Maintaining Your Shell and Tube Heat Exchanger

Leave a CommentEditor’s note: This content was last updated 5/14/24.

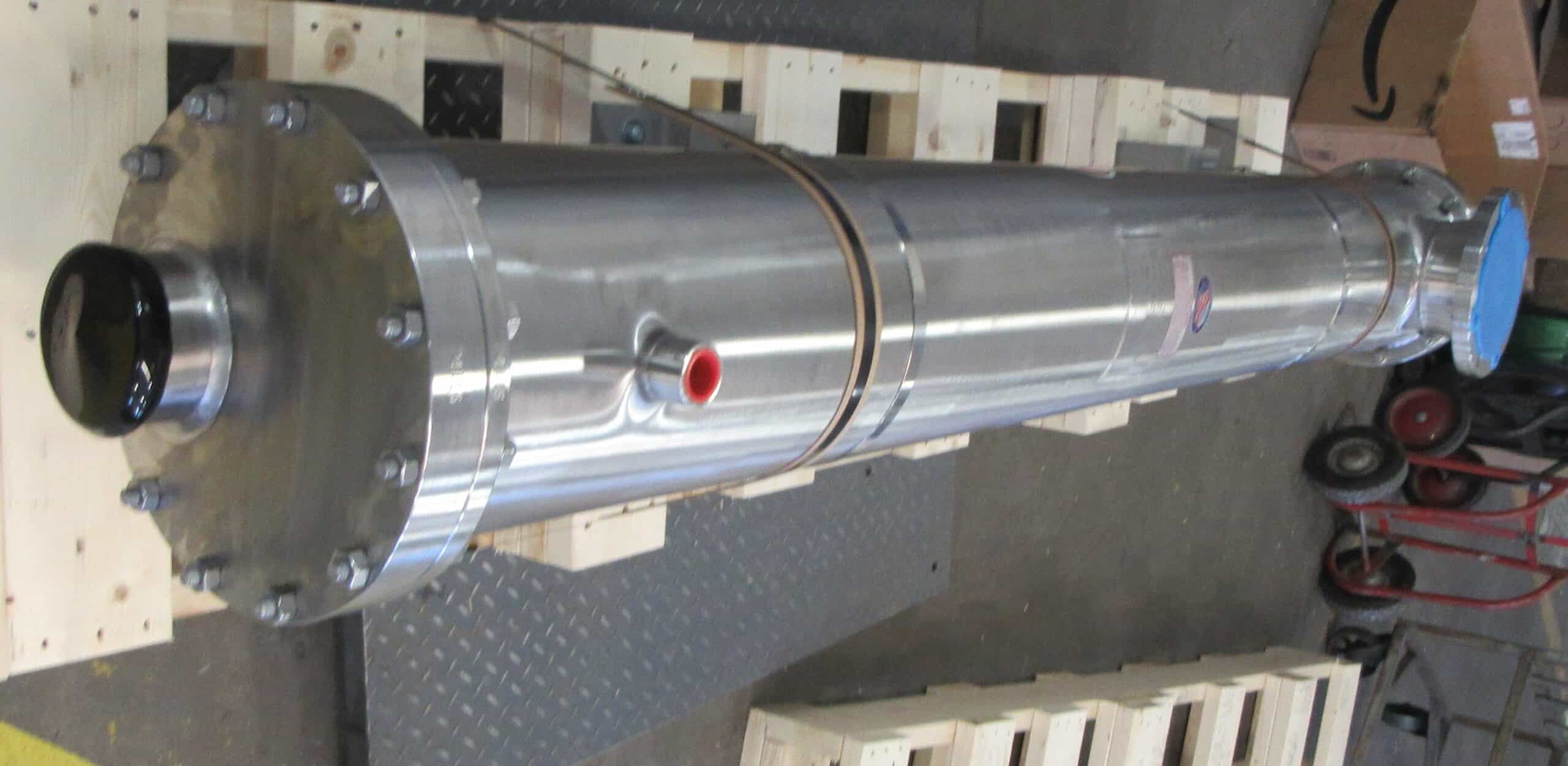

A pivotal component across various operations, the shell and tube heat exchanger stands out as a cornerstone in many processes. In sectors like food, beverage, and dairy, its role in safeguarding consumers from contaminated products is paramount. Similarly, within the pharmaceutical realm, heat exchangers play a vital role in upholding the quality of medications.

