Heat exchangers are used to process heat exchange between different fluids at different temperatures. Heat exchangers are commonly found in refrigeration, HVAC units, wastewater plants, and in process manufacturing. Some industries have high sanitary standards and require equipment that maintains these standards. This is common in the pharmaceutical, food, beverage, and dairy industries. For these sensitive fluids, sanitary heat exchangers are required.

Types of Shell and Tube Heat Exchangers

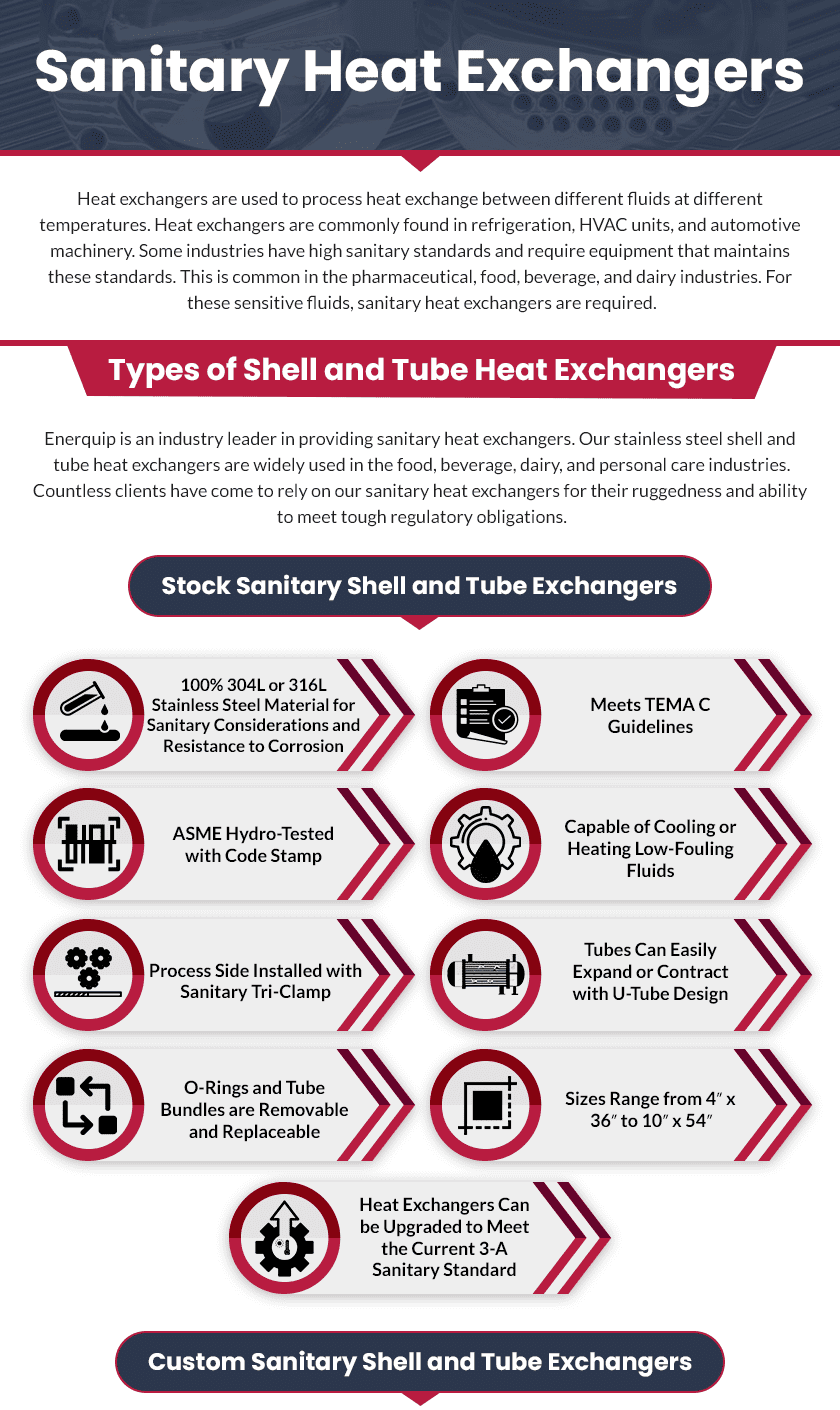

Enerquip is an industry leader in providing sanitary heat exchangers. Our stainless steel shell and tube heat exchangers are widely used in the food, beverage, dairy, and personal care industries. Countless clients have come to rely on our sanitary heat exchangers for their ruggedness and ability to meet tough regulatory obligations.

We can provide stock and custom sanitary shell and tube heat exchangers.

Stock Sanitary Shell and Tube Exchangers

- 100% 304L or 316L stainless steel material for sanitary considerations and resistance to corrosion

- Built to TEMA Class C

- ASME hydro-tested with code stamp

- Capable of cooling or heating low-fouling fluids

- Process side installed with sanitary tri-clamp connections for easy installation

- Tubes can easily expand or contract with U-tube design

- O-rings and tube bundles are removable and replaceable

- Sizes range from 4″ x 36″ to 10″ x 54″

- Heat exchangers can be upgraded to meet the current 3-A Sanitary Standard

Custom Sanitary Shell and Tube Exchangers

- Insulation free of chloride and asbestos

- Choice of vertical mounting supports or horizontal saddles

- Sight glasses, vacuum breakers

- Choice of ASME flanged connections, NPT threaded, or Sanitary Tri-clamp

- Option for upgrades to double tube sheet design or 3-A for high purity demands

- Expansion joints or floating tube sheets to aid in thermal expansion protection

- Passivation and electropolished product contact surfaces

- Davit arms (commonly used with heavy bonnet designs)

Design Requirements for Sanitary Heat Exchanger

Depending on the industry and application, design specifications may have special requirements.

