Plate and frame and shell and tube designs stand out as the two most prevalent heat exchangers, offering versatile solutions for heating or cooling products during processing. The fundamental principle of heat exchangers involves the transfer of heat between two media, facilitated by tubes or plates.

Despite the effectiveness of both designs, shell and tube heat exchangers often present distinct advantages over plate and frame configurations in various applications. In the following discussion, we will delve into specific application requirements that make shell and tube heat exchangers the preferred choice.

What is a Shell and Tube Heat Exchanger?

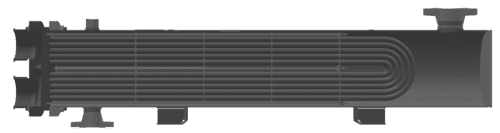

A shell and tube heat exchanger comprises a cylindrical shell housing a tube bundle. One fluid circulates within the shell around the tubing, while another fluid flows through the tubes. The transfer of heat from the hot medium to the cool medium (or vice versa) occurs through the tube walls, offering a generous heat transfer area for efficient heat transmission.

These versatile heat exchangers are capable of operating under parallel, cross-flow, or counter-flow conditions.

Enerquip shell and tube heat exchanger.

What is a Plate and Frame Heat Exchanger?

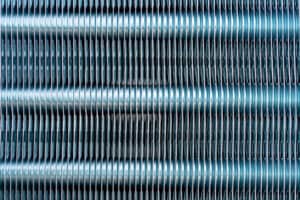

A plate and frame heat exchanger is a type of heat exchanger that consists of thin, corrugated plates arranged in a frame-like structure. These plates are sealed together, creating alternating channels for hot and cold fluids. The design allows for heat transfer between the two fluids without them coming into direct contact.

In operation, the hot and cold fluids flow through separate channels formed by the plates. The corrugations in the plates enhance turbulence, promoting heat exchange. The close proximity of the plates facilitates the transfer of thermal energy from one fluid to the other.

Plates of a plate and frame heat exchanger.

Why Shell and Tube is a better all-around option.

1. Shell and Tube Heat Exchangers can operate at higher temperatures.

Shell and tube designs are very effective for large temperature differences, especially when using a u-tube style. The U-tube bundle within the heat exchanger is fixed to only one tube sheet, allowing the tube bundle to expand and contract as a result to thermal differences. Straight tubes can also handle large temperature differences with the use of expansion joints.

The shell and tube configuration allows for a better distribution of thermal stress across the exchanger, reducing the risk of localized hot spots. The larger passages and open design contribute to improved fluid flow and heat transfer efficiency at elevated temperatures.

In contrast, the closely spaced plates in plate and frame heat exchangers may pose challenges in maintaining integrity and thermal performance under high-temperature conditions.

Enerquip sanitary shell and tube heat exchangers with process temps upwards of 315°F. The insulation jacket increases thermal efficiency while providing a safety barrier for high heat.

2. Shell and Tube Heat Exchangers can handle higher operating pressures.

Shell and tube heat exchangers are often considered more suitable for higher operating pressures compared to plate and frame heat exchangers for a variety of reasons. First, the shell and tube design inherently provides a robust and sturdy construction that can be built with various-sized tubes and shell thicknesses. Reducing the diameter of the tubes and increasing the thickness of the shell are common options for increasing operating pressures.

Additionally, the design of shell and tube heat exchangers allows for a more straightforward incorporation of materials that can withstand elevated pressures. The cylindrical shell, with its larger cross-sectional area, provides a stable structure that can handle the mechanical stresses associated with higher pressure conditions. This contrasts with plate and frame heat exchangers, where the closely spaced plates may pose challenges in maintaining integrity under increased pressure.

Furthermore, the sealing mechanisms in shell and tube heat exchangers are typically more resilient to higher pressures, especially if choosing an all-welded construction. The gaskets and seals used in plate and frame heat exchangers may be more prone to leakage or failure under elevated pressure conditions.

Enerquip shell and tube heat exchanger built to withstand 2,500 psi for a fuel application.

3. Shell and tube Heat Exchangers are easier to clean and maintain.

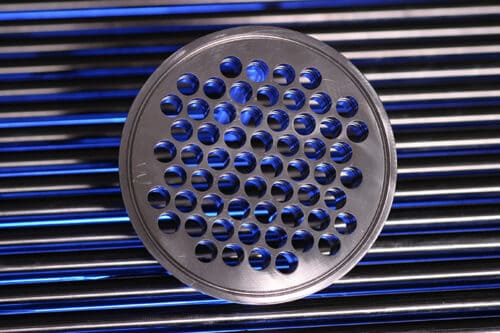

In a shell and tube heat exchanger, accessibility of the tubes allows for straightforward maintenance. Rather than dismantling lots of separate plates and their corresponding gaskets, as with a plate and frame design, you simply remove the bonnet(s) to access the tubes. The larger passages in the tubes also facilitate the removal of debris. Various cleaning methods, including mechanical tools such as Clean-in-place (CIP), and chemical solutions, can be employed.

Learn why you may want to consider mechanically cleaning your shell and tube heat exchanger.

Enerquip tube bundle for a Clean-in-Place (CIP) system.

4. Shell and Tube Heat Exchangers typically offer lower pressure drops.

The larger tube diameter and open design of shell and tube heat exchangers minimizes pressure drop in the system, particularly in high-volume or viscous applications. This applies to both the product side and utility side of your process. This reduced pressure drop can allow the end user to run with smaller pumps, saving energy costs.