The ramifications of a heat exchanger malfunction are significant. Contaminated products result in potential decreases in productivity and, in severe cases, damaging recalls that tarnish reputations. To avert such scenarios, regular review and servicing of the heat exchanger are imperative. Neglecting maintenance leaves heat exchangers vulnerable to corrosion and fouling, which in turn heightens the risk of leaks. These leaks can lead to undesirable mixing of product with cooling or heating fluids, rendering entire batches unusable. Additionally, the accumulation of corrosion and deposits within the exchanger compromises its efficiency, hindering the attainment of desired temperatures.

Corrosion leads to bigger problems

Like any piece of equipment, a shell and tube heat exchanger requires periodic maintenance, including cleaning, repairs, and ultimately replacement. Continuous use will inevitably lead to wear and, potentially, corrosion. The objective is to prolong the exchanger’s operational lifespan for as long as possible. Proper maintenance can extend its longevity for decades, involving meticulous and regular inspections of all components.

Ensuring the heat exchanger’s cleanliness is paramount throughout its lifespan. Prior to initial use, a thorough examination is necessary to confirm proper assembly and to prevent contamination of the tubes and shell by dirt, dust, or other contaminants.

Corrosion is an inevitable process that occurs over time, despite adhering to maintenance schedules. It arises from chemical reactions within or surrounding the heat exchanger. Different metals react differently with various substances. Stainless steel is an optimal choice for exchangers, particularly when handling potentially corrosive substances that could harm other metals like copper alloys. High-alloy grade stainless steel can withstand corrosion from most acidic, alkaline, and chlorinated substances. However, even though the metal exhibits high resistance to corrosion, it will gradually deteriorate with time.

Learn about the many options you have when it comes to heat exchanger material selection.

Water monitoring

The best way to prevent corrosion is to make sure only the best substances for the exchanger’s material makeup enter the machine. Using the correct chemicals to treat and clean the tubes is essential. This information should be obtained before you begin using your heat exchanger to ensure you are prepared for its maintenance from the get-go.

Many heat exchangers use water as the heat transfer liquid. Tap water is generally of an acceptable quality to use in the machine. However, it is important to double check the water before putting it into the exchanger. The pH should be neutral, and the water shouldn’t be polluted or have any bacteria or other contaminates in it. If the water comes from a natural source, is should be treated before entering the tubes.

Learn more about the different types of water for steam applications.

If the water isn’t treated or inspected before entering the exchanger, debris could enter the machine and block the chambers. To prevent this from happening, screens or filters can be installed to keep particles out. If they do enter, they will wear against the tubes and cause corrosion.

Regular monitoring of the heat exchanger’s condition aids in early detection of potential failures before fouling or contamination exacerbate the issue. Assessing water quality serves as an indicator of potential or ongoing failures; cloudy water suggests impurities. Additionally, recording temperature and pressure fluctuations can reveal emerging issues. Reduced efficiency may signal scaling, a solid precipitate formed from chemical reactions, which, over time, leads to fouling and corrosion. Monitoring other parameters such as tube thickness also provides insights into emerging problems.

If you find that you need to replace all or part of your heat exchanger, contact Enerquip today. Need something fast? Review our many stock options.

More from the Enerquip Blog

- Common Questions About Pharma-Grade Shell and Tube Heat Exchangers

- Difference Between Parallel Flow, Counter Flow, and Crossflow Heat Exchangers

- Breaking the Heat Exchanger Code

- 7 Ways Shell & Tube Heat Exchangers Outperform Plate & Frame

- The Art and Science of Film Temperature to Achieve Goldilocks Efficiency