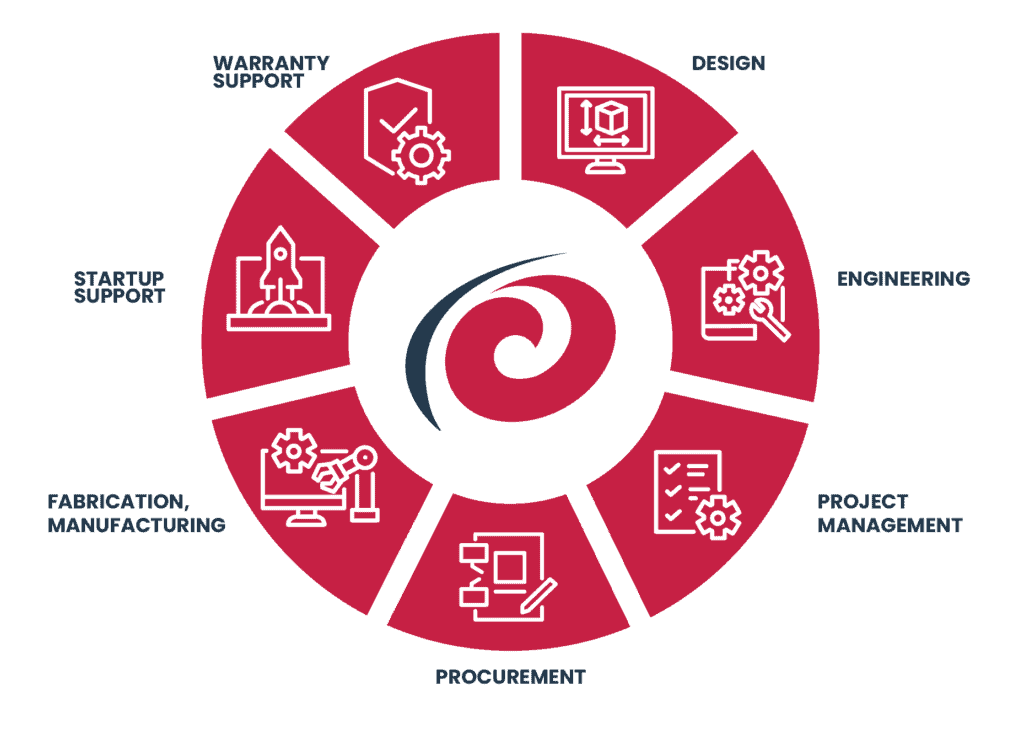

Enerquip’s Proven Process

Our experts and engineers have spent decades challenging and refining our process, earning Enerquip a reputation for innovative design, efficient manufacturing, excellent quality, and outstanding customer service.

We do more than just sell equipment; we work with you to plan current and future needs. Want us to review your current setup and provide a detailed plan? We do that, too.

At Enerquip, we work with professional engineering firms and top companies in our served industries. This collaboration has helped us develop a detailed approach to project management, ensuring frequent communication throughout the design, fabrication, and testing of your equipment. From engineering through delivery, you can rely on our streamlined process below.

Milestone Schedules

For larger or more complex projects, we’ll map out a detailed milestone schedule covering design, procurement, machining, fabrication, and testing.

-

Start and finish dates for each stage

-

Planned ship date you can count on

-

Weekly internal reviews on high-profile projects

-

Bi-weekly progress reports with photos through final inspections

Why you’ll like this: You always know where your project stands. No surprises—just clear communication and confidence in on-time delivery.

Step 1: Design Process

We start with a kickoff meeting to review your data sheets and ensure thermal designs comply with ASME Code.

-

ASME Code & seismic/nozzle calculations run in Compress software

-

General arrangement drawings delivered in 5–10 business days

-

Virtual design reviews confirm nozzle and support locations

Why you’ll like this: Fewer surprises later and a design tailored to your needs.

Step 2: Sourcing Plan

After design approval, our engineers issue a final bill of materials.

-

Reliable supplier network for raw materials & outsourcing

-

Common components used to shorten lead times

-

Long-lead items (burners, pumps, special alloys) flagged early

Why you’ll like this: Transparent lead times and fewer project delays.

Step 3: Quality Plan

We follow ASME Section VIII, Division 1 standards. Every step includes:

-

Material traceability

-

Certified weld procedures & inspections

-

Hydro-testing protocols

-

Factory Acceptance Test (FAT) coordination with you

Why you’ll like this: Confidence that your equipment is safe, compliant, and built to last.

Step 4: Fabrication Plan

Your project moves into production based on lead times:

-

Off-the-shelf equipment: Next-day shipment

-

Heat exchangers/tank coils: 8–12 weeks

-

Large systems: 18–22 weeks

Why you’ll like this: A predictable schedule that keeps your operations moving.

Step 5: Factory Acceptance Test

When required, we create an Inspection & Test Plan. For exchangers, this includes:

-

Verifying dimensions, nozzle locations, supports

-

Reviewing documentation, specs, and data sheets

-

Hydro-testing (witnessed by an authorized third-party inspector and, if desired, by you)

Why you’ll like this: Independent verification your equipment matches expectations before it ships.

Step 6: Start-Up Support

Every unit ships with installation instructions plus free support by phone, email, or web conference.

-

Optional on-site support and troubleshooting available for hot oil & asphalt heaters

-

Passivation options for stainless steel exchangers for extra corrosion resistance

Why you’ll like this: A smooth start-up and long-term reliability.

Step 7: Shipping & Documentation

-

Secure packaging (palletized or crated for global shipments)

-

Transit within the U.S.: ~3 days

-

ISPM-15 compliant crating for ocean/air freight

-

Final documentation package scanned, cataloged, and delivered within 1–2 weeks

Why you’ll like this: No stress about logistics—your equipment arrives safe, with paperwork in hand.

Ready to Get Started?

Partner with Enerquip for a proven process that delivers equipment on time, built to spec, and backed by expert support. Get started today – request a quote.