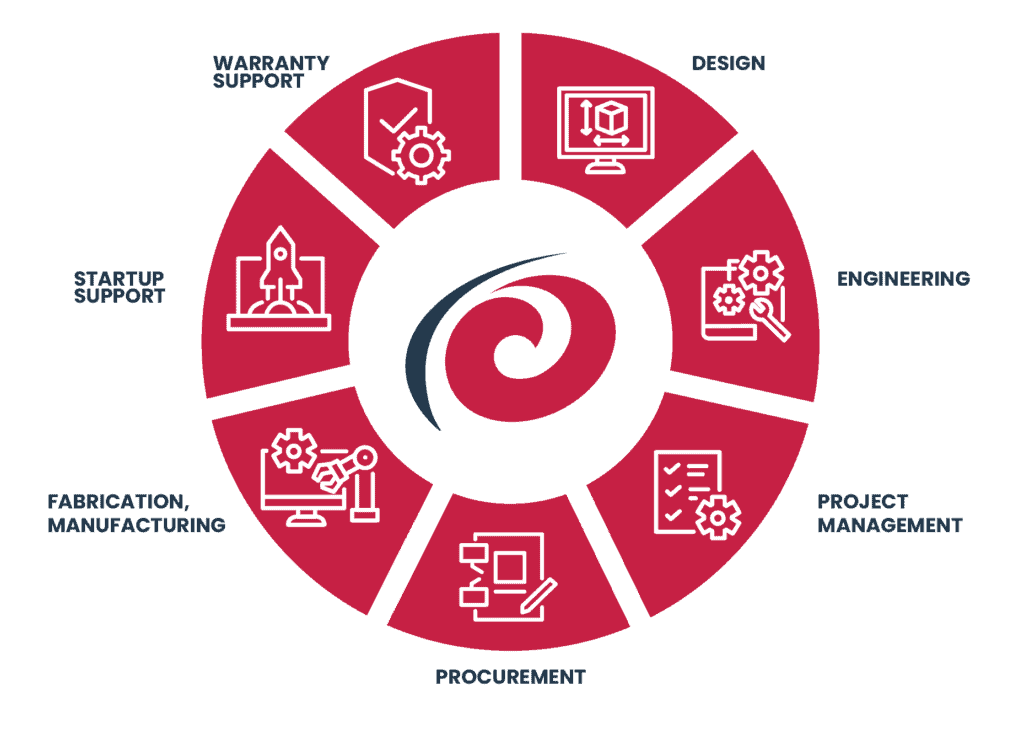

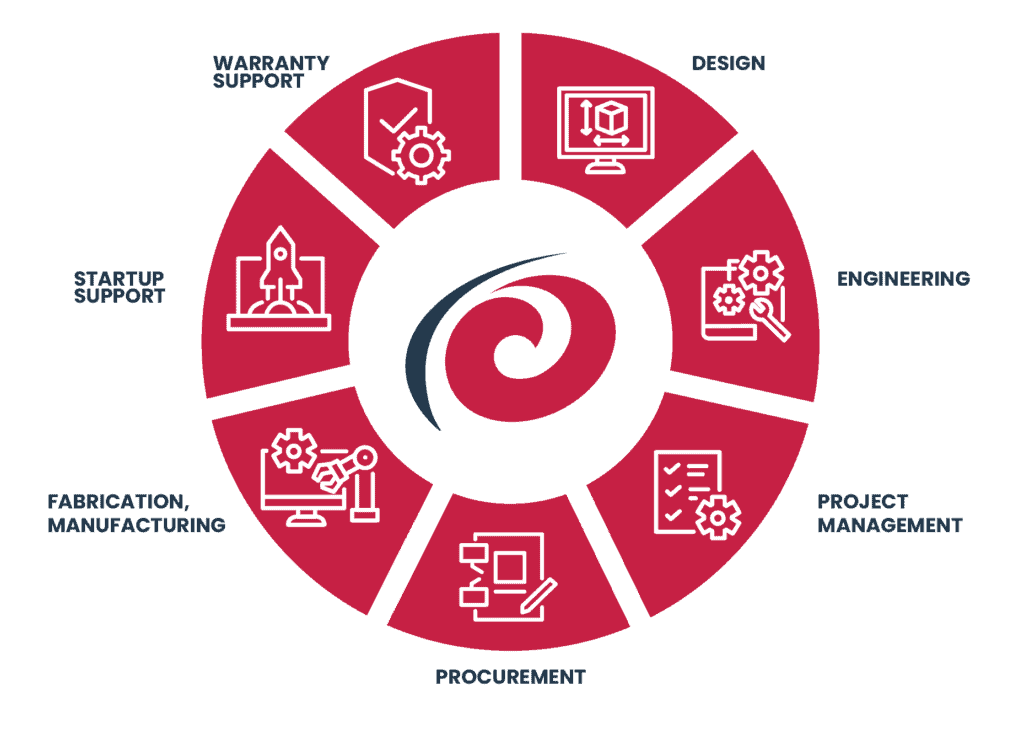

Enerquip takes a uniquely proactive approach to project management. From quoting through post delivery support, our customers experience a streamlined and consistent process with on-time delivery.

Our design expertise and quality standards provide customers with durable, low maintenance heating and cooling equipment and a return on investment that exceeds their expectations. Even under the toughest operating and regulatory conditions, customers have peace of mind knowing our products will meet their needs.

Industries we serve

Our reputation for custom, innovative designs, and high-quality fabrication, have earned us preferred supplier status with leading companies in a variety of markets, including pharmaceutical, food & beverage, dairy, cannabis, personal & pet care, chemical, asphalt, biodiesel & renewable energy, refining, tank terminal, commercial, and more. We design and manufacture for original equipment manufacturers (OEMs), resellers, distributors, representatives, and direct to end-users.

Our Customers Value These Enerquip Advantages

Expertise & Experience

Our team of committed experts and culture of innovation, combined with our quality standards, provides our customers peace of mind that our products will meet their needs, even under the toughest operating and regulatory conditions.

Learn More

Design & Fabrication Quality

In an age where “high quality” is expected as the norm for a preferred supplier of process equipment, Enerquip goes above and beyond what is expected and required, to exceed our customers’ expectations and regulatory standards.

Learn More

Project Management

Our detailed approach to project management includes frequent communication throughout the design, fabrication and testing of your product, and prevents roadblocks and streamlines the entire process, from engineering through delivery.

Learn More