5. Shell and Tube Heat Exchangers are less expensive to maintain.

Shell and tube heat exchangers are often less expensive to maintain than plate and frame heat exchangers due to the difference in design, particularly in the number of gaskets and the impact of operating at higher temperatures.

With multiple closely spaced plates sealed together with gaskets, maintaining these gaskets in plate and frame heat exchangers can be labor-intensive and may require more frequent replacements. The close proximity of plates means more gaskets are needed, and each gasket represents a potential point of failure or maintenance concern.

Operating at higher temperatures can accelerate the wear and degradation of gaskets in plate and frame heat exchangers. The increased thermal stress can lead to faster deterioration of gasket materials, necessitating more frequent replacements. This contributes to higher maintenance costs over time.

On the other hand, shell and tube heat exchangers have fewer gaskets and can be replaced by simply removing the bonnet without dismantling the entire unit. Shell and tube can operate at higher temperatures with less impact on gasket longevity.

Shell and tube heat exchangers only require gaskets or O-rings where the tube sheet meets the bonnet, making gasket maintenance minimal.

6. Shell and Tube Heat Exchangers are highly customizable.

Shell and tube heat exchangers offer a superior level of customization compared to plate and frame heat exchangers, providing engineers with greater flexibility in meeting specific heat transfer requirements. This customization extends to various aspects, including configurations and sizes, where the number and arrangement of tubes, as well as the size of the shell, can be tailored to fit the demands of diverse applications.

The ability to choose from a wide range of materials for tubes, shells, and other components allows for customization based on the need to withstand corrosive environments, high temperatures, or other specific conditions.

Engineers can also fine-tune the geometry of the tubes, such as diameter and length, to optimize heat transfer efficiency for particular fluid characteristics. The incorporation of baffles within the shell can be customized to control fluid flow and enhance overall performance.

Additionally, shell and tube heat exchangers demonstrate adaptability to changes in process conditions, making them a versatile choice for applications with evolving requirements.

Custom shell and tube heat exchanger for cannabis processing.

7. Shell and Tube Heat Exchangers can be designed for dual use.

Shell and tube heat exchangers distinguish themselves by their dual-use capability, a feature that sets them apart from plate and frame heat exchangers. This capability stems from the inherent versatility in the design of shell and tube exchangers. Engineers have the flexibility to configure these heat exchangers in various ways, adjusting the number and arrangement of tubes to meet diverse heat transfer requirements. Unlike plate and frame heat exchangers, which are typically designed for a specific purpose, shell and tube exchangers can be adapted for different processes or applications within a single unit.

One key aspect contributing to their dual-use capability is the potential for multi-pass arrangements, where fluids take multiple paths through the exchanger. This design can facilitate turbulent flow with lower flow rates while still achieving a high amount of surface area.

Ideal Applications for Shell and Tube Heat Exchangers

Sanitary and High-Purity Applications: With a more open design, along with stainless steel or higher alloy materials, tri-clamp connections, grooved tube sheets, and option for double tube sheets, shell and tube heat exchangers are often the preferred choice for high-purity applications like sanitary 3-A, personal care, and pharmaceutical. Their accessibility to the tube bundle also facilitates easy cleaning and fouling prevention.

High-Temperature and Pressure Applications: Shell and tube heat exchangers are well-suited for applications involving high temperatures and high pressures such as refinery, petrochemical, food and beverage, and power plant operations. Their robust construction and larger tube diameters make them more capable of withstanding elevated temperatures and pressures compared to plate and frame heat exchangers. In power plants, particularly in the context of cooling systems, shell and tube heat exchangers are commonly employed due to their ability to handle high temperatures and pressures efficiently.

Dual-Use Scenarios and Need for Customization: Shell and tube heat exchangers are versatile and can be customized for dual-use applications, where they need to serve multiple purposes within a single unit. This adaptability is beneficial in processes with changing requirements such as product heating and cooling. In terms of configuration, materials, and geometry, shell and tube heat exchangers offer endless options for customization. The ability to tailor the design to specific needs makes them a preferred choice in such applications.

Corrosive Fluid or Chemical Applications: When dealing with corrosive fluids, shell and tube heat exchangers offer the advantage of material flexibility. Engineers can choose materials that are resistant to corrosion, such as stainless steel, Duplex, Hastelloy, and more, ensuring longevity and reliability in challenging environments. Shell and tube heat exchangers find extensive use in chemical processing industries where the need for corrosion resistance, high temperatures, and customizable designs align with the demands of various chemical processes.

Shell and Tube Heat Exchangers from Enerquip

Since 1985, Enerquip has been a leading supplier in both sanitary and industrial markets. As a trusted provider with a commitment to delivering high-quality solutions, Enerquip’s focus on quality and customer satisfaction continues to drive innovation. Enerquip offers a range of shell and tube heat exchangers designed to meet diverse requirements.

Contact us today to explore the possibilities for your specific application.

More from the Enerquip Blog

- The Art and Science of Film Temperature to Achieve Goldilocks Efficiency

- Decoding the Delicate Balance of Sizing Shell and tube Heat Exchangers

- Machined vs. Fabricated Channels

- Understanding Finish Requirements for Shell and tube Heat Exchangers

- Shell-Side Fluid Challenges: Increasing the Pressure Drop