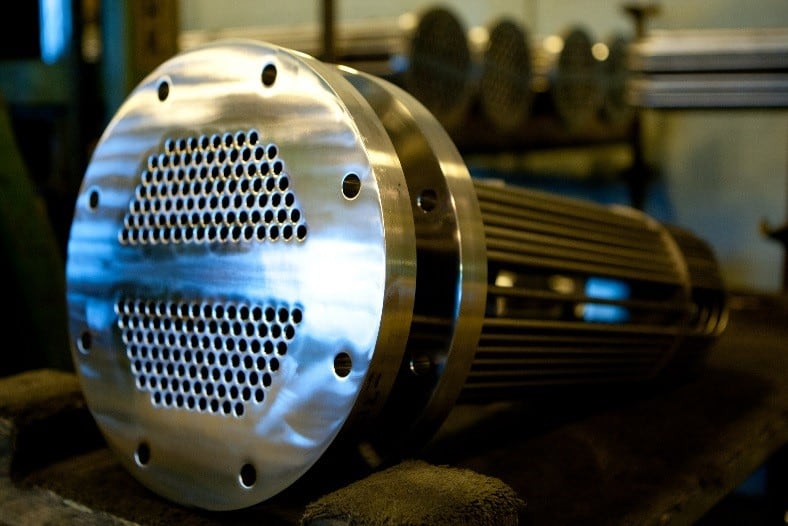

Choosing the right material for a shell and tube heat exchanger, or any type of thermal process equipment, directly affects performance, reliability, maintenance requirements, and total lifecycle cost. With multiple alloys and material combinations available, the best option is rarely about a single factor. Instead, successful material selection balances performance requirements, operating conditions, and long-term value.

This guide outlines the most important criteria to consider when selecting heat exchanger materials and explains how common alloys compare across those criteria.

Key Criteria for Heat Exchanger Material Selection

Before comparing materials, identify which factors matter most for your application. Common priorities include:

- Thermal efficiency

- Cost and availability

- Corrosion resistance

- Cleanability and sanitation

- Durability and service life

In many cases, trade-offs are unavoidable. A material with excellent heat transfer may not meet sanitary requirements, while the most corrosion-resistant alloy may exceed budget constraints. The goal is to find the material, or combination of materials, that best balances your priorities.

Thermal Efficiency

The primary function of a heat exchanger is to transfer heat efficiently between a process fluid (typically on the tube side) and a utility fluid (typically on the shell side). For this reason, the thermal conductivity of tube material is an important consideration.

- High thermal conductivity: Copper and copper-nickel alloys

- Moderate conductivity: Carbon steel, stainless steels, and most high alloys

- Low conductivity: Plastics, graphite composites, and ceramics

Thermal performance can also be enhanced through modification to tubes, such as corrugating, adding external fins to the tubes, or by adding twisted tape turbulators to the inside of the tubes. However, because thermal performance among metals is so similar, this is not usually a high priority factor in heat exchanger material selection.

Cost and Availability

Material cost and lead time vary based on market conditions, alloy composition, and quantity required. In general:

- Alloys with higher nickel content tend to be more expensive

- Common materials are more readily available and have shorter lead times

- Specialty alloys often require longer procurement and fabrication timelines

Relative Cost Ranking of Common Materials

(From highest to lowest cost, subject to market variation)

1. Nickel 200 (UNS N02200): Typically the most expensive and is a commercially pure nickel alloy. It is one of the most widely used nickel alloys due to its excellent mechanical properties and high corrosion resistance. Nickel 200 consists of 99.6% pure nickel, with small amounts of impurities such as iron, copper, and manganese.

2. Alloy 625 (Inconel 625): Nickel-based superalloy known for its excellent strength, corrosion resistance, and high temperature performance. It is composed mainly of nickel, with significant amounts of chromium and molybdenum, along with smaller additions of niobium, iron, and other elements. Alloy 625 is widely used in various industries, including aerospace, chemical processing, oil and gas, and marine applications.

3. Monel 400: Nickel-copper alloy known for its excellent corrosion resistance in various environments. It is composed of approximately 67% nickel and 30% copper, with small amounts of iron, manganese, carbon, and silicon. Monel 400 is highly resistant to corrosive substances such as acids, alkaline solutions, and saltwater. It is often used in applications where resistance to corrosion, erosion, and high temperatures are essential.

4. Hastelloy C22: Nickel-chromium-molybdenum alloy known for its exceptional corrosion resistance in a wide range of aggressive environments. Hastelloy C22 is particularly resistant to pitting, crevice corrosion, and stress corrosion cracking. Hastelloy C22 is often chosen for chemical processing and waste treatment.

5. Hastelloy C-276: Nickel-molybdenum-chromium alloy that is renowned for its corrosion resistance and high-performance properties. While similar to Hastelloy C22, Hastelloy C-276 has lower chromium content, easier weldability, and slightly higher upper temperature limits. Hastelloy C-276 is used in various industries, including chemical processing, pollution control, pulp and paper production, and petrochemical applications.

6. Duplex 2507: Super duplex stainless steel alloy that offers excellent strength, corrosion resistance, and durability. It is part of the duplex stainless steel family, which combines the desirable properties of both austenitic and ferritic stainless steels. Duplex 2507 is characterized by its high levels of chromium, molybdenum, and nitrogen, providing superior resistance to corrosion and high mechanical strength.

