Snow melt coils, also known as snow melting systems or heating coils, are commonly used to melt snow on parking lots and sidewalks. A less common, but practical use, is for melting ice and slush in slush pits outside large ice areas.

Slush pits are typically designed to collect melted snow and ice from ice resurfacing machines after cleaning off rinks. The slush and ice are stored until they can be properly drained as wastewater or treated and recycled.

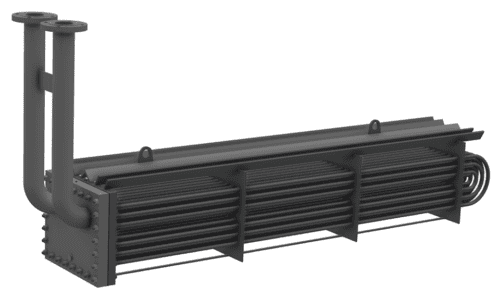

Snow melt coils are placed in the bottom of a tank or pit, with vertical connections long enough to rise above the surface of the pit. They are then connected to a heating system that pumps a hot liquid, such as hot oil or glycol solutions, through the tubes, effectively warming the pit to melt the slush and ice.

Benefits of snow melt coils for slush pits

From efficient slush removal and rapid drainage to minimized freezing risks and improved hygiene, snow melt coils are transforming the way ice arenas handle slush, creating a more convenient and hygienic environment for both staff and patrons. Let’s delve into the benefits and discover how snow melt coils are making a significant impact on slush pit operations.

Slush removal: The primary benefit of snow melt coils in a slush pit is the ability to accelerate the melting process of the accumulated slush. The coils generate heat, facilitating the conversion of the slush into liquid form, which can then be drained or treated more easily.

Efficient slush management: By melting the slush within the pit, you reduce the amount of space required for storage. This can be particularly beneficial in areas with limited space or when dealing with large volumes of slush.

Rapid slush removal: Traditional methods of slush removal, such as manual shoveling or pumping, can be time-consuming and labor-intensive. Snow melt coils expedite the process, allowing for quicker removal of the slush, especially if combined with an effective drainage system.

Minimized freezing risks: If the slush pit is prone to freezing, having snow melt coils installed help prevent the slush from refreezing and forming ice. This can reduce the risk of slippery surfaces and improve overall safety.

Improved hygiene: Slush can often contain dirt, debris, and pollutants, making it unsanitary. By melting the slush with the help of snow melt coils, you can facilitate the removal of contaminants, leading to a cleaner and more hygienic environment.

Design Considerations of Snow Melt Coils

When it comes to the construction of snow melt coils for slush pits, careful consideration must be given to the choice of materials, durability, heat output, and more. The following factors play a crucial role in ensuring the efficient and effective operation of snow melt systems in managing slush accumulation.

Material of construction: Snow melt coils must be built of durable, heat-conductive materials like copper, aluminum, or at Enerquip, stainless steel. Stainless steel is particularly suitable for harsh environments or applications where corrosion resistance is crucial. The specific material used for snow melt coils can vary depending on factors such as the application, budget, and regional climate.

Durability: With heavy ice and slush falling onto the surface of the snow melt coils, several diagonal plates must be welded over the tube bundle. These fins take the brunt of the weight, which protects the tubes from being crushed or damaged. The top row of tubes is also typically made with heavier wall tubes to further minimize the risk of damage.

Heat output and capacity: Slush pits are typically larger in size compared to traditional snow melt applications. Therefore, it’s essential to calculate the required heat output and capacity of the coils to melt the accumulated slush within a reasonable timeframe. Factors such as the volume and thickness of slush, ambient temperatures, and desired melting rate should be taken into account during the design process.

Coil placement and coverage: The positioning of the coils within the slush pit is critical to ensure uniform heat distribution and efficient melting. The coils should be strategically placed to cover the entire surface area of the pit. Consideration should also be given to the depth at which the coils are installed to ensure effective heat transfer to the slush.

Heat source and energy efficiency: Selecting an appropriate heat source is important to ensure efficient operation and minimize energy consumption. Common heat sources for snow melt systems include hot oil, glycol solutions, electricity, natural gas, or geothermal energy. The heat source should be chosen based on factors such as availability, cost-effectiveness, and environmental considerations.

Control system: Implementing a reliable control system is crucial to managing the operation of the snow melt coils. The control system should include temperature sensors or feedback mechanisms to monitor the slush temperature and adjust the heat output accordingly. This helps prevent excessive heating and ensures efficient energy usage.

Drainage system: A well-designed drainage system is essential to effectively remove the melted slush from the pit. Proper slopes, drain outlets, and pipes should be integrated into the slush pit design to facilitate efficient drainage and prevent refreezing.

Maintenance access: Consider the ease of maintenance and access to the snow melt coils within the slush pit. Coils may require periodic inspection, cleaning, or potential repairs. Ensuring that the coils are accessible for maintenance personnel is important for the long-term functionality of the system.

Safety considerations: Safety should always be a priority when designing snow melt systems. Ensure that all electrical components, wiring, and connections are properly installed and insulated to prevent any hazards. Additionally, proper signage and barriers should be in place to alert individuals to the presence of heated surfaces.

Snow Melt Coils from Enerquip

For decades, Enerquip has been providing snow melt coils to arenas across the United States.

Implementing snow melt coils within a slush pit requires careful consideration of factors such as coil placement, heating capacity, maintenance access, and energy consumption. Consulting with a professional engineer is crucial to ensure the system’s effectiveness and feasibility.

Ready to speak with an Enerquip expert about your snow melt needs? Get started. Request a quote today.