Maple Syrup Producers Use Heat Exchangers to Improve Production

Leave a CommentThe Science and Innovation Behind Maple Syrup Production

Maple syrup is a beloved topping for pancakes, waffles, and countless other treats. While its rich, sweet flavor remains timeless, the process of making maple syrup is constantly evolving. Producers have a limited window each year to harvest sap and transform it into syrup, making efficiency and innovation key to success.

The Fleeting Sugaring Season

Sugaring season begins when winter transitions into spring, creating warm days and freezing nights. This temperature fluctuation causes sap to flow from maple trees, a process that continues until nighttime temperatures remain above freezing and buds begin to form. Once the sap becomes bitter, the season comes to an end.

Since weather patterns shift annually, sugaring season can vary in duration. An early spring may lead to an early start, while a sudden warm spell can shorten the season significantly. Because of this unpredictability, syrup producers must work quickly and efficiently to maximize their yield.

Speeding Up the Sap Production Process

To make the most of sugaring season, producers have developed innovative methods to speed up and refine the syrup-making process. One such approach involves using indirect heat systems to accelerate evaporation. Some producers employ steam-craft technology to pre-boil the sap, significantly reducing the time needed for evaporation compared to traditional direct-heat methods.

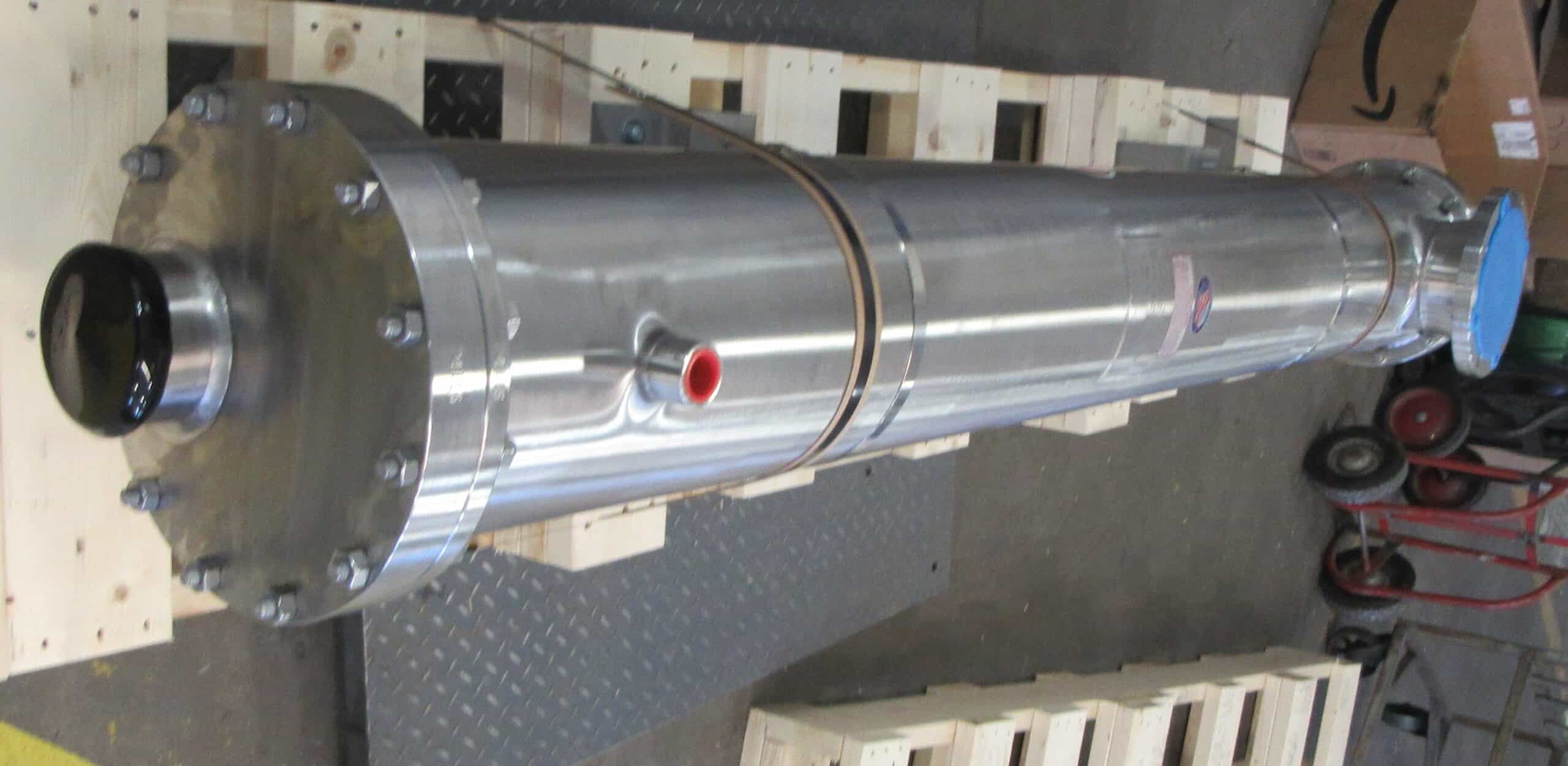

Many producers also use sanitary shell and tube heat exchangers to pasteurize syrup, making it less viscous and easier to bottle while removing potential contaminants. Another widely adopted method is reverse osmosis (RO), which concentrates the sap before it enters the evaporator. RO technology improves efficiency by reducing the time and energy needed for evaporation, allowing producers to decrease fuel consumption while maintaining syrup quality.

Saving Energy During Syrup Production

Since syrup production is consolidated into a several-week-long sprint, condensed operations demand high energy spend. While more syrup producers are utilizing RO technology, there are other ways producers can save energy.

A large amount of water needs to be removed from sap to make syrup. Because of this, the syrup-making process gives off incredible amounts of steam. The steam released provides a convenient and free heat source that producers are beginning to take advantage of.

