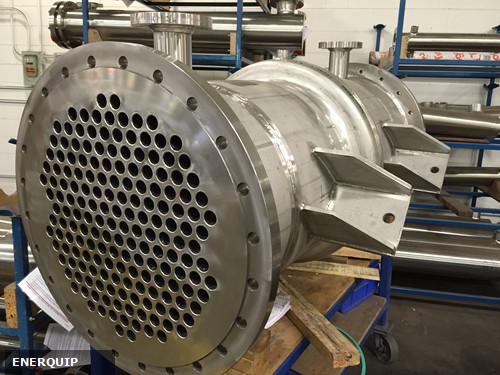

Shell and tube heat exchangers are an integral part of many industries. Though the oil and gas industry may be vastly different from the food and beverage industry, the two have at least one thing in common: the shell and tube heat exchangers that help prepare products for sale to consumers must be in top condition.

When injecting fluid into a shell and tube heat exchanger, that which is more likely to corrode or foul is typically placed in the tube side of the machine, according to R. Shankar Subramanian, a chemical and bioengineering professor at Clarkson University. This is because it is easier to clean or, if needed, replace the tubes than the shell. However, the fact that liquid with a high fouling risk is put into the tube side of the exchanger, makes it crucial that machine operators and owners know how to clean and maintain their tubes.

Shell and tube heat exchangers come in many sizes and configurations. Some are easier to clean than others, primarily because some have tube bundles and bonnets that can be easily removed from the shell side, while others’ are connected to the body of the exchanger. Knowing what type of bonnet your exchanger has and the appropriate cleaning mechanism are critical aspects to consider when purchasing the exchanger.

There are many different ways to clean the tubes of a heat exchanger. Each has its advantages and its disadvantages. The important thing is to know which method is right for your particular machine and operation.

Chemical cleaning

Chemical cleaning is a good method to use for a fixed channel box design, which is generally more difficult to clean because the tubes cannot be separated from the shell. According to Clean-Co Systems, the process for chemical cleaning can be done in several ways. Chemicals can be circulated through the tubes or cascaded. Some are foam and others liquid. Chemicals will vary depending on the type of exchanger and what it is used for. Conoco Systems explained mild acids are typically used for this type of cleaning. It is beneficial to exchangers that have high amounts of buildup, as chemicals remove more deposit than most alternative cleaning methods.

“Chemicals remove more deposit than most alternative cleaning methods.”

However, there are several downsides to using chemicals, Conoco Systems explained. This method is one of the most expensive ones. Also, chances are, the tubes will have to be mechanically cleaned after the chemicals have done their work to remove any residual substances that could contaminate the next product batch inserted into the tubes. It is also time-consuming and a potential environmental hazard.

Hydroblasting

According to Goodway, hydroblasting has been a popular way to clean tubes for many years. This method uses high-pressure water systems to blast away any debris or deposits left in the tubes. NLB Corp. explained the water can be pressurized to as much as 40,000 psi.

Hydroblasting can be done either manually or with an automated system. The manual approach involves an operator hooking a hose up to the tubes one by one and using a foot pedal to regulate the water. This method is effective and relatively inexpensive, though human error may result in uneven cleaning. There are also safety concerns regarding the speed and force at which the water comes out of the hose.

There are two basic types of automated systems: flexible lance and rigid lance systems. Both allow multiple tubes to be cleaned at once, which saves on the amount of time spent cleaning. U-tube heat exchangers and others with curved tubes would benefit from a flexible lance system because it is easy to maneuver the hoses around the bends. For those exchangers with straight tubes, the rigid lance systems provide greater water pressure to remove debris and buildup.

“Flexible lance systems can maneuver around U-shaped bends.”

According to Conoco Systems, operators who choose to use hydroblasting as a cleaning method should also be aware that the pressure of the water could weaken the tubes and create leaks that may go unnoticed. Leaks in the tube side of the exchanger could result in cross contamination between the tube side and shell side fluids. Once discovered, it might even require more time spent offline to repair or replace the tubes.

Chemical cleaning and hydroblasting are two popular ways to maintain the cleanliness of a heat exchanger’s tube side. Deciding which method will depend on the type of exchanger you have and what it is used for. Regardless of the configuration or use of your exchanger, though, it is crucial to ensure the tubes are kept clean to prevent fouling and contamination.