From asphalt terminals to biofuel plants to food processing facilities, many industries rely on storage tanks to hold temperature-sensitive materials. Whether it’s keeping asphalt pumpable, blending biofuels at precise temperatures, or preventing crystallization in chemicals, maintaining proper heat is critical.

In the past, some plants relied on direct-fire burners inside tanks to heat flammable materials—a risky practice. Today, tank coils provide a safer, more efficient solution by keeping the heat transfer separate from the stored product.

Tank coils quietly work inside tanks to heat, cool, or regulate stored materials—ensuring consistent quality, safety, and efficiency. But how they’re designed, maintained, and applied makes all the difference.

How Tank Coils Work

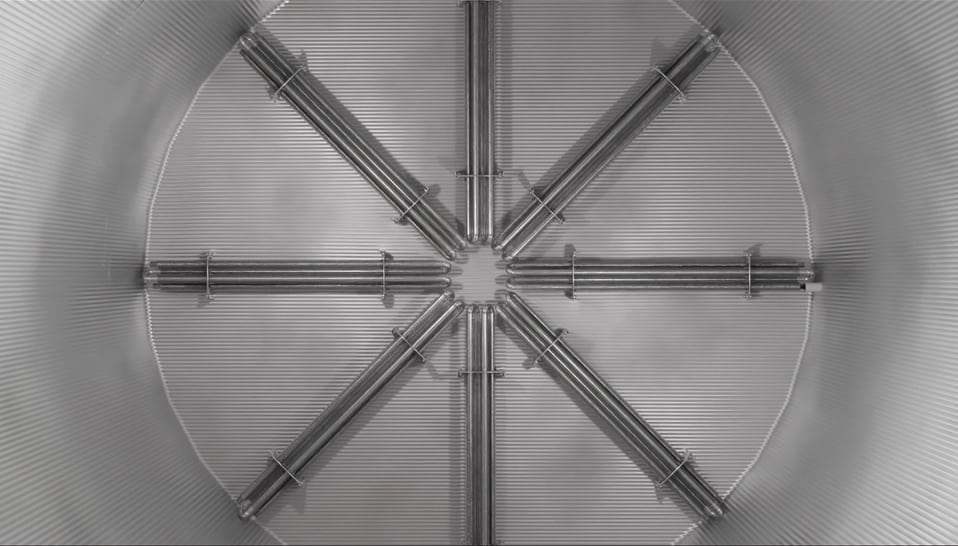

Tank coils sit inside the tank, typically arranged in “banks” across the bottom for even heat distribution. They’re commonly fabricated from carbon steel or stainless steel for durability.

Hot oil, steam, or another heating medium circulates through the coils from an external source (such as a hot oil heater or steam generator) in a continuous loop. This controlled flow transfers heat to—or removes it from—the tank’s contents, maintaining a stable temperature.

Finned vs. Bare Pipe Coils: Which is Right for You?

Choosing between finned and bare coils comes down to efficiency, viscosity, and tank size:

Bare Pipe Coils – A simple pipe or tube, ideal for small tanks, viscous materials, or sanitary applications. They’re more cost-effective in setups that don’t require large heat transfer surfaces.

Finned Coils – These coils have thin fins welded to the pipe (either helically or longitudinally) to dramatically increase surface area—up to 12 times the heat transfer of bare pipe. For large tanks or higher heat loads, finned coils offer unmatched efficiency.

- Helically wound fins are optimal for horizontal installation.

- Longitudinal fins work best in vertical setups.

