Protecting Your Investment

When your new process equipment arrives, the countdown to installation might not start right away—and that’s okay. But how you store it in the meantime can make a big difference in the long-term performance and reliability of your system.

At Enerquip, we design our equipment for both indoor and outdoor use. That said, we strongly recommend storing it in a cool, dry, indoor location when possible. If that’s not an option, a little preparation goes a long way in protecting your investment from harsh weather, pests, and environmental contaminants like moisture, dust, pollen, and more.

Here’s how to store each major component to minimize the risk of damage or deterioration before your equipment ever sees action.

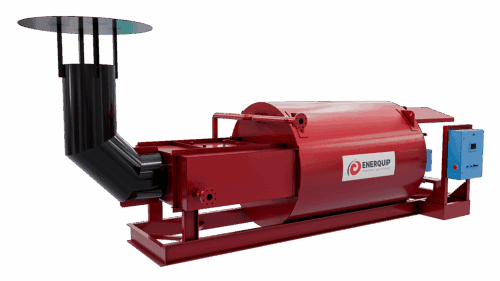

1. Hot Oil Heaters & Asphalt Heaters

Thermal Fluid Heater

These rugged heaters are built for the outdoors—but they still need some TLC during storage:

- Elevate it: Use blocks or railroad ties to keep the unit off the ground and away from mud, snow, or floodwater.

- Protect internal surfaces: Blind flange the inlet and outlet connections, as well as any instrument ports, to keep out moisture and contaminants. For added protection, consider a nitrogen purge inside the pipe coil to help prevent internal rust. While the unit was hydro-tested and pigged twice, residual moisture can still lead to corrosion if not properly addressed.

- Keep pests out: Wrap burner air inlets and panels with plastic wrap and duct tape to discourage birds, insects, and rodents from nesting.

-

Expansion Tank with Nitrogen Blanketing

Cover the exhaust stack: A sheet of plywood wrapped in plastic will keep water and critters out and prevent sagging.

- Secure loose items: Crate and label the fuel train and any accessories, and store them under cover.

- Control humidity: Add desiccant packets inside control panels or junction boxes to reduce moisture build-up.

2. Expansion Tank

Expansion tanks may not take up much space, but they’re just as vulnerable to storage conditions.

- Seal it up: Blind and plug all openings to keep out moisture and pests. A nitrogen blanket is a smart add-on to prevent rust inside.

-

Pump Skid

Store components: If the level gauge or low-flow switch hasn’t been installed yet, crate and clearly label them for safekeeping.

3. Pump Skids

Pump skids often contain several moving parts—making clean, dry storage even more important.

- Keep it elevated: Use blocks or ties to protect against ground moisture.

-

Shell & Tube Heat Exchangers

Seal the system: Blind all open ports. If the skid includes piping, valves, or strainers, a nitrogen purge can help prevent internal corrosion.

4. Heat Exchangers

Heat exchangers are all about performance—and that starts with proper care.

- Seal all openings: Blind flange every port to block dust, moisture, and critters.

- Add a nitrogen blanket: Especially if the exchanger will be stored long term, this can prevent rust from forming on interior surfaces.

5. Tank Coils

Finned Hot Oil Tank Coils

Tank coils are easy to store when done right—but easy to damage if not.

- Elevate and align: Stack coils carefully and off the ground to prevent damage to the fins.

- Seal pipe stubs: Cap or wrap all inlet and outlet stubs to block contaminants.

- Secure loose hardware: Crate and label any shipped leg supports and parts to keep them from getting damaged or misplaced.

Pre-Installation Checklist

Before firing up your system, make sure everything is ready to go with this quick but crucial checklist:

✅️ Inspect for damage: Look for any visible signs of physical or cosmetic damage. If anything looks off, contact Enerquip.

✅️ Grab the manual: You’ll want the equipment manual on hand. Reach out to us if you need another copy.

✅️ Confirm all parts: Make sure all shipped-loose items are present and labeled. If the equipment has been in storage for a while, it might be a good idea to order spare parts like gaskets, seals, or instruments.

✅️ Lubricate moving parts: Lubricate all moving parts according to OEM recommendations – fans, pump shafts, etc.

✅️ Remove moisture controls: Take out desiccant packets and remove any nitrogen purges you used for storage.

✅️ Flush process piping: Clear out any dust or rust particles from the process side of the system.

✅️ Install loose parts: Install any parts that were shipped loose – supports, instruments, sight glasses, etc.

Final Thoughts

Proper storage is more than just a good idea—it’s part of setting your project up for success. A little prep now helps ensure your equipment runs reliably from day one, with fewer surprises and less downtime.

Need help with storage recommendations or replacement parts? Contact the Enerquip team—we’re happy to help.

More from the Enerquip Blog

- 5 Smart Maintenance Tips to Keep Your Shell & Tube Heat Exchanger Performing at Its Best

- The Case for Waste Heat Recovery: Why Your Facility Shouldn’t Ignore It

- Helical vs. Serpentine: What’s the Best Way to Build an Industrial Hot Oil Heater?

- How Evaporation Equipment Powers Food, Pharma, Energy & More

- How Tank Heating Coils Work