Enhanced by our integrated capabilities, we craft top-tier equipment that not only mitigates risk but also boosts performance, reduces operational costs, and maximizes return on investment (ROI).

Our full circle approach, encompassing everything from design and engineering to fabrication and aftermarket support, ensures that every stage of the process is handled with expertise and precision. We provide comprehensive solutions tailored to meet our customer’s needs.

Enerquip's Culture

At Enerquip, our goal is not to be good — it’s to be extraordinary. Extraordinary performance comes from extraordinary people. And the foundation for extraordinary people is an extraordinary culture.

Enerquip’s 31 fundamentals define our unique culture. These fundamentals set us apart and make us leaders in our field. Enerquip’s fundamentals guide our journey to extraordinary, not only for our team and our customers, but also for our families and our communities.

We feel a social responsibility to care for and give back to the communities in which we work, live and play. We do this in the following ways.

Employee Match

Enerquip is committed to supporting and encouraging its employees to “lift others” through giving and servicing. Therefore, Enerquip provides gifts to organizations at 100% of the employee’s contribution up to $500 per employee per calendar year. This also includes employees’ volunteer hours at $10 per hour.

Community Giving

In addition to its employee giving programs, Enerquip donates funds directly to help further advance the work of area non-profits. Our community giving efforts focus on education, human needs, and civic and community needs.

Investment in our schools

Enerquip is committed to nurturing the physical and mental growth of local students. We proudly support area sports and school programs, and we make significant investments in high school tech-ed initiatives and scholarships for further education. Enerquip donates scrap metal to schools, offers tours, internships, and mentorship programs, and provides students with hands-on welding simulations at career fairs and other events.

