Unlocking the intricacies of heat exchange involves navigating through a maze of specialized terminology and cryptic acronyms. In this comprehensive guide, we’ll demystify the language of heat exchange, empowering you with a deeper understanding of the crucial terms and abbreviations that drive this dynamic field.

Whether you’re a seasoned professional or just dipping your toes into the world of thermal management, this resource will shed light on the essential concepts that underpin efficient heat transfer processes.

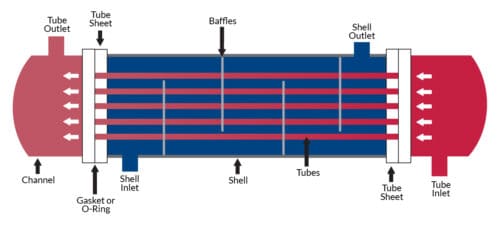

Shell and Tube Heat Exchanger Components

From chemical to food processing, shell and tube heat exchangers play a vital role in various industries. Understanding their design is crucial for appreciating their efficiency and effectiveness in heat transfer applications. Here, we’ll dive into each of their many parts.

Straight Tube Shell and Tube Heat Exchanger

Bonnet, Channel, or Head: The cover or casing that encloses the tube bundle at the front and back of the exchanger. These can be fixed or removable to provide access for maintenance and tube cleaning.

Shell: The outer, cylindrical casing of the heat exchanger.

Tubes: Narrow pipes carrying one of the fluids/gases to be heated or cooled inside the shell.

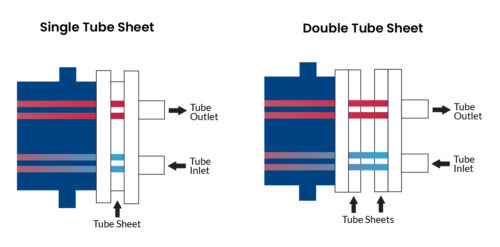

Tube Sheet: Flat plate that supports and seals the ends of the tubes, ensuring separation between the tube side and shell side fluids.

Double Tube Sheet: Just as the name suggests, these exchangers have not one, but two tube sheets. The gap between the tube sheets allows for easy leak detection, and prevents cross-contamination in the case of a failure of a tube-to-tube sheet joint.

Tube Bundle: Refers to the tubes and tube sheet(s) inside the shell.

Baffles: A series of dividers placed inside the shell to direct the flow of fluid. They help improve heat transfer by creating turbulence in the fluid, which enhances the exchange of heat between the fluid inside the tubes and the fluid surrounding them in the shell.

Tie Rods: Metal bars that run through the length of the heat exchanger shell to provide structural support and stability to the tube bundle assembly.

Spacers: Metal plates placed between the baffles to maintain proper spacing and alignment. Spacers prevent the baffles from moving in service, which could lead to vibration and inefficient heat transfer.

Gasket: Seal used between the tube sheet and the shell, ensuring that the shell side and tube side fluids do not mix.

O-Ring: Rubber seal used between the tube sheet and the shell, ensuring that the shell side and tube side fluids do not mix.

Tube Inlet: The flange where fluid/gas flows into the tubes of the exchanger.

Tube Outlet: The flange where fluid/gas flows out of the tubes of the exchanger.

Shell Inlet: The flange where fluid/gas flows into the shell of the exchanger.

Shell Outlet: The flange where fluid/gas flows out of the shell of the exchanger.

Expansion joint: With two common designs – bellows or flanged and flued – expansion joints offer a place on the exchanger where thermal expansion can occur safely.

Lifting Lug: Small, reinforced attachment point welded onto the shell of the heat exchanger to facilitate lifting during installation, maintenance, or relocation processes.

Mounting Legs: Supportive structures welded to the bottom of the exchanger, providing stability and elevation.

Shell Side: The space within the shell where a heat exchange fluid/gas flows.

Tube Side: The space inside the tubes where a heat exchange fluid/gas flows.

Thermal Exchange of a Shell and Tube Heat Exchanger

Heat Transfer Rate: The amount of heat energy transferred between the shell side and tube side fluids per unit of time, typically expressed in terms of BTU per hour.