Common requirements for sanitary heat exchangers include:

- Seal welding of tube-to-tube sheet joints

- Sanitary tri-clamp fittings

- Polished surfaces

- Manufactured to meet 3-A Sanitary Standard

- PTFE, Viton©, Gylon, or other gasket materials

- Clean-in-place design

- ASME BPE compliant

- ASME BPE sanitary fittings

Applications of Sanitary Heat Exchangers

Sanitary heat exchangers are commonly found in the food, beverage, pharmaceutical, and dairy industries. In most of these industries, a sanitary heat exchanger can eliminate or greatly reduce the amount of microbial activity. This process keeps goods safe, reduces the risk of spoilage, and meets regulatory requirements.

Sanitary heat exchangers can be used at various stages of production, including processing, filling, drying, and concentration. Heat exchangers can be used on products of varying viscosities, making them a versatile solution for temperature control.

Common industry applications of sanitary shell and tube heat exchangers include:

- Refrigeration

- Power plants

- Heating and air conditioning systems

- Food processing systems

- Chemical processing systems

- Pharmaceuticals manufacturing

- Waste heat recovery units

Common process applications that use shell and tube exchangers include:

- Cheese and milk pasteurization

- Beer cooling and beer wort heating

- Beverage pasteurization

- Ultra-high temperature sterilization

- Standard and pulpy juice pasteurization

- Bottled water treatment

- Liquid egg processing

- Ketchup and mustard cooling and heating

- Heating of starches, soups, and sauces

Benefits/Advantages of Sanitary Shell and Tube Heat Exchangers

Shell and Tube heat exchangers come in different forms that can be customized. Their ability to fit in countless sizes and configurations makes them a versatile solution. Adaptability makes shell and tube heat exchangers suitable for a wide range of applications. No matter the shape or size, they all provide three key benefits.

First is having a small spatial footprint. Not only does this free up space on the production floor, but it also reduces the risk of heat pockets that can damage other electrical components. Another great advantage is their minimal environmental impact. To remain effective, heat exchangers must run continuously to prevent overheating of control panels. As heat exchangers don’t rely on additional equipment to operate, they use less energy than other temperature control methods.

Lastly, shell and tube heat exchangers have lower operating costs than other options. Due to the reduced need for extra equipment, heat exchangers are inherently cheaper to maintain and operate.

The benefits don’t end there. Additional advantages of using a sanitary shell and tube heat exchanger include:

- Processing of fiber or particulate products

- High working pressure

- High working temperatures

- Simple inspection and disassembly

- High security in aseptic processes

- Easy to customize

Capabilities of Enerquip's Sanitary Shell and Tube Heat Exchangers

Enerquip has been in the business of sanitary and industrial heat exchangers since 1985. All of our equipment is fabricated in the US, minimizing the worry of unreliable overseas supply chains. While our production is stateside, we have fostered clients around the world due to our high standards of quality.

TEMA Standards

When it comes to sanitary shell and tube heat exchangers, we pride ourselves on meeting the standards established by the Tubular Exchanger Manufacturers Association (TEMA). This includes all the steps involved in manufacturing and testing. The TEMA standards allow our products to provide excellent consistency and long-term reliability. Specifically, our heat exchangers meet TEMA classes B, C, and R depending on application and customization.

3-A Sanitary Standard

We are one of the few sanitary shell and tube heat exchanger manufacturers who are certified to build heat exchangers that meet the 3-A Sanitary Standard. This allows us to work with food and dairy clients that most manufacturers can’t. We regularly work with 3-A inspectors to ensure that all of our designs and fabrication practices meet 3-A Sanitary Standards. When we provide clients with a sanitary heat exchanger, they can expect it to pass sanitary inspections without any deficiencies.

Clean-in-Place

Our commitment to excellence has allowed us to become a leading supplier of Clean-in-Place sanitary shell and tube heat exchangers in the US. We understand that many clients need a sanitary heat exchanger fast, and that’s why we offer off-the-shelf products. Our off-the-shelf products are available in a variety of sizes allowing for greater compatibility. When needed, we can utilize our thermal modeling software to make sure an application will work with our stocked products.

If stock units don’t meet your process needs, we have a dedicated team of engineers and designers when custom solutions are needed. We can take a consultative approach with clients to ensure that their sanitary heat exchanger needs are fully met.

Additional Upgrades

We can also provide the following upgrades to existing sanitary shell and tube heat exchangers.

- Cladding and insulation with stainless steel jacket

- Mounting saddle supports

- Connection and baffle changes in liquid applications

- Upgrades to meet the 3-A Sanitary Standard

- Passivation or electro-polished contact surfaces

- Material upgrades (Duplex, Hastelloy, 316L SS, AL6XN, and other alloys)

- Multiple pass designs

- Bonnets for a better tube side velocity in tight spaces

Work With Enerquip Today

If you have any questions about our capabilities, feel free to contact us anytime. Already have a project in mind? Request a Quote today.