Sustainability

At Enerquip, we prioritize sustainable manufacturing practices. Our efforts include using LED lighting, recycling stainless-steel shavings, coolant, oil, and tooling, and maintaining extensive outdoor green spaces to foster a healthier environment. We take pride in operating carbon-neutral manufacturing facilities in Medford, WI, and Beggs, OK.

Beyond our internal initiatives, Enerquip’s equipment enhances energy efficiency and optimizes heat transfer across various industries, including renewable fuels. Our reboilers, evaporators, preheaters, and condensers have long served the ethanol and biofuel sectors. More recently, our thermal solutions have been instrumental in landfill gas and plastics recycling through pyrolysis processes.

♻️ Learn more about Enerquip’s commitment to sustainability.

Enerquip's History

In the early 70s, a couple of former employees from the Ingalls Shipbuilding Company came to Medford with a military contract to provide heat boilers skids for 90 naval destroyers. This was the beginning of Conseco (later Enerquip).

Conseco built boilers and industrial heat exchangers for government contracts and dabbled in nuclear projects. These contracts included the heating and cooling equipment on the Spruance Kidd-class guided missile destroyers. The boilers had many applications, including producing domestic hot water for the ship, lubricating the main engine, and cooling wastewater from gas turbines.

During the decade that followed, orders from the Navy were sporadic. While Conseco attempted to diversify and expand into the private sector, Conseco’s business was on shaky ground by the early 1980s.

In 1985, a team of Medford, WI, business leaders purchased Conseco out of bankruptcy. These men included Pep Simek, owner of Tombstone Pizza, Ron Simek, Dewey Sebold, and Tom LaBarge. Conseco then changed its name to Enerquip.

In the early years, Enerquip continued providing heat recovery equipment to the military and private sectors.

One of its many product offerings was building actuator bases. A spotlight project was the Three Gorges Dam in China. After a large customer in this space went out of business, Enerquip left the actuator base business behind. Enerquip also saw the turbulence from government contracts, so they decided to pave a new path forward.

Though they were moving through new and uncharted waters, Enerquip chose to put all its efforts into heat exchangers. It was the right path that led to steady growth.

Changing Ownership & Management (Late 1980s)

By the late ’80s, Ron Simek, Dewey Sebold, and Tom LaBarge sold their shares of Enerquip. Pep Simek continued as an investor, while new partner John Holroyd took over management of the daily operation. John had a background in purchasing sanitary equipment and various ground-breaking engineering advancements in the pharmaceutical and medical industries.

In the early 1990s, Holroyd led the company into the stainless steel heat exchanger market.

A couple of Enerquip’s first key partnerships were with Ecolab and Sani-Matic. Enerquip updated Sani-Matic’s shell and tube heat exchanger design from a straight tube to U-tube. The efficiency and quality of the units moved Enerquip onto its preferred supplier list.

Around the same time, Enerquip was able to help a dairy in the Midwest save dozens of milk tanks that were about to go to waste. With some quick design and fabrication work, Enerquip was able to get a replacement unit to them on the same day. This act gave Enerquip a name in the dairy industry.

Today, if you look across Wisconsin, you’ll be hard-pressed to find a dairy without an Enerquip product providing the valuable heat exchange.

In the mid-90s, the 3-A Sanitary Standards were established and played a significant role in the transition to stainless process equipment.

As time went on, Enerquip expanded its market share into food, beverage, and pharmaceuticals.

Enerquip Launches Representative Network

With Enerquip gaining market share in the sanitary markets, it grabbed the attention of different distributors. Reid Kapton was the first. This partnership set the stage for all future successful representative and distributor partnerships.

Efficiency & Quality Take Center Stage

In 1995, current President & CEO Jeannie Deml joined the team as Administrative Assistant to Holroyd and the sales team. A considerable portion of her role was understanding customers’ needs, developing streamlined processes, and creating efficiencies. This early work set the framework for her future advancement.

