Boilers are essential in many industrial operations—but they can also be major sources of wasted heat and unnecessary energy expense. One of the most effective ways to reclaim lost energy is by installing a condensing economizer—heat-recovery equipment that captures water vapor from boiler exhaust and converts it into usable thermal energy.

Condensing economizers are used across a wide range of industries, including:

- Food and beverage processing

- Pulp and paper mills

- Hospitals and healthcare facilities

- Greenhouses

- District heating systems

- Industrial manufacturing

For operations that rely on steam or process heat, adding a condensing economizer can significantly reduce fuel consumption, cut utility costs, and support sustainability goals.

What Is a Condensing Economizer?

A condensing economizer is a heat-recovery unit that cools boiler flue gas below its natural dew point to capture both sensible heat (from the hot gas itself) and latent heat (released when water vapor condenses).

In a typical natural-gas boiler, flue gas exits the stack at temperatures around 250°F or higher. Cooling it below 135°F, the dew point of water vapor, allows the economizer to reclaim a substantial amount of energy that would otherwise be lost.

This recovered heat can then be used for:

- Preheating boiler feedwater

- Domestic or process hot water

- Space heating

- Other low-temperature process needs

How Condensing Economizers Work

When flue gas passes through the economizer, it is cooled using either a heat-exchange surface or direct water contact. As the vapor condenses, the latent heat released is transferred into a water stream—providing clean, efficient, and reusable energy.

The amount of recoverable heat depends on factors such as:

- Fuel type

- Flue gas temperature

- Boiler load

- Economizer design

- Water temperature entering the system

Recovering latent heat can increase boiler efficiency dramatically, often by 10% or more, depending on operating conditions.

Types of Condensing Economizers

Two primary designs are used in industrial applications, each with distinct advantages.

1. Direct Contact Condensing Economizers

In this design, hot flue gas enters a spray chamber where it comes into direct contact with cool water droplets.

Benefits:

- Very high heat-transfer efficiency

- Effective water recovery

- Simple mechanical design

Limitations:

- Heats water only to ~140°F

- Requires a mist eliminator to prevent droplet carryover

Direct-contact units are ideal when there is a consistent need for low-temperature process water.

2. Indirect Contact Condensing Economizers

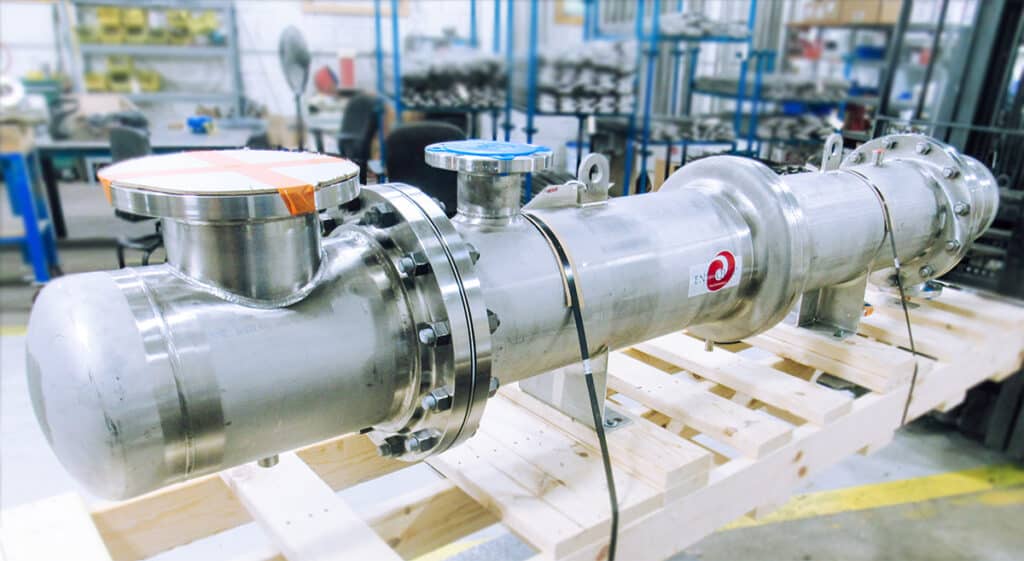

Indirect systems use a shell and tube heat exchanger or similar technology to cool the flue gas without mixing it directly with water.

Benefits:

- Can heat water up to ~200°F

- Can cool flue gas to as low as ~75°F

- Suitable for a wider range of processes

Because they deliver higher water temperatures, indirect economizers are especially useful for preheating boiler feedwater or supporting space and process heating loops.

Example:

A food processing facility installed an indirect condensing economizer to reduce its deaerator steam load. By lowering flue gas temperature from 300°F to 120°F, the unit recovered 2 million BTU/hr and cut deaerator steam demand from 5,000 to 1,500 lbs/hr—resulting in substantial energy and cost savings.

Key Considerations When Selecting a Condensing Economizer

1. Water Quality and Neutralization

Condensate from flue gas is often acidic and must be neutralized before discharge or reuse. Common treatment options include:

- External heat exchangers

- pH control systems

- Filtration or membrane treatment

2. Materials of Construction

Because condensate can be corrosive, selecting durable materials is critical. Stainless steel and corrosion-resistant alloys are commonly used to ensure long-term performance in natural-gas boiler systems.

3. Available Space and Operating Conditions

Not all operations will benefit equally from economizer installation. For example:

- Facilities that already reclaim most blowdown heat may see limited additional savings.

- Plants with minimal demand for low-temperature water may benefit more from an indirect design than a direct-contact system.

A site assessment helps determine the best approach for maximizing heat-recovery potential.

Partnering With Experts for a Customized Solution

Condensing economizers are rarely one-size-fits-all. Each facility has unique operating temperatures, fuel types, water demands, and mechanical constraints.

Working with experienced heat-transfer engineers—like the team at Enerquip—ensures that your condensing economizer or shell and tube heat exchanger is designed, fabricated, and optimized specifically for your process.

If you’re exploring ways to reduce energy consumption, improve boiler efficiency, or meet sustainability goals, a custom heat-recovery solution may deliver substantial long-term value.

Ready to explore your options? Request a quote today.

More from the Enerquip Blog

7 Shell Configurations to Consider When Designing a Shell and Tube Heat Exchanger

What You Need to Know About Cleaning Different Tube Configurations

How Almost Any Industry Can Benefit from Waste Heat Recovery

Offshore Heat Exchangers & Thermal Fluid Heaters: Key Design Considerations