As a trusted resource for high-quality, reliable asphalt heaters and heating systems, many of the world’s largest roofing and asphalt manufacturers turn to us to fulfill their industrial heating needs. Learn how our industrial heating equipment works throughout an asphalt plant operation.

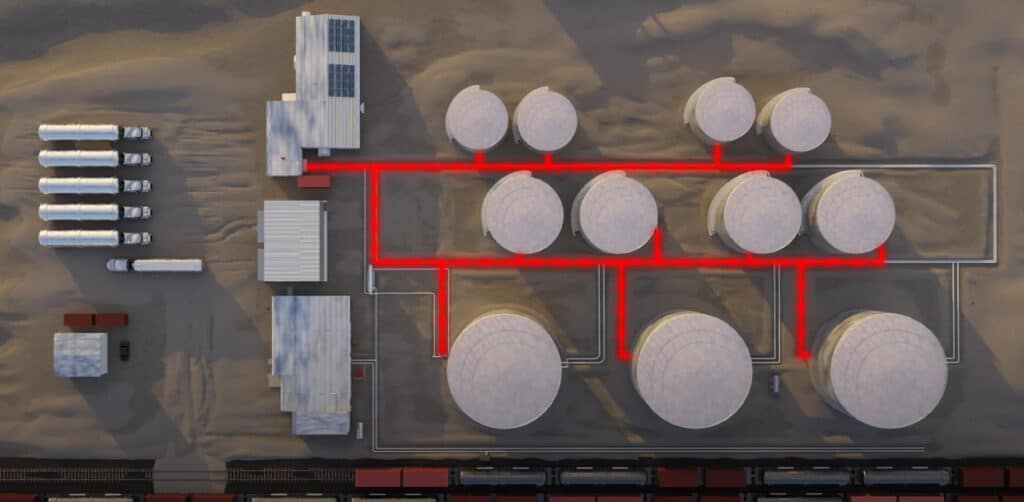

Hot oil heaters in an asphalt plant

Asphalt slurry must be warm to efficiently pump through an asphalt plant operation. Many pieces make up the network to process quality asphalt, but a high-efficiency hot oil heater is at the center of that system.

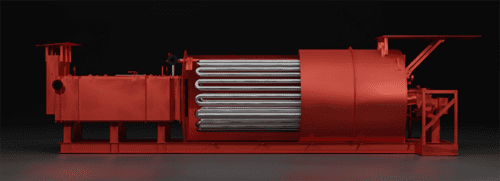

Hot oil flows through the serpentine coil and the attached economizer section for maximum efficiency. The serpentine coil offers more even heat distribution vs. the basic helical coil heater. In addition, the serpentine coil offers higher operating temperatures and lower flow rates which help reduce operating costs.

Serpentine Coil Thermal Fluid Heater

Often, through choice or regulation, plant managers request low NOx options. Through flue gas recirculation, our thermal fluid heaters can reduce emissions down to 9 parts per million.

Hot oil then continues its flow through a system of pipes and out to the rest of the plant.

Tank heating solutions in an asphalt plant

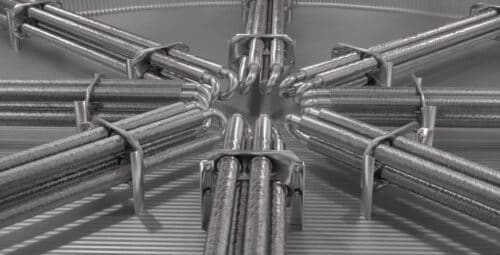

In order to keep the asphalt slurry pliable, the hot oil flows through the tank heating coils in a serpentine fashion. Tank coils are often designed in a star layout for even heat distribution. Depending on process conditions, we may recommend bare or helically wound tank coils made of either carbon or 316L stainless steel.

Helically Wound Finned Tank Heating Coils Built from 316L Stainless Steel

When it’s time for the asphalt slurry to be pumped from the tank, it may need an extra boost of heat. A suction heater can be bolted to the side of a tank through a manway. The hot oil flows through the tube side of the suction heater as the asphalt is pumped through the shell side.

As the asphalt slurry makes its way to be pumped out for transport, the long travel may reduce its temperature. On its last pass, the asphalt will pass through the shell side of the inline shell and tube heat exchanger while the hot oil passes through the bundle. The asphalt is now ready for pumping and transport.

On the other side of the plant, railcars are coming in with fresh asphalt slurry. It’s imperative to keep the asphalt warm so it can be pumped from the railcars to the storage tanks. A steam generator is often connected to the railcars through a series of piping. Hot oil is pumped from the hot oil heater, through the bundle of the steam generator. As water in the steam generator comes in contact with the hot bundle, steam is produced. The steam is then transported to the railcars, keeping the asphalt pliable and ready for pumping.

Looking to the future

In addition to building the highest-quality asphalt equipment, we can help you plan for future equipment needs. Whether you’re in the market to update a portion of your asphalt heating system or need a quote for a new customized asphalt heating system designed to suit your plant, our team can help. Contact us, request a quote, or call us at 715-748-5888.

More from the Enerquip Blog

Industrial Tank Heating Coil FAQs

Tips for Increasing Asphalt Plant Efficiency