Passes: The number of times the same tubeside fluid/gas flows through the length of a shell and tube exchanger. For example, a “two-pass” heat exchanger means the fluid flows the length of the unit twice (down and back).

Parallel Flow Arrangement: Both the hot and cold fluids flow in the same direction within the heat exchanger, typically from one end to the other.

Counterflow Arrangement: Arrangement where the hot and cold fluids flow in opposite directions within the heat exchanger. The hot fluid enters at one end, while the cold fluid enters at the other end.

Crossflow Arrangement: The hot and cold fluids flow perpendicular to each other, with one passing through the tubes and the other passing over the exterior of the tubes.

Closed Circuit: A system where the shell side and tube side fluids remain enclosed within their respective channels and do not mix with the external environment.

Shell and Tube Heat Exchanger Tube Configurations

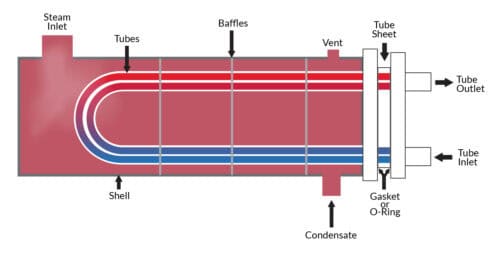

U-tube Heat Exchanger: The tubes within the exchanger are bent into a U-shape, allowing for thermal expansion without the need for floating tube sheets. The bundle is removable to allow for easy cleaning and maintenance.

Straight Tube Heat Exchanger: The tubes within an exchanger run straight through the shell without bending or curving. The bundle could be removable or not.

U-Tube Shell and Tube Heat Exchanger

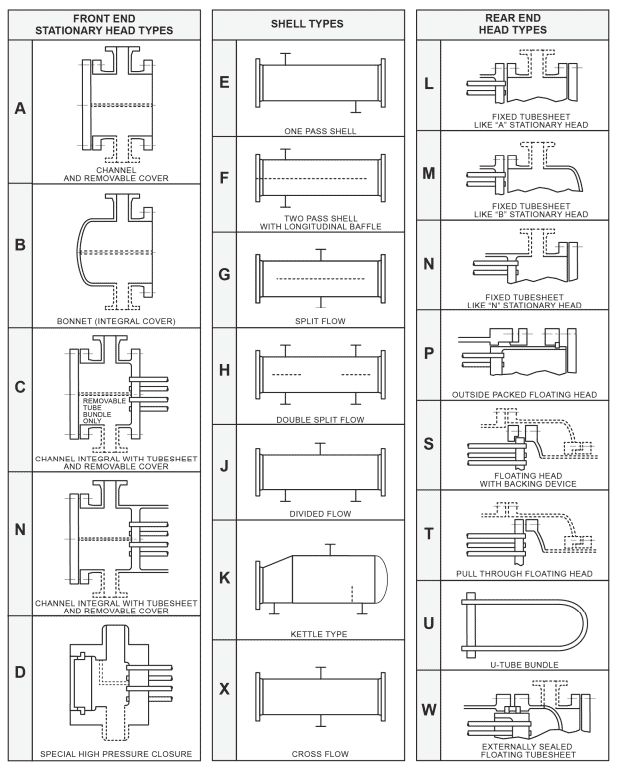

TEMA Styles of Shell and Tube Heat Exchangers

Shell and tube heat exchangers comprise of the stationary front-end head (bonnet/channel), the tube bundle, the rear head, and the shell. These components can be configured in various ways to suit different applications. The TEMA classification system categorizes these configurations into different types:

Channel Types: A, B, C, N, D. These describe the arrangement of the channels within the exchanger.

Shell Types: E, F, G, H, J, K, X. These indicate variations in the shell geometry and construction.

Rear-end Head Types: L, M, N, P, S, T, U, W. These refer to different types of rear heads.

Additionally, TEMA defines specific designs for certain applications, such as:

Fixed Tube Sheet: BEM, AEM, NEN. These designs have stationary tube sheets, suitable for applications where fluid temperatures and pressures remain constant.

Floating Head: AEW, BEW, AES, BES, AET, BET, AEP. These designs allow for differential thermal expansion between the shell and tube bundle, making them suitable for high-pressure or high-temperature applications.

