Heat exchangers are important sanitary and industrial devices that enable heated fluids to be cooled for safe discharge or for cooled fluids to be heated, depending on the need. Learn more about why water heaters require heat exchangers and why they’re crucial across many operations.

What Is a Heat Exchanger?

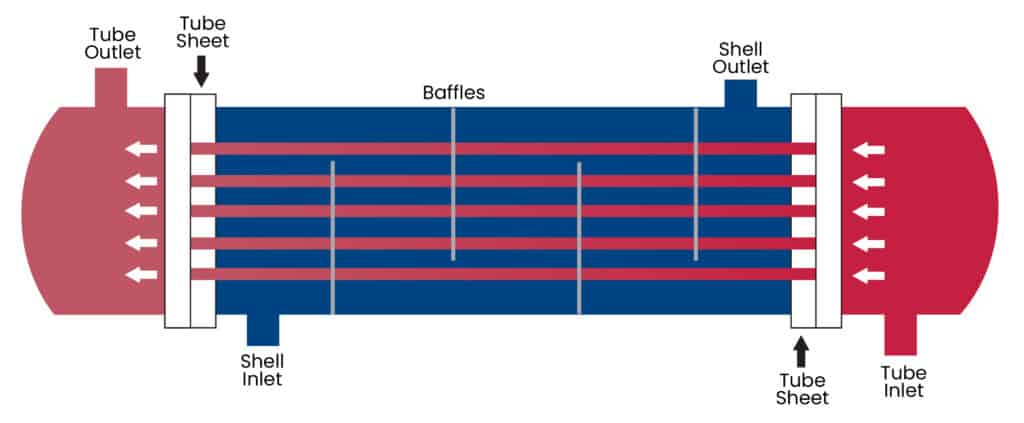

Heat exchangers transfer heat between two or more gases or fluids by containing one of them within the other so that they are in contact but do not mix. For example, a typical water shell and tube heat exchanger setup enables a pipe of hot wastewater to be cooled by placing that pipe inside a wider shell or tank of colder freshwater. As the two streams flow through the system, they exchange thermal energy, so the hot water becomes cooler while the cold water becomes hotter, typically above 100°F.

Often with corrosive nature of water applications, the water contact surfaces are made of stainless steel or higher alloys. Depending on the process conditions, there may be a mix of materials.

How Does a Shell and Tube Heat Exchanger Work in a Water Application?

Water heat exchangers are built from the same basic structure of two nested vessels, in which water in one vessel exchanges thermal energy with fluid in the other. Water heat exchanger systems can be designed in numerous ways, but one of the most common constructions is a shell and tube design, which includes:

Shell: The shell is the outer vessel that contains the tubes and process media. Typically made of stainless steel or carbon steel, the shell holds the incoming fluid and provides support for the heat exchanger. At Enerquip, our ASME code welders routinely weld 316L stainless steel and higher alloys such as Hastelloy and Duplex 2205.

Heat transfer tube or tube bundle: A single tube or bundled individual tubes fit inside the shell, allowing the fluid inside the shell to circulate around it, while another fluid remains inside the tube(s). Bundled tubes allow an increase in surface area for faster heat transfer while maintaining a similar shell size, and they can be replaced without replacing the shell.

Baffles: Baffles are metal plates installed throughout the length of the shell to determine the direction of the shellside flow. In addition, they physically support the tube bundle, help maintain tube spacing, and prevent individual tubes from shaking, breaking, or bending.

As fluid moves through the tubes and the shell, both streams move toward a temperature equilibrium, so that the incoming colder fluid absorbs heat from the hotter fluid, and vice versa. Water heaters use warm wastewater as the fill, which heats the incoming fresh water. A properly functioning water heater saves energy and resources, ensuring that thermal energy is not wasted as the wastewater leaves the system.

Applications for Heat Exchangers

Water heaters are not the only systems that rely on water-to-water heat exchangers for efficient, reliable heat transfer. They can also be used for liquid-to-gas or gas-to-gas heat transfer. Heat exchangers are used in industries and applications such as:

Landfill Gas & Biofuels: Shell and tube heat exchangers are used for cooling and condensing the gas streams, and for vaporizing and heating gas through the various stages of compression and purification.

Pharmaceuticals: High-purity equipment is a must in pharmaceutical applications. Shell and tube heat exchangers are used as product heaters and coolers, in clean-in-place systems, and in the heating and cooling of water for injection (WFI).

Food and beverage processing: Heat exchangers help keep food and beverages—like wort in beer brewing—cool. Companies need heat exchanger systems to control the safety and integrity of their products and maintain regulatory compliance.

Asphalt: Construction companies require effective, heavy-duty heat exchangers for asphalt heating operations.

Cannabis processing: Heat exchangers for processing hemp and cannabis oils must be sanitary and able to perform repeated extraction, cooling, condensing, and superheating.

Chemical processing: Shell and tube heat exchangers and condensers are used in the petroleum and chemical industries to condense a variety of chemical vapors.

Personal Care: Heat exchangers are used to heat and cool pure water that is used for the preparation of products typically to be used topically or by ingestion, and for the cleaning of those product-contact components.

Swimming pools: Heated swimming pools also rely on heat exchanger systems.

HVAC: Air conditioning and refrigeration systems use heat exchangers to transfer thermal energy between the interior and exterior of a home or building via air ducts. Automobiles, aircraft, and trains also use heat exchangers in their HVAC systems to regulate temperature and ventilation.

Why Choose Enerquip?

At Enerquip, our stock and custom heat exchangers meet the precise needs of our customers across every industry. Our systems are designed to be easy to install, maintain, and clean. We can design systems to meet your current or future requirements while remaining compliant with regulatory standards, including food- and pharmaceutical-grade systems.

Request a quote or contact us today to discuss your heat exchanger needs.