Our pets hold a special place in our hearts, and we want nothing but the best for them. Ensuring their happiness and well-being includes providing them with safe and nutritious food. In this article, we’ll delve into the world of pet food safety and quality and explore how cutting-edge heat exchange solutions are the unsung heroes that make it all possible.

Ensuring Quality in Pet Food Processing

The pet food industry has witnessed explosive growth, offering an array of products tailored to our pets’ unique dietary preferences and health needs. But with this expansion comes the question of whether quality and safety are keeping up with demand. Much like human food, guaranteeing the production of safe and nutritious pet food is paramount.

Ongoing research and innovation in pet food processing aim to improve the quality and safety of pet food. This includes advancements in packaging, ingredient sourcing, and manufacturing technology. Stringent quality control measures are employed to ensure the safety of pet food. This includes testing for contaminants, such as bacteria, mold, and mycotoxins, to prevent foodborne illnesses in pets.

Just like human food, pet food is subject to regulation by government agencies to ensure its safety and quality. In the United States, for example, the Food and Drug Administration (FDA) oversees pet food standards and labeling.

Manufacturing Process and Pet Health

Producing pet food involves a series of crucial steps, including cooking, pasteurization, and sterilization. These processes demand precise temperature control to eradicate harmful pathogens while preserving the nutritional value of the ingredients. Let’s dive into the key processes that ensure your pets’ safety.

Precise Temperature Control

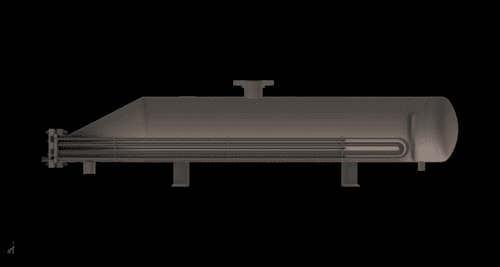

Shell and Tube Heat Exchangers, in particular, are instrumental in maintaining precise temperature control during various stages of pet food manufacturing. This is crucial for pet food safety as it helps in:

Pathogen Elimination: Cooking and pasteurization require specific temperatures to eliminate harmful pathogens, such as Salmonella and E. coli, which can be present in raw ingredients. Shell and tube heat exchangers ensure that the food reaches and sustains these critical temperatures, making the final product safe for pets.

Nutrient Preservation: While eliminating pathogens, it’s equally important to retain the nutritional value of the ingredients. Precise temperature control prevents overcooking or overheating, which can degrade essential nutrients in pet food.

Enerquip Sanitary Shell & Tube Heat Exchangers for Food Production

Energy Efficiency and Waste Reduction

Waste Heat Economizers, heat exchangers, bayonet heaters, and suction heaters play a significant role in improving the energy efficiency of the manufacturing process. Here’s how:

Reduced Environmental Impact: By capturing and reusing waste heat, economizers reduce the overall energy consumption of the manufacturing process. This not only lowers operational costs but also decreases the environmental footprint, which is essential for sustainability and long-term safety.

Increased Energy Efficiency: Shell and tube heat exchangers enhance energy efficiency and reduce environmental impact by efficiently transferring heat between two fluid streams, such as hot and cold liquids or gases. Their design maximizes surface area for heat exchange, which minimizes energy consumption and thus reduces the overall environmental footprint of industrial processes and systems.

When trying to create efficiency within a tank of contents, bayonet heaters and suction heaters are highly efficient choices. Bayonet heaters are designed to heat an entire tank of contents, while suction heaters provide heat only as the product is removed from a tank. Both options regulate the temperature on an as needed basis.

Enerquip Waste Heat Economizer

Consistent Heat Sources

Thermal Fluid Heaters and Steam Generators are essential for providing consistent and controlled heat sources throughout the manufacturing process:

Consistency in Cooking and Pasteurization: Maintaining a consistent heat source ensures that pet food is cooked evenly and thoroughly. This consistency is vital for eliminating any potential cold spots in the food that could harbor harmful bacteria.

Steam Sterilization: Steam generators produce clean and controlled steam, which is often used for sterilization or to regulate heat. Steam sterilization is a critical step in ensuring that pet food is free from harmful microorganisms.

An inside view of an Enerquip Steam Generator. Hot oil flows through the tubes, while the tube bundle sits in water. When the two collide, steam is generated and flows up and out to be distributed as clean steam.

Hygienic Processing

When it comes to pet food safety and quality, maintaining a high level of hygiene throughout the manufacturing process is of utmost importance. Clean-in-place (CIP) heaters are a vital component in achieving this goal.

Ensuring Sterility: Clean-in-place heaters are designed to efficiently heat and sanitize equipment and pipelines. In pet food processing, maintaining a sterile environment is non-negotiable. CIP heaters play a crucial role in achieving this by ensuring that all surfaces and components that come into contact with pet food are thoroughly cleaned and sanitized. This process helps prevent contamination and ensures that each batch of pet food is safe for consumption.

Compliance with Regulations: Much like other aspects of pet food processing, the cleanliness of equipment and pipelines is subject to regulatory scrutiny. Using CIP heaters helps pet food manufacturers meet and exceed hygiene standards set by government agencies, ensuring that their products are in compliance with safety regulations.

Enerquip CIP (Clean in Place) Heaters

Storage and Preservation

Tank Heating Coils contribute to safety during the storage and preservation of pet food by maintaining the desired temperature in storage tanks. Proper temperature control prevents any potential growth of bacteria or contaminants during storage.

Enerquip Stainless Steel Bare Pipe Tank Heating Coils for Sanitary Applications

By incorporating these advanced heat exchange solutions into the pet food manufacturing process, manufacturers can ensure that every batch of pet food is not only delicious but also meets the highest standards of safety. These technologies help safeguard pets from foodborne illnesses while also reducing the environmental impact of production, making the industry safer and more sustainable for the long term.

Efficient Manufacturing Process Solutions from Enerquip Thermal Solutions

As the demand for high-quality pet food continues to soar, the role of innovative heat exchange solutions becomes increasingly critical. Together, we can ensure that every meal our beloved pets enjoy is not only delectable but also safe and nutritious.

Contact us or request a quote today to put our decades of experience to work for you and your furry friends.

More from the Enerquip Blog

- Decoding the Delicate Balance of Sizing Shell and Tube Heat Exchangers

- Discover the Hidden Brilliance of Metal Surfaces: Unleash the Power of Electropolishing

- Why Excel Engineering Chooses Enerquip [Video]

- Understanding Finish Requirements for Shell and Tube Heat Exchangers

- Tips for preventing food recalls from your production facility