High-Purity Design and Fabrication

At Enerquip, we design and build pharmaceutical-grade shell and tube heat exchangers that meet the industry’s most demanding purity and performance standards. From Clean-in-Place (CIP) systems to Water for Injection (WFI) applications, our exchangers deliver precision, reliability, and cleanability — every time.

Our engineering team uses advanced modeling software to size and select the right exchanger for each heating or cooling application. The result: optimal efficiency, compliance, and long-term dependability.

Suppliers around the world have standardized on Enerquip’s exchangers thanks to our uncompromising quality, sanitary design, and responsive service.

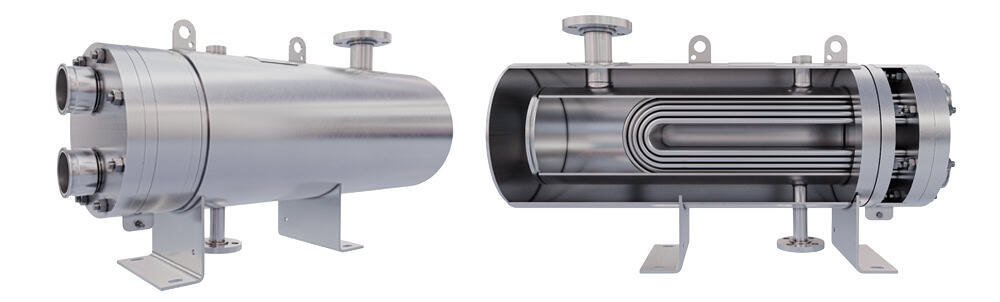

Pharmaceutical-Grade Heat Exchangers

Our pharmaceutical-grade shell and tube heat exchangers can be built up to 48″ in diameter (depending on weight) and are designed with a range of premium upgrades as standard.

Standard Features:

- Material: 316L stainless steel (tube side)

- Finish: Seamless tubes polished to 20Ra, with a 40Ra exterior finish; passivation of product surfaces

- Design: Double tube sheet helps prevent cross-contamination of process fluids between the shell and tubes, and allows for easy leak detection; USP Class VI compliant process side O-rings

- Connections: Tube-to-tube sheet seal-welding, process side tri-clamps, NPT threaded or ASME flanged utility connections

- Nozzle covers: Shell side nozzles are true-vertical to aid in installation

- Pitched to Promote Draining: Fully radiused and polished return pockets and weep slots to enhance cleanability and draining — due to surface tension in highly polished tubes, customer-supplied air or heat may be required to fully drain exchangers

- Compliance: Built to ASME code

- Documentation: Complete and comprehensive pharmaceutical documentation package, including product contact material test reports

Optional Features:

- Materials: Duplex, Hastelloy, AL-6XN

- Additional Styles: Pipe-in-pipe, hairpin

- Finish: 15Ra Electropolish

- Simple Maintenance: Removable tube bundles, inspection ports, O-rings, channel covers

- Design: Welded foot supports and lifting lugs to aid in installation — customer supplied slope can be matched per request

- Accessories & Performance: Sight glasses (utility side), level gauge ports, vacuum breakers, insulation jackets, annular distributors, custom mounting supports, expansion joints, condensate collection sumps/chambers

- Compliance: Built to ASME-BPE code; TEMA Classes C/B/R, PED & other international codes

- Documentation: Custom vendor documentation requirements (VDR) can be reviewed and supplied specific to project needs, including weld procedures

Enerquip Pharmaceutical-Grade Shell and Tube Heat Exchanger

Heat Exchanger Applications for Pharmaceutical Processes

Enerquip’s stainless steel shell and tube heat exchangers deliver the efficiency, cleanliness, and flexibility needed for high-purity pharmaceutical operations. From product heating and cooling to clean steam generation, our equipment supports every stage of your process with reliable, sanitary performance.

Product Heating & Cooling: Consistent temperature control is essential for uniform blending in pharmaceutical manufacturing. Enerquip exchangers maintain steady heating and cooling for both small and large batches, even with viscous products or extreme operating conditions such as high pressure or vacuum. Their polished stainless steel surfaces resist buildup and simplify inspection, ensuring smooth, dependable performance.

Clean-in-Place (CIP) Heating: To meet strict sanitation standards, pharmaceutical facilities often use Clean-in-Place systems that clean equipment without disassembly. Enerquip exchangers heat the cleaning solution—typically steam or hot water—to the precise temperature needed for effective cleaning. This helps prevent cross-contamination and fouling while reducing downtime, labor, and water use.

WFI Heating & Cooling: Water for Injection (WFI) must remain pure throughout production, storage, and distribution. Enerquip exchangers maintain the correct temperature during distillation, reverse osmosis, and recirculation to prevent microbial growth and contamination. Smooth, polished surfaces make cleaning easy and help ensure compliance with stringent purity standards.

Point-of-Use (POU) Cooling: At various points in pharmaceutical production, chilled water is required to maintain stable temperatures for products, equipment, and sensitive materials. Enerquip exchangers provide precise, reliable cooling wherever it’s needed to protect quality and consistency.

Vapor Condensing: During processing, vapor condensers play a key role in capturing and condensing moisture from reactors. Enerquip exchangers support these systems by helping control emissions and maintaining safe, compliant operations.

Clean Steam Generation: For sanitary and high-purity applications, Enerquip exchangers generate clean steam on the tube side to ensure a hygienic, easy-to-maintain process. The resulting pure steam is ideal for sterilization and equipment cleaning. In this configuration, pure water enters the bottom of the exchanger and is heated as it rises through the tubes, while hot oil, plant steam, or waste exhaust passes through the shell side.

Why Choose Enerquip for Your Pharma-Grade Processing Needs?

Enerquip combines decades of engineering expertise with a customer-first approach to deliver heat exchangers that are efficient, reliable, and tailored to your requirements. Our knowledgeable sales engineers are here to guide you through every step, from research to purchase.

Ready to get started? Contact us today.