There are many considerations in selecting a channel/bonnet for your application. Your solution’s budget, accessibility needs and cleaning requirements will help lead you to the best solution for your production process.

Enerquip provides several standard machined and fabricated options. So, what’s the difference?

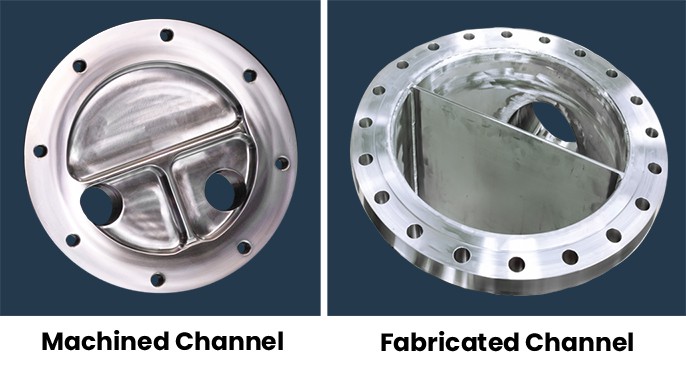

Machined vs. Fabricated Channels

Fabricated designs involve creating parts from raw materials, including a stainless steel flange and pipe cap, typically. More specifically, this design requires cutting, machining, and welding these raw materials together. Machining, on the other hand, starts with a solid piece of stainless steel plate or forging and creates the finished part through milling and drilling.

All of Enerquip’s machined designs are manufactured for cleanability and easy draining through weep holes in the pass partition of a multiple pass unit. Our fabricated designs have larger volume for product hold-up and also can be designed with removable covers for ease of tube cleaning (ideal for more viscous product applications).

For many food and beverage applications, the machined channel may be a better (and more cost-effective) option, while fabricated may be better in some industrial applications.

Let’s look at the benefits to both types of channels and the options available to you through Enerquip.

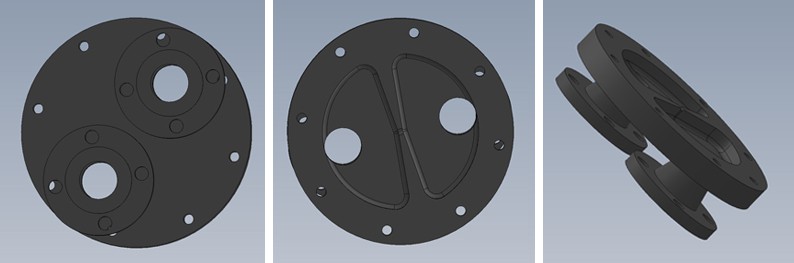

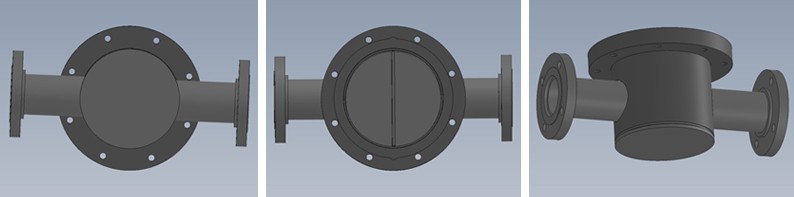

1. Machined Channel with Standard Axial/Straight Flange Connections

Our first design shows our machined channel/bonnet with standard axial/straight nozzle connections for process hook up.

This design is our lowest cost option and is the most compact design – ideal if you have limited space for the exchanger. This design, however, can be more challenging for maintenance, as you must disconnect process piping and remove the channel to access the tube bundle and gaskets.

2. Machined Channel with One Elbowed Connection

The second design is our machined channel/bonnet with one elbowed connection.

This design may be required depending on the size of the process connection compared to the size of the unit. This design is slightly more expensive; however, it gives maintenance a bit more room to access the flange bolting and one less pipe to maneuver around for tube bundle/gasket removal.

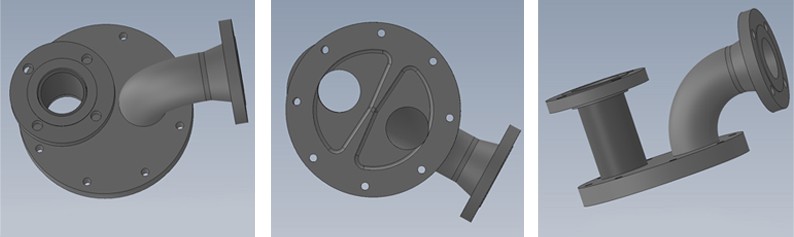

3. Machined Channel with Two Elbowed Connections

The third design has a machined channel/bonnet with two elbowed connections.

This design is the most expensive of the machined designs; however, the extra up-front cost could potentially save you money in the long run due to maintenance costs. This option allows for installation, removal of the process connections, and servicing the unit without interference from the process piping. This leads to less down time for cleaning and repair.

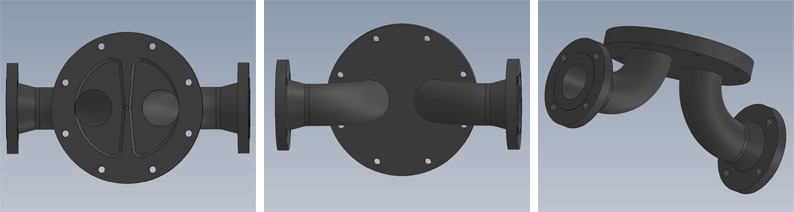

4. Fabricated Channel with True Radial Connections

The fourth standard design is a fabricated channel/bonnet with true radial connections.

This option is good for vapor applications or large liquid flow rates on the process side as the added volume in the channel allows the product to disperse prior to entering the tubes. This is also the preferred option for highly viscous products. While the most expensive option on our list, your maintenance crew will thank you when it comes time for cleaning and repair.

This fabricated design can be built in many configurations, including with elbows on the nozzles, or with a removable end plate for easy access to the tubes.

Enerquip’s Custom Thermal Solutions

No matter your needs, the heat exchanger experts at Enerquip can tailor the design to meet your custom application or finish requirements. From the sanitary requirements of pharmaceutical units to the raw and milled industrial, we are here to take care of you.

Looking for a custom design for your thermal solution? Contact us, today.

Article Author: Will McCarron, Enerquip Sales Engineer