High Purity Design and Fabrication

Enerquip is a leading supplier of pharmaceutical-grade stainless steel shell and tube heat exchangers. Our experts understand the quality and precision needed to help our customers perform their life-saving work. We take our role in this process seriously, demonstrated by the highest level of craftsmanship, rigorous in-process inspections and testing and full traceability of our materials.

For decades, we’ve been providing solutions for applications with the toughest operating and regulatory requirements. Leading Clean-in-Place (CIP) and Water-for-Injection (WFI) suppliers across the world have not only been impressed with our quality, but have standardized on Enerquip’s heat exchangers for their systems.

Enerquip’s resourceful team is here to provide you with sizing and design selection assistance. Our skilled sales engineers use state-of-the-art modeling software to recommend the right heat exchanger for each heating or cooling application.

Commitment to High-Purity and Safety Standards

Enerquip’s heat exchangers are engineered to meet rigorous sanitary and safety requirements, ensuring the highest quality processing standards:

- Built to ASME-BPE for safe product processing. Our engineers participate in ASME-BPE committee meetings to ensure that our talented craftsmen are leading the industry in hygienic design and fabrication.

- ASME Boiler and Pressure Vessel Code compliance

- Designed for easy disassembly, inspection, and maintenance

- Pharma-grade finishes (25Ra or better)

- Customizable styles, orientations, and upgrades to fit your specific process requirements

Read about five important qualities to look for in pharmaceutical process equipment.

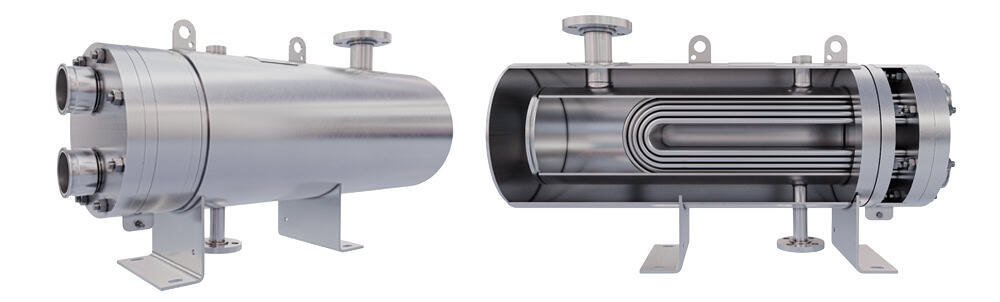

Shell & Tube Heat Exchanger Design: Pharmaceutical-Grade

Our pharmaceutical-grade heat exchangers are designed with a range of premium upgrades as standard.

Standard Pharma-Grade Design

- 316L stainless steel tube side material

- Seamless tubes polished to 25Ra

- 40Ra exterior finish

- Tube-to-tube sheet seal-welding

- Double tube sheet: aids in preventing cross-contamination of process fluids between the shell and tubes, and allows for easy leak detection.

- Fully radiused and polished return pockets and weep slots to enhance cleanability and draining.

- Pitched to promote draining: due to surface tension in highly polished tubes, customer-supplied air or heat may be required to fully drain exchangers

- Passivation of product surfaces

We also offer a range of advanced features that are commonly preferred by our pharmaceutical customers, as outlined below.

Optional Upgrades

- 15Ra Electropolish

- Insulation jacket: Thurmalox moisture barrier, covered with non-asbestos, chloride free Inswool ceramic insulation material

- Sight glasses (utility side)

- Level gauge ports

- Condensate collection sumps/chambers

- Nozzle covers: tack welded stainless sheet or PipeTite boots

Enerquip Pharmaceutical-Grade Shell and Tube Heat Exchanger

Heat Exchanger Applications for Pharmaceutical Processes

From product processing to cleaning systems, our shell and tube exchangers provide the flexibility, efficiency, and hygiene needed for high-purity operations. Below are some key applications where our exchangers excel in supporting pharmaceutical processes.

Product Heating and Cooling

In pharma manufacturing, keeping product temperatures consistent is key to ensuring uniform blending. Enerquip’s shell and tube heat exchangers provide reliable heating and cooling for both small and large batches. Their polished stainless steel surfaces prevent build-up and are easy to clean. These exchangers can also handle viscous products and allow easy surface verification via borescopes.

Designed to handle extreme temperatures, high pressures, and even vacuum conditions, they come in different configurations and can be customized for your space and needs.

Clean-in-Place Heating

Pharmaceutical facilities often rely on Clean-in-Place (CIP) systems to meet strict sanitation standards, allowing them to clean equipment without disassembly. These systems help prevent cross-contamination, fouling, and reactions. Enerquip shell and tube exchangers are used to heat the cleaning solution, typically steam or hot water, to the required temperature. The CIP process involves several steps: an initial rinse, circulating the cleaning solution for a thorough clean, and a final rinse. CIP systems not only save water and reduce labor but also allow the plant to continue operating while cleaning is underway.

Water for Injection (WFI) Heating & Cooling

Maintaining the purity of Water for Injection (WFI) is critical in pharma manufacturing. WFI is used for products like IVs and injections and must meet strict standards for chemical composition and bacterial endotoxins. Enerquip’s heat exchangers help maintain the right temperature during both storage and recirculation, ensuring WFI stays uncontaminated. Whether it’s distillation or reverse osmosis, our exchangers help manage WFI safely, preventing microbial growth and contamination with their smooth, polished surfaces.

Point of Use (POU) Cooling

In the pharmaceutical industry, point-of-use water coolers are used to deliver chilled water for various applications such as cooling equipment, cooling products, and maintaining the temperature of sensitive materials.

Vapor Condensing

Vapor condensers in the pharmaceutical industry are often used with their reactors to capture moisture that could be unsafe for the atmosphere.

Clean Steam Generation

We offer both sanitary and industrial steam generation solutions.

For sanitary and high-purity applications, steam is generated on the tube side of the exchanger, ensuring a hygienic process that is easier to clean and control compared to the shell side. The pure steam produced is ideal for various sanitary processes, including equipment cleaning. In this setup, pure water enters the bottom of the exchanger, where it is heated as it rises through the tubes, while hot oil, plant steam, or waste exhaust streams flow on the shell side.

Why Choose Enerquip for Your Pharma-Grade Processing Needs?

Enerquip combines decades of engineering expertise with a customer-first approach to deliver heat exchangers that are efficient, reliable, and tailored to your requirements. Our knowledgeable sales engineers are here to guide you through every step, from research to purchase.

Ready to get started? Contact an Enerquip Sales Engineer today to explore how our solutions can optimize your pharmaceutical processes.

Learn more about the many benefits of incorporating shell-and-tube heat exchangers into your operation. Whether you’re exploring options or ready to make a decision, we’re here to help.