When producing consumable goods like personal care products, every detail matters. Your choices in ingredients, equipment, and processing methods significantly impact each product’s efficacy, profitability, and even safety. Take a closer look at how thermal design considerations can impact your manufacturing operations and five factors to weigh as you explore new equipment investments.

What Is Thermal Design?

Thermal design is a type of engineering that studies the effects of heat energy and thermal transfer in various products. It utilizes thermodynamic principles to develop practical solutions that reduce energy loss, enhance efficiency, and address environmental variables that could impact final product quality.

For the personal care goods industry, actively managing temperature at each stage of production and packaging will result in better final products. By evaluating thermal design considerations in the initial design phase, your organization can create and scale new products, optimize processes for existing products, and operate more efficiently.

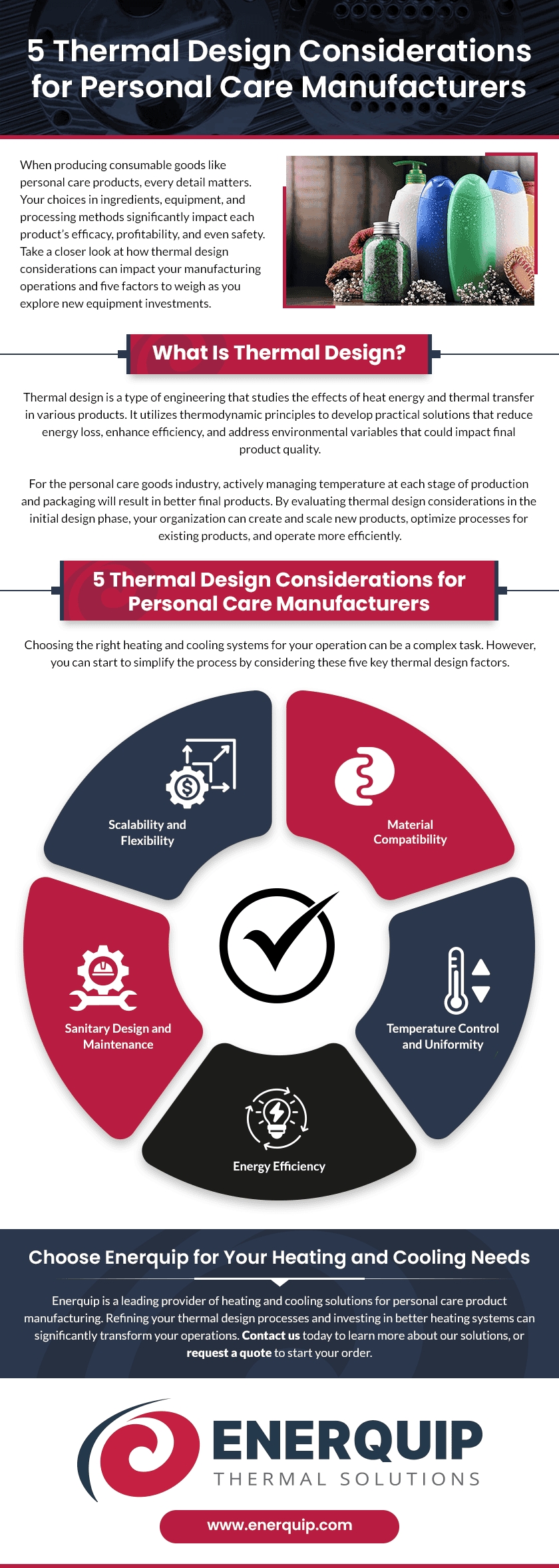

5 Thermal Design Considerations for Personal Care Manufacturers

Choosing the right heating and cooling systems for your operation can be a complex task. However, you can start to simplify the process by considering these five key thermal design factors.

1. Material Compatibility

Select processing and temperature control equipment that won’t degrade when in contact with your personal care products, which may contain corrosive ingredients. Invest in stainless steel or other corrosion-resistant materials for your process equipment, so that the equipment does not react with product ingredients or compromise the safety and quality of the product.

2. Temperature Control and Uniformity

Personal care goods like ointments, lotions, and oils are temperature-sensitive. If the temperature is too high or the processing system contains hotspots, product ingredients can degrade, discolor, lose potency, or separate. All of these outcomes lead to inconsistent final products and dissatisfied customers. Invest in heat exchangers and heating systems that provide reliable, granular temperature control at all stages of production.

The following assemblies, in particular, play a key role in heat consistency and control:

3. Energy Efficiency

Don’t let process heat go to waste. Investing in heat recovery solutions reduces costs and makes your facility run more energy-efficiently. For instance, heat recovery systems can redirect excess heat from vapor condensers to preheat downstream processes. You can also reconfigure your production systems by identifying and eliminating sources of heat loss, optimizing power efficiency for both heating and cooling systems.

4. Sanitary Design and Maintenance

In personal care goods manufacturing, sanitation is a top priority. Products that come into contact with users’ skin or hair must comply with ASME-BPE for cleanliness and hygiene.

However, contaminants can easily build up in crevices or rough patches of processing equipment. That’s why it’s important to use heating assemblies and heat exchangers with smooth surfaces, seamless tubes and components, and minimal crevices. Also, heating machinery should be easy to inspect and clean.

5. Scalability and Flexibility

Finally, invest in heating solutions that can accommodate a wide range of ingredients and product formulations. Demand in the personal care industry is constantly changing as consumers look for new ingredients and formulas that deliver better results. Choose equipment you can easily adapt to produce new goods, scale up production of in-demand products, and accommodate seasonal fluctuations.

Choose Enerquip for Your Heating and Cooling Needs

Enerquip is a leading provider of heating and cooling solutions for personal care product manufacturing. Refining your thermal design processes and investing in better heating systems can significantly transform your operations. Contact us today to learn more about our solutions, or request a quote to start your order.

From the Enerquip Blog

How to Pressure Test Shell & Tube Heat Exchangers

Tube Side or Shell Side: Comparing Fluid Allocation Options for Your Shell and Tube Heat Exchanger

How Static Mixers & Turbulators Improve Heat Exchanger Efficiency

The Art and Science of Film Temperature to Achieve Goldilocks Efficiency

Discover the Hidden Brilliance of Metal Surfaces: Unleash the Power of Electropolishing