By installing a shell and tube heat exchanger, syrup manufacturers can capture the heat lost to rising steam and use it to preheat the sap before it reaches the evaporator. Like RO, this process will reduce the amount of time the sap needs to spend in the evaporator before it reaches the desired consistency.

This mechanism was perfected in 1974 by George Raithby of the University of Waterloo in Ontario. Prior to Raithby’s development, the use of any equipment above the evaporator would compromise the final product because rising steam would condense on the metal surface and drip back into the open pans of syrup. Raithby used a shell and tube heat exchanger with a drip pan installed beneath it to collect the condensate. Inside the tubes, the sap could be heated from a starting temperature of about 40 degrees Fahrenheit to around 190 degrees Fahrenheit before it reaches the evaporator.

Today, modern stainless steel heat exchangers continue to enhance durability and performance in maple syrup production.

Making the Most of Sugaring Season

Sugaring season may be short, but its impact is long-lasting for both producers and syrup lovers alike. Innovations in heat transfer technology, reverse osmosis, and energy efficiency help producers optimize their operations and ensure a steady supply of high-quality syrup. If you’re looking to improve your syrup production process, consider investing in a shell and tube heat exchanger. Reach out to the engineers at Enerquip to explore how this technology can enhance your operation.

From the Enerquip Blog

Tube Side or Shell Side: Comparing Fluid Allocation Options for Your Shell and Tube Heat Exchanger

How Static Mixers & Turbulators Improve Heat Exchanger Efficiency

3 Shell & Tube Heat Exchanger Features That Affect Shell-Side Pressure Drop

Shell and Tube Heat Exchangers: A Guide to Industry Standards

No manufacturer or equipment operator wants to have leaks. But for pharmaceutical processing equipment, leaks are particularly troublesome. Leaks create the possibility of product contamination, as well as corrosion or other chemical reactions that may occur when process and utility fluids mix.

No manufacturer or equipment operator wants to have leaks. But for pharmaceutical processing equipment, leaks are particularly troublesome. Leaks create the possibility of product contamination, as well as corrosion or other chemical reactions that may occur when process and utility fluids mix.