7. AL6XN: High-performance austenitic stainless steel alloy that offers exceptional corrosion resistance and mechanical properties. It is specifically designed to withstand highly corrosive environments, including chloride-rich environments, acids, and seawater. AL6XN is known for its versatility, making it suitable for various applications in industries such as chemical processing, pulp and paper, oil and gas, and desalination.

8. Titanium: Lightweight metal known for its high strength, low density, and excellent corrosion resistance. Titanium is widely used in various industries due to its unique combination of properties.

9. Duplex 2205: Stainless steel alloy with a combination of austenitic and ferritic microstructures, known as a duplex structure. It offers excellent strength, corrosion resistance, and durability, making it suitable for a wide range of applications. Duplex 2205 is highly popular in industries such as oil and gas, chemical processing, marine, and pulp and paper.

10. 316L stainless steel: Commonly used and known for its corrosion resistance, high strength, and versatility. It is an austenitic stainless steel alloy with low carbon content, making it suitable for various applications where resistance to corrosive environments is essential. It is widely used in marine applications, chemical processing, dairy, and pharmaceuticals.

10. 304L stainless steel: Commonly used and known for its corrosion resistance, versatility, and ease of fabrication. It is an austenitic stainless steel alloy with low carbon content, which enhances its weldability and reduces the risk of sensitization to intergranular corrosion. In comparison to 316L SS, 304L SS has no molybdenum content and it’s less resistant to chloride-induce corrosion. It is suitable for general-purpose uses that don’t require the enhanced corrosion resistance of 316L SS.

12. Carbon steel: Lowest cost steel that primarily consists of iron and carbon, with other elements present in smaller amounts. It is one of the most commonly used materials in the manufacturing and construction industries due to its affordability, strength, and versatility.

Higher-cost alloys are often produced in smaller volumes, which can significantly affect availability and pricing for small orders. Fabrication complexity and welding requirements can also influence overall cost.

Combining Materials

Heat exchangers do not have to be built from a single material. In fact, using different materials on the shell side and tube side is common and often cost-effective.

Typical strategies include:

- Using higher alloy materials on the product side

- Using lower-cost materials on the utility side

- Selecting higher alloys for tubes rather than shells to reduce material volume

It’s also important to consider tubing type. Seamless tubes generally cost significantly more than welded tubes, which can influence alloy selection.

Additional cost-saving design approaches include:

- Lap-joint flanges with high-alloy stub ends and lower-cost backing flanges

- Clad components, such as tube sheets or flange rings, that combine a base metal with a thin layer of high alloy

Supplier Capabilities and Fabrication Considerations

Not all fabricators work with all materials. Availability of qualified suppliers affects both cost and delivery time.

- Carbon steel and copper exchangers are widely fabricated with competitive pricing

- Stainless steels and duplex alloys require ASME-qualified welding procedures

- Specialty materials such as titanium, zirconium, and tantalum require controlled fabrication environments and specialized expertise

When selecting materials, it’s important to confirm that your chosen supplier has proven experience and certified procedures for the alloys under consideration.

Corrosion Resistance

Corrosion resistance is highly dependent on the process environment, including temperature, chemical composition, concentration, and flow conditions. For critical applications, consulting a metallurgist, such as Rolled Alloys, is strongly recommended.

General material trends include:

- Carbon steel: Prone to corrosion but resistant to some forms of stress corrosion cracking

- Copper and CuNi: Moderate corrosion resistance, commonly used in utility services

- Stainless steels: Suitable for low to moderate corrosion environments

- Duplex stainless steels: Improved resistance to chlorides and stress corrosion cracking

- High-nickel alloys and titanium: Used for aggressive chemical environments

Each alloy resists specific corrosive agents differently, so material selection should always be matched to the actual process chemistry.

To ensure there is no cross contamination between carbon steel and stainless steel, Enerquip’s shop in Medford, WI is carbon-free. Enerquip’s carbon steel equipment is built proudly in Beggs, OK.

Cleanability and Sanitary Requirements

In applications where product purity and maintenance efficiency are critical, cleanability becomes a key driver in material selection.

Important considerations include:

- Compatibility with cleaning methods (chemical, mechanical, ultrasonic)

- Resistance to cleaning agents such as acids, caustics, and chlorides

- Surface finish and roughness

Sanitary Applications

Industries such as food, beverage, dairy, pharmaceutical and cannabis processing typically require:

- Stainless steel or higher alloys for product contact surfaces

- Compliance with FDA, ASME-BPE or 3-A Sanitary Standards

- Controlled surface finishes specified by Ra values

Some pharmaceutical applications also require electropolishing to further enhance cleanability and reduce fouling.

Making the Right Material Choice

Selecting the optimal heat exchanger material requires balancing performance, cost, corrosion resistance, cleanability, and durability. In many cases, the best solution involves combining materials or using higher alloys selectively where they provide the most benefit.

Working with experienced heat exchanger manufacturers and metallurgists can help ensure your material choice aligns with both process demands and long-term operational goals.

Learn more about Enerquip’s shell and tube exchangers, or request a quote today.