U-Tube: BEU, AEU, CFU. U-tube exchangers are characterized by a U-shaped tube bundle configuration, offering simplicity and ease of maintenance.

Kettle Reboiler: AKT. This design is specifically tailored for use as a reboiler in distillation or similar processes, where one fluid is vaporized to heat another fluid.

By understanding these classifications and designs, engineers can select the most appropriate shell and tube heat exchanger configuration for their specific heating or cooling needs.

Source: TEMA

Common Shell and Tube Heat Exchanger Duties

Below we’ll highlight some of the crucial roles shell and tube heat exchangers play in preheating, distillation, sanitation, temperature control, and more.

Preheater: Used to elevate the temperature of one fluid (typically the colder one) before its entry into another heating system or process, thereby enhancing energy efficiency.

Reboiler: Serves in distillation operations by facilitating the vaporization of a liquid to enable further separation and refinement.

Clean-In-Place (CIP) Heater: Integral in sanitary industries for proficiently transferring heat between fluids while enabling automated cleaning procedures without requiring disassembly.

Water-for-Injection (WFI): Engineered to produce high-quality water for pharmaceutical applications, adhering to stringent purity standards through efficient heat transfer between water streams while ensuring sanitation and water integrity.

Point-of-use (POU) Cooler: Tailored to deliver chilled water at specific locations, commonly within pharmaceutical processes, facilitating temperature control for products, equipment, or sensitive materials.

Process Cooler: Lowers the temperature of process fluids by transferring heat from the hotter fluid to a cooling medium.

Condenser: Converts vapor into liquid by transferring heat from the vapor to a cooling fluid circulating within the tubes.

Clean Steam Generator: Produces high-purity steam by heating water with clean steam or purified water within the tubes, predominantly utilized in pharmaceutical and biotechnology sectors.

Steam Generator: Generates steam by transferring heat from a hot fluid (typically water) circulating through the tubes to water within the shell, commonly employed in power plants and industrial processes.

Evaporators: Engineered to concentrate a solution by vaporizing the solvent from the solution, typically achieved by heating the solution within the tubes to generate vapor, leaving behind a more concentrated solution within the shell.

Codes & Standards Related to Shell and Tube Heat Exchangers

TEMA: The Tubular Exchanger Manufacturers Association (TEMA) is an organization that provides standards for the design, construction, and maintenance of shell and tube heat exchangers. There are three major classifications of equipment: TEMA C (General commercial applications), TEMA B (Chemical applications), TEMA R (Refinery applications).

HTRI: Heat Transfer Research, Inc. (HTRI) is an organization that conducts research and provides software tools and data for heat exchanger design and analysis.

ASME: The American Society of Mechanical Engineers (ASME) is a professional organization that sets standards and codes for mechanical engineering practices, including the design, construction, and inspection of various mechanical systems and equipment, such as boilers, pressure vessels, and piping. These standards ensure safety, reliability, and quality in engineering applications across various industries.

ASME-BPE: Refers to the American Society of Mechanical Engineers – Bioprocessing Equipment (ASME-BPE) standards. These are specific standards developed by ASME for equipment and systems used in the biopharmaceutical industry. ASME-BPE standards cover various aspects of design, materials, fabrication, testing, and documentation for bioprocessing equipment to ensure quality, purity, and safety in the production of biopharmaceutical products.

Enerquip’s Thermal Solutions

Now that we’ve provided you with a foundation in heat exchange principles, we trust that navigating the realm of thermal solutions will seem less daunting.

Alongside our expertise in shell and tube heat exchangers, we also excel in engineering industrial heaters and a variety of tank heating solutions.

If you’d like more information or have some questions, we’d welcome the opportunity to connect. Contact us or request a quote today.

More from the Enerquip Blog

- 7 Ways Shell & Tube Heat Exchangers Outperform Plate & Frame

- The Art and Science of Film Temperature to Achieve Goldilocks Efficiency

- Decoding the Delicate Balance of Sizing Shell and Tube Heat Exchangers

- Insulation Jackets: Enhancing Efficiency and Performance of Shell and Tube Heat Exchangers

- Discover the Hidden Brilliance of Metal Surfaces: Unleash the Power of Electropolishing

- How to Install an Enerquip Bundle into its Shell [Video]