Enerquip knew growth was essential. One way to do this was to reduce the time it took to build a heat exchanger. In just a few short years, Enerquip cut its production time in half, leading to decreased customer lead times. In addition, the team wanted the Enerquip name to stand for quality, durability, and longevity. Every piece of equipment leaving the shop was a badge of honor for the team. Since that point, Enerquip has become known for its quality equipment.

Over the next several years, Enerquip focused on building efficiencies, inter-department communication, and teamwork. As a result, Enerquip began building stock units for immediate shipment. This now offered better internal efficiency and shorter lead times for customers. It was a win-win.

Technological growth was seen around the world in the 90s, and Enerquip was no different. The decade brought the following advancements to Enerquip:

- Thermal calculations were now being computed with B-JAC software, including TEMA stress testing.

- Enerquip began roller expanding its heat exchanger tubes to the tube sheet.

- By 1996, Enerquip added 6”, 8”, and 10” stock units in lengths of 48” and 84”. These additions offered fast shipments that now fit most water-to-steam applications for the dairy industry.

- In the fall of 1996, Enerquip’s personal computers moved to Windows networked workstations.

- Enerquip created Excel and Visual Basic Application (VBA) software to size heat exchangers in-house.

- Enerquip designed its first industrial strength heat exchanger to produce artificial snow for a Colorado ski resort.

- In 1997, Enerquip exhibited at its first tradeshow, InterBev. This was the first of many.

- In 1998, Enerquip sent its first email. As with most technology, that changed the face of the business forever.

In 1999, Holroyd purchased a small electropolish business to bring more production in-house. Electropolishing is a process of removing a layer of metal to reduce surface roughness. It’s often required in pharmaceutical and other sanitary applications.

When Holroyd moved to southern Wisconsin to focus his attention on this new venture, Deml became General Manager of Enerquip.

In the early 2000s, Enerquip Electropolish developed a process to recycle its acid solutions to create a more sustainable business process. To help expand its product offering, Enerquip Electropolish moved into a larger building where it could take on more significant parts and larger quantities.

In 2005, a small portion of the electropolishing process came in-house at Enerquip Heat Exchangers. For the first time, Enerquip in Medford, WI, could electropolish its own product, saving valuable time and resources.

With electropolishing now in-house, Enerquip Electropolish was sold in 2006.

“We owe a lot to John and Pep; they persevered all those years. I think many people would have given up, but they didn’t,” says Deml when talking about how grateful Enerquip is to Simek and Holroyd and their significant role in leading Enerquip down the path to success.

Engineer Tom Fitzsimmons was familiar with Enerquip’s quality and hardworking culture since the early 2000s. In 2007, after buying a heat exchanger for the ice arena in Cody, WY, he discovered that the owners, Simek and Holroyd, were looking to sell the company. Fitzsimmons discussed this opportunity with his local colleague and private investor, James Nielson. In August 2008, Nielson purchased Enerquip.

James Nielson then added Jay Nielson, Tom Fitzsimmons, and Bill War to Enerquip’s board of directors. Kirk Novak was named President & CEO of Enerquip.

While Enerquip’s core business remained the same, it began a more intense pursuit into the pharmaceutical market.

In 2011, long-time employee and General Manager Jeannie Deml was named President & CEO of Enerquip.

Emergence Into New Markets

By 2012, Enerquip expanded its product offering into the chemical, commercial, refining, biofuels, and personal care markets.

Then in 2015, began building sanitary equipment for the brewing industry, followed by cannabis, aerospace, and pet care.

With the facility in much-needed repair, in August of 2014, a remodeling and expansion project began.

The renovation goal was to enhance the work environment in the offices and manufacturing plant while setting the company on a path to future growth. The renovation included:

- 37 upgraded office spaces

- Windows that provide natural light

- Two storage towers that allowed Enerquip to save much-needed manufacturing space. One tower is 22 feet tall, and the other is 56 feet tall with a storage capacity that can hold 200 tons of material.

In January 2015, the team moved into its newly expanded office and shop space.

Thinking to the future, in 2018, Enerquip purchased the lot just north of the plant, along with a home on the northwest corner of Allman Ave and 2nd Street.

