Suction heaters are a type of industrial heat exchanger used in a variety of industrial contexts to heat viscous fluids, including asphalt and fuel oil, to a temperature at which they can be pumped.

Keeping entire tanks of these types of liquids at pumping temperatures can be prohibitively expensive. Suction heaters heat only the liquid being pumped through them instead of heating an entire storage tank of products. As a result, suction heaters are an economical, cost-effective option for plants and facilities in a variety of industries.

How Suction Heaters Work with Other Industrial Heating Equipment

In processes where the contents of a tank must always remain warm and pliable, plant operations may use a combination of equipment.

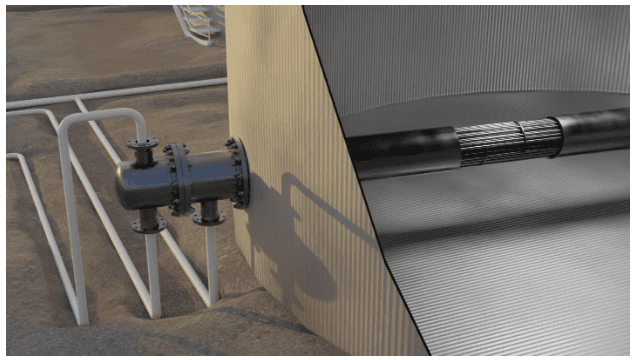

They may heat the entire contents of the tank with tank heating coils sitting at the bottom of the tank. Others may use a bayonet heater which is a tube bundle inserted through a manway on the side of the tank.

Warmed contents are then warmed again as they’re pulled out of a tank through a suction heater. Many times, in colder climates, this is a necessary process.

Industrial Suction Heaters Built to ASME Code

Our standard and custom suction heater solutions are fully built to ASME code. Every Enerquip industrial heat exchanger is reviewed by a third-party inspector during fabrication and hydro testing. We can also design heat exchangers according to international codes. In addition, we can apply customer-supplied nozzle loadings and seismic or other site considerations if requested.

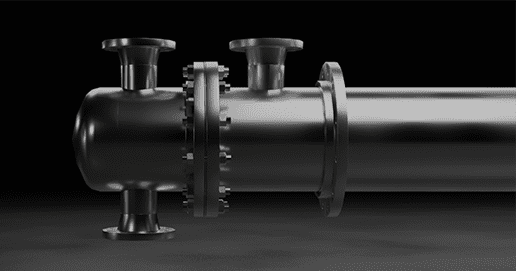

At Enerquip, we’re proud to offer numerous high-quality industrial heat exchangers, including custom-built suction heaters. They’re comprised of a collection of tube bundles mounted inside a shell, which is open at one end and closed at the other. Fluid flows in, where it’s heated with a heat-transfer medium (hot oil, steam, or different fluids). Once hot enough, the suction heater pumps the product out of the tank on demand.

Suction Heater Installed Through a Manway on a Tank

We design our suction heaters with ANSI mounting flanges that bolt onto the manway flange of the tank. Depending on the suction heater’s application, lapjoint, NPT threaded, and sanitary tri-clamp connections are also available.

Enerquip has decades of experience fabricating stainless steel equipment. Along with carbon steel and 304L and 316L stainless steel designs, our suction heaters can also be constructed from a wider range of corrosion-resistant materials upon request.

Built with the highest quality materials and fabrication, our suction heaters are built to last for decades. They are designed for minimal maintenance. Enerquip’s suction heater technology helps facilities pump the most essential viscous materials more smoothly, efficiently, and cost-effectively.

Advanced Suction Heater Solutions

Enerquip has been an industry leader in suction heater and industrial heat exchanger technologies since 1985. Our American-made heat exchangers help clients in numerous industries maintain greater operational efficiency while reducing energy waste and costs.

In 2021, Enerquip acquired American Heating Company, further expanding our industrial heating systems manufacturing capabilities. We are dedicated to improving industrial pumping applications across the country, as well as for our international clients.

Contact us to ask our experienced sales engineers how suction heaters can improve your industrial pumping operations or request a quote today.