In recent years, the demand for plant-based milk alternatives has skyrocketed, transcending beyond vegan and dietary-conscious consumers. And while this “milk” isn’t really milk, but more of a plant juice, their popularity continues to rise.

In 2020, approximately 35% of American households embraced plant-based milk, and this trend continues to surge. While plant-based milk options such as coconut, almond, soy, hemp, and oat milk have gained modern popularity, their origins trace back to historical times. Almond milk was a staple in medieval European cuisine, while soy milk has a history spanning over a millennium in China. Nordic countries have enjoyed oat milk for centuries, often used as a creamy beverage or porridge base.

Today’s interest in plant-based milk represents a return to these traditional, plant-derived dairy alternatives driven by health and sustainability concerns.

As the demand for dairy-free and eco-friendly options grows, manufacturers are investing in innovative production methods. Central to these processes are shell and tube heat exchangers, which play a crucial role in pasteurizing plant-based milk products to ensure consumer safety. In this article, we’ll delve into the unique process conditions required for plant-based milk production.

Shell and Tube Heat Exchanger: The Key Player

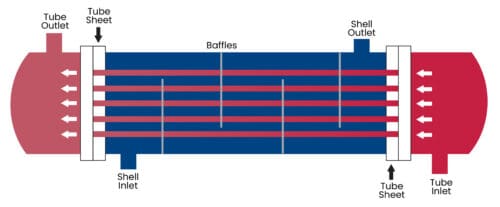

Before delving into the specifics of processing plant-based milk, let’s briefly understand the shell and tube heat exchanger. This piece of equipment is a critical component in various industries, including food, beverage, and dairy processing. It consists of a series of tubes housed within a cylindrical shell. One fluid or steam flows through the tubes (the ‘tube side’ fluid), while another flows around the tubes within the shell (the ‘shell side’ fluid). Heat transfer occurs between the two, enabling the efficient cooling or heating of one while preserving the other’s temperature.

With a different composition, the production process will also be different between plant-based milk and dairy milk. But what are the differences? Keep reading.

Plant-Based vs. Dairy Milk Production

Dairy milk and plant-based milk are produced through distinct processes owing to their different sources. Dairy milk production begins with the milking of animals, usually cows, but can also be from buffalo, goats, sheep, and more. Following collection of the raw milk, the product will be pasteurized, homogenized, sanitized, and packaged. The pasteurization process ensures safety while preserving nutrients, and homogenization evenly disperses fat throughout the milk. Dairy milk is then packaged for distribution in various forms.

Conversely, plant-based milk production commences with the preparation of the primary plant-based ingredient, varying depending on the milk type (e.g., almonds, rice, soybeans, and so many more!). After ingredient preparation, the plant material is blended with water to create a milk base, which may undergo straining or separation for smoother textures. Plant-based milks are pasteurized, homogenized, fortified, and then packaged. The production equipment for plant-based milk differs to accommodate unique plant ingredients.

Plant-Based Milk Production Process

Plant-based milk production involves several steps, including soaking, grinding, mixing, and pasteurization. The shell and tube heat exchanger comes into play during the pasteurization and cooling phases.

Preheating

Before pasteurization, plant-based milk alternatives are typically preheated. This step is crucial for maintaining the milk’s quality and flavor. The plant-based milk is heated as it passes through the tubes of the heat exchanger. The shell-side fluid, often hot water or steam, surrounds the tubes, transferring heat to the milk. Careful control of temperature is essential, as overheating can lead to undesirable changes in flavor and texture.

Pasteurization

Pasteurization is a critical step that ensures the safety of plant-based milk, and dairy milk alike, by eliminating harmful bacteria and enzymes. The heat exchanger is used to rapidly heat the milk to the desired pasteurization temperature. This process destroys pathogens while preserving the milk’s nutritional content.

Cooling

After pasteurization, the milk must be rapidly cooled to halt the cooking process and maintain its freshness. The shell and tube heat exchanger is again employed, but this time, typically cold water or a glycol solution flows through the tubes, efficiently cooling the milk within the shell. The precise control of cooling rates is essential to prevent post-pasteurization bacterial contamination and maintain the desired product characteristics.

Unique Considerations for Plant-Based Milk

Plant-based milk presents some unique challenges and considerations for the use of shell and tube heat exchangers:

Viscosity

Plant-based milks like almond or oat milk tend to be more viscous, or thicker, than traditional dairy milk. The heat exchanger’s design must account for this difference to ensure efficient heat transfer and prevent clogging or fouling of the tubes.

Cleanliness

Plant-based milks can contain particulates or plant matter that may pose challenges in terms of fouling and cleanliness. Regular maintenance and cleaning of the heat exchanger are essential to prevent contamination and maintain product quality. Many facilities invest in clean-in-place (CIP) skids to thoroughly clean and sanitize, without manual operation.

Flavor Preservation

The sensitive flavors of plant-based milks can be affected by temperature changes. Precise temperature control during heating and cooling is crucial to preserving the desired taste and texture.

Learn more about the vital production steps to ensure a safe, quality product.

The production of plant-based milk alternatives like coconut, almond, and oat milk relies on efficient and precise processes. The shell and tube heat exchanger plays a pivotal role in achieving the necessary pasteurization and cooling, while also addressing unique challenges related to viscosity, cleanliness, and flavor preservation.

Ready to talk about your specific processing conditions and needs? We invite you to contact us or request a quote today.

More from the Enerquip Blog

- Plant Steam vs. Culinary Steam vs. Pure Steam. What’s the difference?

- The importance of food safety in processing plants

- Decoding the Delicate Balance of Sizing Shell and Tube Heat Exchangers

- Exchanger System Helps Food Packager Put the Soup On

- Tips for preventing food recalls from your production facility

- Enerquip Testimonial: New Glarus Brewing Company

- Preventing Cross Contamination in Your shell and tube heat exchangers