Waste Heat Recovery Solutions

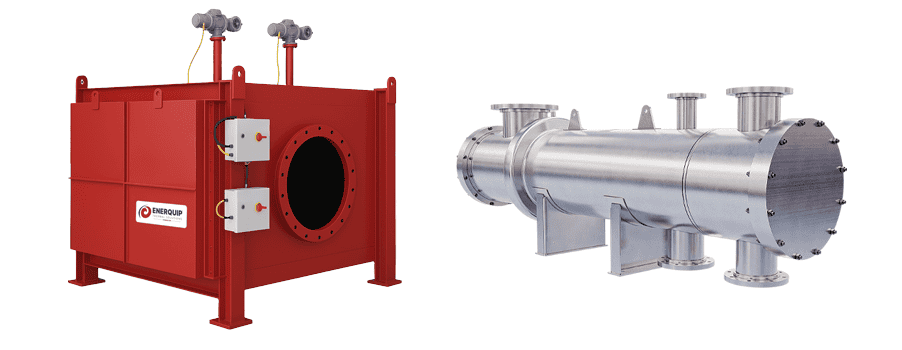

Recovering waste heat is one of the most effective ways to improve plant efficiency and reduce fuel consumption. Enerquip designs and manufactures two proven options for waste heat recovery:

- Waste heat economizers (below, left) that capture and reuse high-temperature exhaust

- Shell and tube heat exchangers (below, right) that recover process heat and put it back to work

These solutions are engineered for demanding industrial environments and tailored to each application—whether installed as standalone equipment or integrated into a complete heating system.

Estimate your potential savings with our Economizer ROI and Fuel Savings Calculator.

Waste Heat Economizers

Enerquip waste heat economizers are designed to recover energy from high-temperature flue gas, typically above 1,000°F. These units capture heat from exhaust streams leaving equipment such as thermal oxidizers, incinerators, turbines, and gasifiers.

Recovered heat is commonly used to:

- Heat thermal fluid (hot oil), asphalt, water, or glycol

- Preheat process streams

- Reduce fuel demand in downstream heaters

Enerquip economizers are included as part of our serpentine coil thermal fluid heaters or can be supplied as standalone units, increasing overall system efficiency while minimizing footprint.

Serpentine Coil Thermal Fluid Heater with a built-in economizer

Waste Heat Economizer Design Features

Enerquip economizers are engineered using rigorous API-based design practices and built to withstand harsh industrial service. Units are available with finned or bare pipe, selected based on gas temperature, fouling potential, and heat transfer requirements.

Our economizers are used across industries including, chemical processing, refining, tank terminals, and asphalt production. They are designed to handle dirty gas streams and high particulate loading commonly found in industrial applications.

Design features include:

- Soot blower lanes and soot blowers

- Castable refractory throughout the unit

- Maintenance access between sections

- Removable header boxes

Shell and Tube Heat Exchangers

In applications where waste heat is available from process streams, Enerquip designs and manufactures shell and tube heat exchangers for skidded systems.

These systems are commonly used to:

- Recycle or reuse process heat

- Transfer recovered energy between fluids

- Improve overall thermal efficiency across the facility

Shell and tube heat exchangers offer flexibility in design and materials, allowing Enerquip to match the exchanger to the specific temperatures, pressures, and fluids involved.

Benefits of Waste Heat Recovery

Implementing a waste heat recovery system can deliver measurable operational and financial benefits, including:

Lower Energy Costs: Recovered heat reduces fuel consumption and overall energy spend by reusing heat that would otherwise be lost.

Improved Efficiency: Capturing waste heat improves overall system efficiency and reduces the load on primary heaters.

Reduced Capital Investment: Waste heat recovery often provides a cost-effective alternative to installing new heating equipment.

Improved Sustainability: Lower fuel usage reduces greenhouse gas emissions and may help facilities qualify for incentives, tax credits, or sustainability programs.

Estimate your savings with our Economizer ROI and Fuel Savings Calculator.

Reclaiming Lost Energy

Waste heat can be recovered in several ways, depending on temperature, process conditions, and how the recovered energy will be used. The following are common waste heat recovery approaches used in industrial facilities. Enerquip supports these applications through economizers and shell and tube heat exchangers.

Exhaust Waste Heat Recovery: Exhaust waste heat recovery captures energy from flue or stack gases and reuses it elsewhere in the process. This heat is often recovered using economizers or heat exchangers that transfer energy from exhaust gas to a usable fluid, improving overall combustion efficiency in ovens, furnaces, and boilers.

Heat Pump Waste Heat Recovery: Heat pumps are one method of upgrading low-grade waste heat for reuse elsewhere in a facility. Shell and tube heat exchangers are commonly used within these systems to transfer process heat to or from the working fluid.

Flue Gas Heat Recovery: Flue gas heat recovery is commonly achieved using heat exchangers or economizers to transfer energy from combustion exhaust to a process fluid. Enerquip economizers are designed specifically for high-temperature flue gas applications found in industrial operations.

Preheating Asphalt Using Waste Heat: Asphalt must be heated to remain pliable for pumping. Economizers and heat exchangers are commonly used to preheat asphalt from approximately 180°F to 300°F before it enters a final heater for production. This reduces fuel consumption while maintaining consistent processing temperatures.

Increase Waste Heat Recovery With Enerquip

Enerquip designs and builds waste heat recovery equipment tailored to your process, temperatures, and operating conditions. Whether you need a standalone economizer, an exchanger, or an integrated thermal fluid heating system, our team can help you reclaim lost energy and improve efficiency.