High Efficiency Thermal Fluid Steam Generators from Enerquip

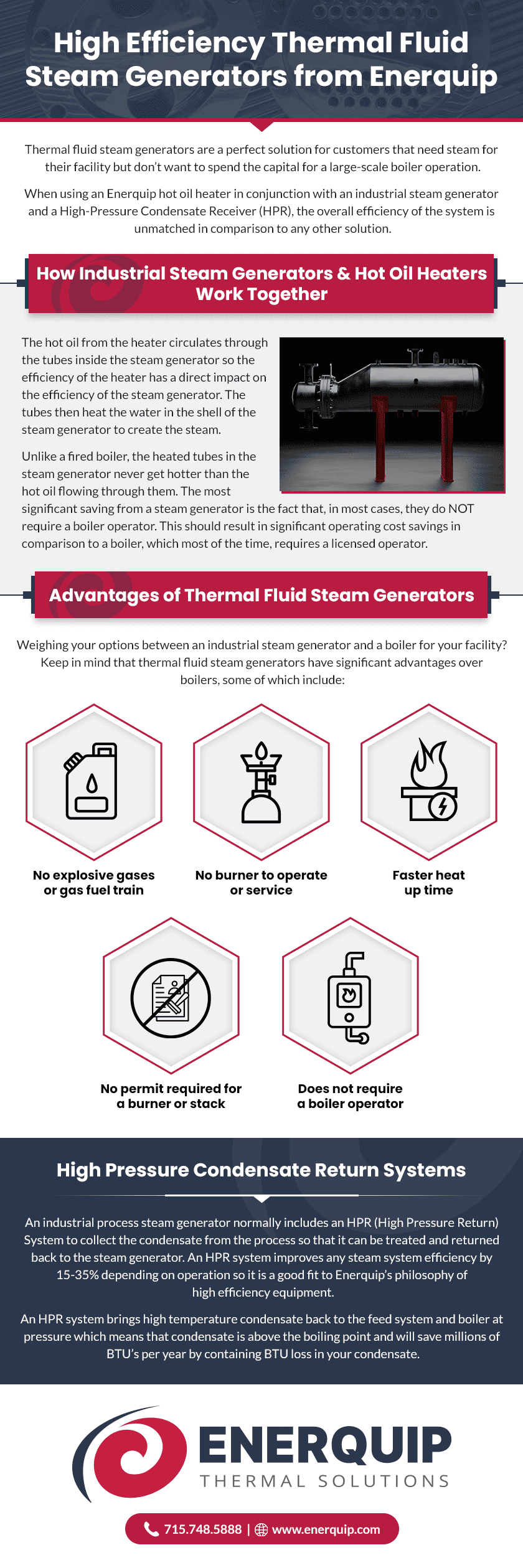

Thermal fluid steam generators are a perfect solution for customers that need steam for their facility but don’t want to spend the capital for a large-scale boiler operation.

When using an Enerquip hot oil heater in conjunction with an industrial steam generator and a High-Pressure Condensate Receiver (HPR), the overall efficiency of the system is unmatched in comparison to any other solution.

How Steam Generators & Hot Oil Heaters Work Together

The hot oil from the heater circulates through the tubes inside the steam generator so the efficiency of the heater has a direct impact on the efficiency of the steam generator. The tubes then heat the water in the shell of the steam generator to create the steam.

Unlike a fired boiler, the heated tubes in the steam generator never get hotter than the hot oil flowing through them. The most significant saving from a steam generator is the fact that, in most cases, they do NOT require a boiler operator. This should result in significant operating cost savings in comparison to a boiler, which most of the time, requires a licensed operator.

Advantages of Thermal Fluid Steam Generators over Boilers

Weighing your options between an industrial steam generator and a boiler for your facility? Keep in mind that thermal fluid steam generators have significant advantages over boilers, some of which include:

Higher Safety: Thermal fluid steam generators operate at lower pressures compared to boilers, reducing the risk of explosions and other safety hazards associated with high-pressure steam boilers.

Improved Efficiency: Thermal fluid steam generators typically have higher thermal efficiency compared to traditional boilers. They use a closed-loop system where the thermal fluid is heated and circulated, resulting in better heat transfer and reduced energy losses.

More Precise Temperature Control: Thermal fluid steam generators provide precise temperature control, allowing for consistent and accurate heating. This is especially important in applications where maintaining a specific temperature is critical, such as in certain industrial processes.

Compact Design: Thermal fluid steam generators are often more compact and require less space compared to boilers. This can be advantageous in installations where space is limited.

Versatility: Thermal fluid steam generators can use a variety of heat sources, including natural gas, diesel, biomass, and waste heat recovery. This versatility allows for more flexibility in choosing the most suitable and cost-effective fuel source for a specific application.

Reduced Maintenance: Thermal fluid steam generators typically have simpler designs and fewer components compared to boilers, resulting in lower maintenance requirements and costs. They do not require water treatment or blowdown systems, reducing maintenance efforts further.

Faster Start-up and Shutdown: Thermal fluid steam generators have faster start-up and shutdown times compared to boilers. This allows for quicker response to changes in heat demand and improved operational efficiency.

High Pressure Condensate Return Systems

An industrial process steam generator is typically equipped with a highly efficient High Pressure Return (HPR) System. This system plays a vital role in collecting the condensate generated during the process, enabling its treatment and subsequent return to the steam generator. By incorporating an HPR system, the overall efficiency of any steam system can be significantly enhanced, resulting in operational improvements ranging from 15% to 35%.

The HPR system facilitates the return of high-temperature condensate to the feed system. This unique feature ensures that the condensate remains above its boiling point, preventing the loss of valuable thermal energy in the form of BTUs. As a result, millions of BTUs are saved annually by effectively containing the heat loss within the condensate, leading to substantial energy conservation.

Learn more about how an HPR System can help you save 15 to 35% on fuel bills!

Click here to view Steam Property Tables.

Find Out How Our Industrial Process Steam Generators Can Benefit Your Facility

If you’re in need of an industrial steam generator that’s reliable, efficient, and requires minimal maintenance, you’ve come to the right place. Our thermal fluid steam generators are appropriate for a variety of industrial applications in a number of industries. They can help your facility run more efficiently, saving your company money in the long- and short-term.

Ready to learn more about thermal fluid steam generators from Enerquip? Contact us today! Complete our online form to request more information or give us a call at (715) 748-5888. Have additional questions about steam generators? Curious about their benefits when compared to hot oil boilers? Find answers to frequently asked questions about industrial steam generators here!