Thermal Fluid Heater's from Enerquip

Thermal Fluid Heater Operation

Thermal fluid heaters (also known as hot oil heaters) are used to heat process fluids in a closed-loop system. A heat transfer fluid—typically mineral or synthetic oil—is heated by a gas-fired burner and circulated throughout the system, delivering consistent, controlled heat to the process.

These systems play a critical role in daily operations across industries such as asphalt, refining, and tank terminals, where reliable heat and precise temperature control are essential to productivity and safety.

When a thermal fluid heating system is designed and operated efficiently, it helps facilities:

- Maintain stable process temperatures

- Reduce fuel consumption and operating costs

- Extend fluid and equipment life

- Minimize downtime and unplanned maintenance

- Operate confidently at higher process temperatures

Enerquip thermal fluid heaters are engineered to deliver these results. With high-efficiency designs, optimized heat transfer, and precise control, our systems support reliable operation, improved efficiency, and long-term performance—helping your facility get more value from every BTU.

Thermal Fluid Heater Configurations

Backed by decades of experience, our engineered systems use proprietary thermal design software to solve performance issues and deliver exceptional fuel efficiency.

Standard features and available configurations:

- Radiant heating coil: Serpentine or helically wound

- Sizes: 1.3 to 40 MM BTU/hr. Need something larger? Let’s talk.

- Emissions options: Standard (80 to 120 ppm), Low NOx (<30 ppm), or Ultra Low NOx (<9 PPM)

- Burner: High-efficiency gas-fired burner with burner management system (BMS)

- Finned convection section: Built-in economizer (serpentine coil heaters); recovers waste heat to improve efficiency by up to 10%

- Recirculation pump(s)

- Control panel: NEMA 4 panel with integrated safety features and alarms

- Fuel train: Pre-piped and pre-wired for natural gas and/or alternate fuels

- Expansion tank: 1,000-gallon tank

Optional add-ons or upgrades:

- Tank stand: Available upon request in various custom sizes

- Control panel: NEMA 4X, app connectivity for remote diagnostics

- Expansion tank: 250 to 3,000 gallons with optional nitrogen blanketing

Optional start-up support includes:

- Review of installed work and piping

- Supervision of system fill and oil circulation

- Burner tuning

- Testing of circuits and safety devices

- Operator training for monitoring and safe operation

- Troubleshooting as required

💡What’s the payback period for a new serpentine coil thermal fluid heater? Calculate it here.

Serpentine vs. Helical Coil

Enerquip offers not one, but two proven paths when it comes to thermal fluid heater design: helical coil for a compact, economical footprint—or serpentine coil for more even heating and increased efficiency. Compare them below.

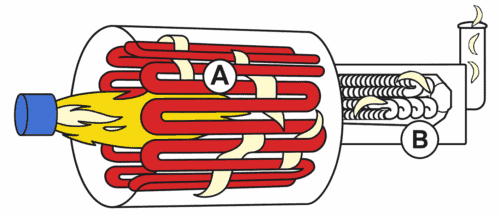

Serpentine Coil Heat ExchangeSerpentine coils use a zig-zag tube layout, providing more even heat distribution. In the radiant section of the heater (A), heat is transferred to the front, sides and back of the serpentine coil. This allows for better heat transfer, less coil degradation, longer tube life, and higher operating oil temperatures. In the convection section (B) of our serpentine coil, heat is transferred to a much larger surface area in our integrated economizer. This reduces stack temperature and increases efficiency by 10–15%. Curious what that efficiency gain looks like in dollars? Try our ROI Calculator.

Serpentine Coil with Finned Economizer |

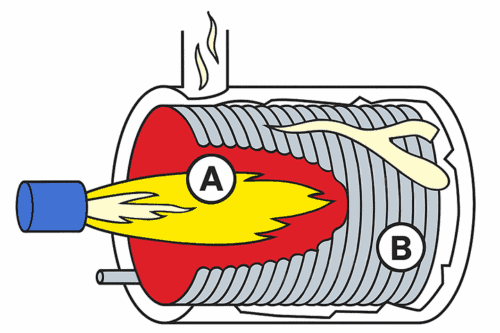

Helical Coil Heat ExchangeHelical coils are wound in a spiral shape and heated primarily from one direction. In the radiant section of the heater (A), heat is transferred by direct radiation only on the inside surface of the helical coil. Convection (B) only occurs as the vapors pass over the outside surface of the helically wound coils, before leaving the stack at a much higher temperature. This design is typically more compact and economical.

Helical Coil |

Thermal Fluid Heater Applications

Industrial thermal fluid heaters from Enerquip can be utilized in a wide variety of applications and industries, some of which include:

- Alkyd paints and resin kettle heating

- Asphalt preheating

- Biofuels blending

- Chemical process heating

- Hot oil steam generation

- Lube oil and fuel oil heating

- Petroleum refining

- Rubbers, plastics and paper processing heat

- Tanker and barge heating

- Tank Terminal heating

- Synthetic fiber production surface coatings curing

Some organizations in these industries still rely on steam boilers to meet their industrial heating needs. If you are one of these organizations and you’re thinking of switching to thermal fluid heat, we highly recommend you make the switch. Find out why hot oil is often preferred over steam.

For the Best in Thermal Fluid Heaters, Choose Enerquip

If you’re considering replacing or upgrading your heating equipment, Enerquip can help! Our team of skilled engineers can work with you to assess your heating needs and design a thermal fluid heater that will increase your plant’s efficiency.