Hot Oil vs. Steam: Choosing the Heat Source

The heating media moving through the coils can also impact performance:

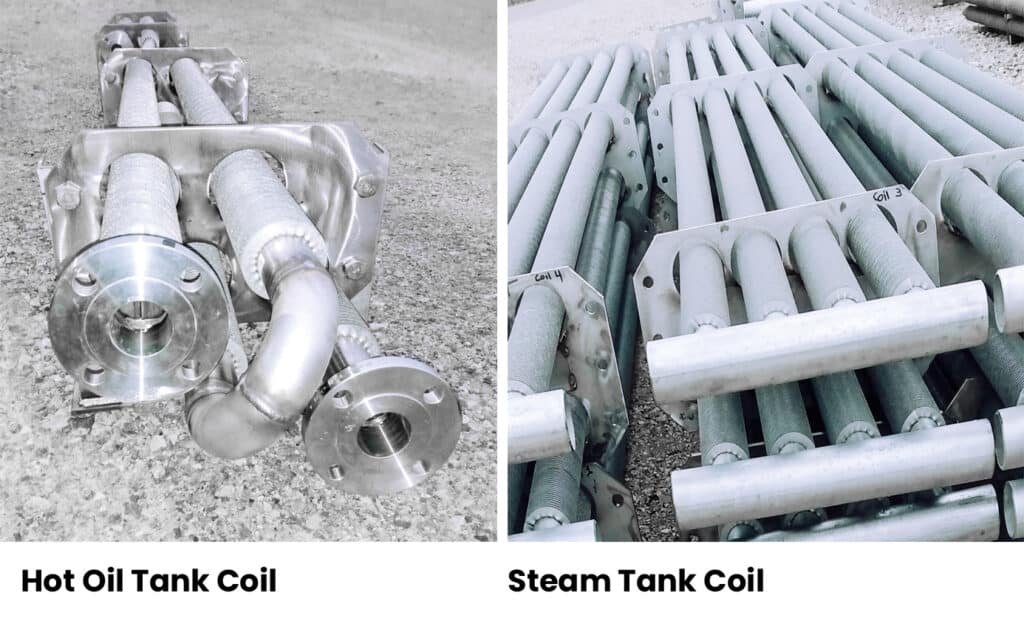

- Hot oil coils are designed to transfer heat to the contents of a tank using hot oil as the heating media. The hot oil flows through the coils in a continuous loop, flowing in a serpentine fashion through the banks of coils. An industrial hot oil heater heats the oil as it passes through the coils. The hot oil then transfers the thermal energy to the stored material and circulates back through the system.

- Steam coils transfer heat using steam as the heating media. Steam from a steam generator makes its way through a header in the tank coil. Steam enters the coil and flows through the bends until it returns to the header and condenses into water. As the steam passes through the pipes, it transfers heat to the stored material in the tank.

Materials of Construction

Material selection depends on your process and environment:

- Carbon steel is an iron alloy that contains a small amount of carbon and very little chromium. It’s strong, durable, and often harder than stainless steel. However, it’s more prone to rust when exposed to moisture or corrosive environments, so it usually requires protective coatings. It’s commonly used in industrial equipment and refining applications where corrosion resistance isn’t a major concern.

- Stainless steel is also an iron alloy but contains at least 10.5% chromium, often with nickel and other elements. This composition gives it excellent corrosion resistance, as the chromium forms a protective oxide layer on the surface. Stainless steel is ideal for sanitary or corrosive environments like food processing, pharmaceuticals, and chemical plants.

Custom Tank Coils for Your Operation

At Enerquip, we design and fabricate custom steam and hot oil coils to meet the demands of your industry. Our solutions are engineered for performance, reliability, and safety—helping you protect your products, reduce downtime, and improve energy efficiency.

Contact us to discuss your application or request a quote for Enerquip’s high-quality tank coils.

More from the Enerquip Blog

- Choosing the Right Industrial Heating Equipment Supplier

- Behind the Burn: How Heat Transfer Systems Refine Aviation Fuel

- How to Store Your Process Equipment Before Installation

- Thermal Fluid Heaters from Enerquip [Videos]

- Industrial Tank Heating Coil FAQs

- How Industrial Heating Equipment Works Through Asphalt Plant Operations [Video]

- Steam Generator FAQs