Enerquip’s growth continued in the spring of 2021 when it purchased American Heating Company (AHC).

American Heating Company manufactured its products out of Beggs, OK, by a small but dedicated team. Its main products were industrial heaters, economizers, steam generators, and tank heating solutions. A leader in the industrial heating space, you could find American Heating Company industrial heaters in large and small tank terminals and asphalt processes across the country. The acquisition was a match made in heaven with its strong product line and wonderful, hardworking staff.

In the summer of 2022, Enerquip and American Heating Company moved forward together as Enerquip Thermal Solutions. At that time, Enerquip launched a new joint website.

Our Team Today

Enerquip has approximately 65 employees and a network of over two dozen representatives and distributors located across North America. Presently Enerquip runs one shift on its production floors in Medford, WI, and Beggs, OK.

While our growth goals are aggressive, we endorse controlled growth to meet our customer’s needs and provide our team with the tools and training needed to be successful in competing on a larger scale.

We are excited about our growth and the new opportunities coming our way daily. We are fortunate to have a board of directors who support our vision and efforts and are willing to invest in Enerquip.

We firmly believe the key to continued success is providing the tools, equipment, and training necessary to further develop and empower our Enerquip team. The future is bright for Enerquip and filled with opportunities for those with the desire to succeed.

Ownership of Enerquip

Enerquip is fortunate to have a committed board of directors guiding our company since 2007. Under the leadership of Jay Nielson, majority owner and son of former owner Jim Nielson, each member brings extensive expertise in industrial engineering and management. Their unwavering support for our vision, coupled with strategic investments, drives our ongoing growth and success.

Enerquip’s Board of Directors (2007 – Today): Jay Nielson, Tom Fitzsimmons, Bill War

Jim Nielson, owner of Enerquip from 2007 to 2022, was born in Canada but made Cody, WY, his home at a young age when his family purchased Park Refining Company, later known as Husky Oil. After graduating from Cody High School and attending the University of Wyoming, he served as a commissioned officer in the U.S. Navy.

In 1973, Jim became President and CEO of Husky Oil, overseeing its growth into a major energy company. Following the company’s acquisition, he founded JN Oil and Gas in Billings, Montana. Later, he established Nielson & Associates in Cody, allowing more time for family activities.

Jim served on numerous boards and supported various philanthropic causes, demonstrating his love for the Cody community and Wyoming. He passed away at his home on November 17, 2022, at the age of 91.

Joseph (Pep) and Frances Simek moved to Medford from Chicago in 1960. By 1962 they were running the Tombstone Tap, a tavern located next to a cemetery, along with Pep’s brother, Ronald. The brothers came up with the pizza-making idea to bring in more money to support their families. They worked out of the bar’s 6-by-6-foot kitchen.

The pizzas were fine, but they got better after Pep broke his leg and, unable to tend bar, had time to fiddle with the recipe. He called the owner of a favorite Chicago pizza place, who told him, “the secret was in the spices.” The resulting pizzas were a hit, and within three years, Tombstone Pizza was available in the Medford area, selling 2,000 pizzas a day and known for the tagline, “What do you want on your Tombstone?”

The influence of their family remained in Medford for years.

The company was sold to Kraft in 1986 and eventually to Nestlé. Later Pep established Pep’s Pizza in Medford and had numerous other business interests, including the Embassy Suites/Regency Suites Hotel of Green Bay, Paradise Shores Hotel and Resort in Lake Holcombe, Captain Morgan’s Retreat in Belize, Enerquip Heat Exchangers, and so many others.

With her husband’s encouragement, Frances became a significant supporter of civic projects, settling a discussion about a new library by donating $1 million to build it in 1998. One night out of the clear blue sky, she called the mayor and told him that the argument about the library was over. She was building it.

The Simeks were generous to the community in many ways, often downplaying their role.

Joseph “Pep” Simek, Sr. passed away on February 18, 2013; Frances preceded him in death on November 1, 2010. They are survived by two sons Joseph, Jr. and Richard, a daughter, Lauren, four grandchildren, and six great-grandchildren.